Seamless steel pipe for oil drilling-N80 oil casing

Contents

- What is N80 oil casing

- N80 oil casing materials and performance

- N80 oil casing specifications and classification

- N80 oil casing production process

- N80 oil casing advantages

- N80 oil casing application

- Summary

N80 oil casing is an important equipment for oil drilling, with wide applications and important technical characteristics.

The following is a detailed introduction to N80 oil casing:

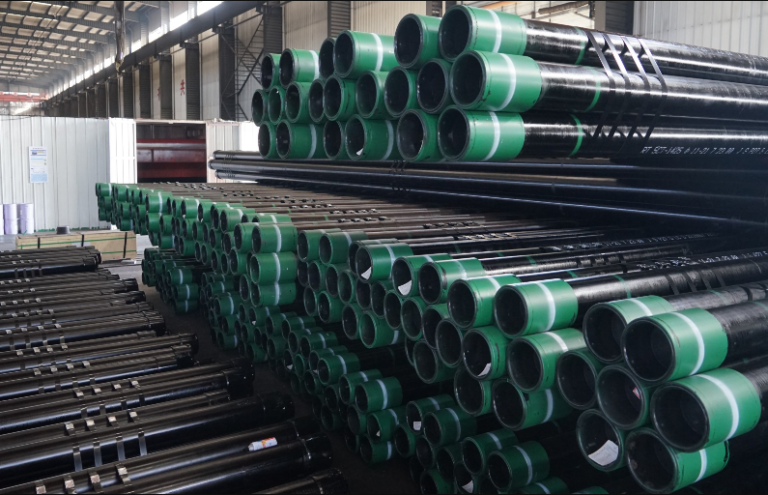

What is N80 oil casing

N80 oil casing is a device used to support the well wall during drilling and after completion to ensure the smooth progress of the drilling process and the normal operation of the entire oil well after completion.

N80 oil casing materials and performance

N80 oil casing is usually made of high-quality steel, such as 42MnMo7 steel, which has high strength, high toughness and good corrosion resistance and can withstand high pressure and high temperature during drilling.

Performance parameters:

Elongation: 0.5%

Yield strength: 552–758MPa

Tensile strength: 689MPa

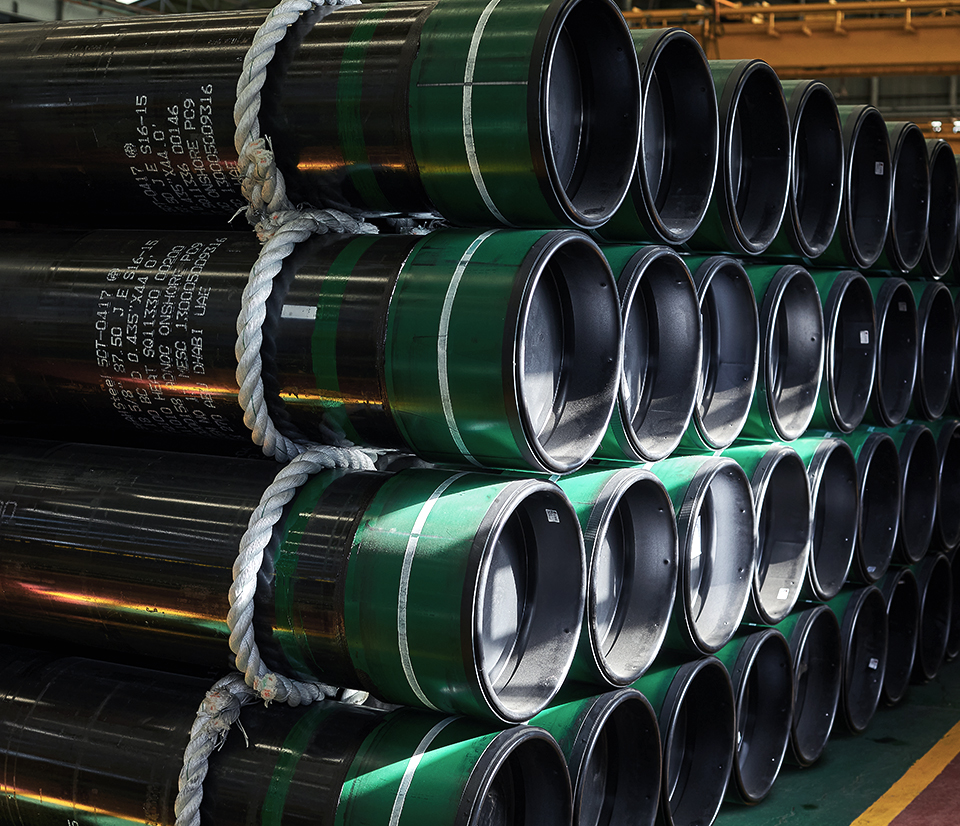

N80 oil casing specifications and classification

Specification range:

Outer diameter: 114.3MM-508MM (4 1/2″-20″)

Wall thickness: 5.21MM-16.13MM (9.5PPF-133PPF)

Classification:

By thread type: short thread casing and long thread casing

By material and performance: N80-1, N80-Q and other types

N80 oil casing production process

The production process of N80 oil casing involves multiple links, including raw material preparation, smelting, rolling, heat treatment, processing and inspection, etc.

The specific process flow may vary depending on the manufacturer and product requirements, but generally includes the following key steps:

- Raw material preparation: Select high-quality steel that meets the requirements as raw materials.

- Smelting: Obtain molten steel that meets the requirements through the smelting process.

- Rolling: Cast the molten steel into a tube billet, and obtain the steel pipe of the required specifications and shape through the rolling process.

- Heat treatment: Heat treatment is performed on the rolled steel pipe to improve its mechanical properties and corrosion resistance.

- Processing: Process the heat-treated steel pipe, including threading, chamfering, cutting, etc., to meet different usage requirements.

- Inspection: Strict inspection and testing of the finished product to ensure that it meets the relevant standards and requirements.

N80 oil casing advantages

High-precision processing: N80 oil casing adopts advanced processing technology, with high diameter accuracy, smooth inner wall, good joint sealing, which can ensure the sealing of oil, gas and water layers during drilling.

Long life: Due to its excellent material and processing technology, N80 oil casing has a long service life, which can reduce the number of casing replacements and improve drilling efficiency.

Strong adaptability: N80 oil casing is suitable for various complex geological conditions and drilling environments, and can work stably under high pressure, high temperature and high corrosive environment.

Easy installation: The design of N80 oil casing makes installation convenient and quick, which can effectively shorten the drilling cycle and reduce drilling costs.

Environmental protection: N80 oil casing has little impact on the environment during production and use, which meets the environmental protection requirements of modern industry.

N80 oil casing application

N80 oil casing has a wide range of application prospects in the oil drilling industry. With the continuous development of oil exploration technology and the continuous increase in drilling depth, the requirements for oil casing are getting higher and higher.

N80 oil casing has become an ideal choice for the oil drilling industry with its excellent performance and wide range of applications.

In the future, with the continuous advancement of technology and the continuous expansion of the market, the application prospects of N80 oil casing will be even broader.

Summary

N80 oil casing is an important equipment for oil drilling, with the characteristics of excellent material, high-precision processing, long life, strong adaptability, easy installation and environmental protection.

It has a wide range of applications and important technical value in the oil drilling industry.