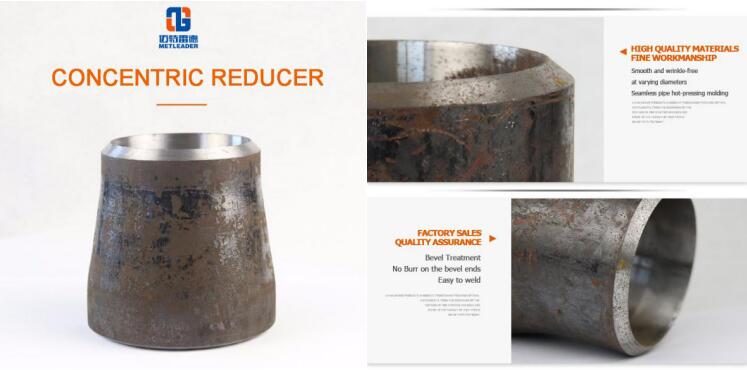

Concentric pipe reducer

Concentric pipe reducer

The material of the concentric pipe reducer is performed by ASTM A106/a53 Grb,api 5L, APT5CT, ASTM A105, ASTM A234, ASTM A106, DIN German standards and customer requirements. The roundness of the reducer should not be greater than 1% of the corresponding end diameter, and the allowable deviation is ±3mm. Recently our customers by the size of my company’s supply of the head, affirmed the quality of our products, and to add orders.

The concentric reducer is shaped like 八, and it is used in a vertical piping system. Due to changes in the diameter of the pipe, it can lead to fluid flow or other sudden changes. When designing a piping system, engineers should consider all the circumstances. If the system needs to avoid sudden, the concentric reducer should be the first choice. The pressure will be flowing through the joint of the concentric reducer, which can stabilize the pipe. Shape concentric reducers are uniform and therefore easier to produce than eccentric reducers, with lower costs and prices. The butt welding reducer is made directly from the steel pipe and is used for ordinary dimensions. Larger sizes of more than 24 inches will be made of steel plates.

Technology of concentric pipe reducer:

Concentric pipe reducer is a kind of pipe fitting for the diameter of the pipe. Generally used in the forming process for reducing the size of compression, expansion of the compression or reduction of diameter and expansion of pressure, for certain specifications of different diameter pipe can also be used stamping forming.

1.Shrink diameter process

The shrinkage forming process of the reducer is to put the Tube billet with the same big diameter of the reducer into the forming die, and then the metal can be formed along the mold cavity by pressing along the axial direction of the tube billet. According to the size of the reducer, it is divided into one pressing forming or several pressing forming. The figure below is a schematic diagram of the necking forming of concentric reducer.

2.Enlarging the diameter process

The enlarged diameter of the tube billet is smaller than the big-diameter of the reducer, and the inner diameter of the tube billet is formed by the internal die.

The expanding process mainly solves the situation that the reducer with large diameter is not easy to be formed by reducing diameter, and it is sometimes combined with the method of enlarging diameter and reducing diameter according to the need of material and product forming. In the process of shrinking or expanding deformation, the cold pressure or hot pressing is determined according to different material and changing diameter.

Under normal circumstances, as far as possible the use of cold pressure, but a number of variable diameter caused by serious processing hardening of the situation, the thickness of the thickness of the case or alloy steel materials should use hot pressing.

3.Stamping process

In addition to the use of steel pipe for the production of reducer, some of the specifications of the reducer can also be used to produce steel sheet stamping process.

Guarantee the product’s process, can guarantee the product quality. As the production of carbon steel pipe parts 36 years of senior manufacturers, our company’s advanced technology and efficient, in improving product quality at the same time, reduce the cost of products, let customers.

Therefore, our customers are for many years the continuous cooperation of customers, our products at ease, the credibility of our company more trust. New and old customers friends, if you have any questions about the concentric pipe reducer, you can always consult us. We will give you the quickest reply, the best quotation, the most comprehensive service.The shape of the die used for stretching refers to the design of the surface dimension of the different diameter tube, stamping and drawing of the sheet steel after punching.