An article to help you understand the classification of steel pipes

Catalog

There are many ways to classify pipes. According to the material, they can be divided into metal pipes, non-metal pipes and steel-lined non-metal composite pipes.

Non-metal pipes mainly include rubber pipes, plastic pipes, asbestos cement pipes, graphite pipes, fiberglass pipes, etc.

The proportion of non-metal pipes used is smaller than that of metal pipes, while metal pipes account for more than 85% of all process pipeline installation projects in most petrochemical plants. Today, I will focus on introducing metal pipes.

Welded steel pipe

Welded steel pipes, also known as seam steel pipes, are generally made of steel plates or steel strips rolled and welded.

Surface treatment

There are two types: galvanized and non-galvanized. The galvanized surface is white, also known as white iron pipe or galvanized steel pipe; the non-galvanized surface is ordinary welded steel pipe, also known as black iron pipe.

Galvanized welded steel pipe is often used for pipelines that require relatively clean media, such as domestic water, purified air, instrument air, etc.; non-galvanized welded steel pipe can be used to transport steam, gas, compressed air and condensed water, etc.

Welded steel pipes can be divided into two types when leaving the factory

One is with threaded ends, and the other is without threaded ends.

The length of each welded steel pipe with threaded ends is 4 to 9 meters, and the length of each welded steel pipe without threaded ends is 4 to 12 meters.

Welded steel pipes are classified according to different wall thicknesses

It is divided into thin-walled steel pipe, thickened steel pipe and ordinary steel pipe. Ordinary steel pipe is the most commonly used in process pipelines, and its test pressure is 2.0MPa. The test pressure of thickened steel pipe is 3.0MPa.

There are many ways to connect welded steel pipes.

There are threaded connection, flange connection and welding. Flange connection is divided into threaded flange connection and welded flange connection, and welding method is divided into gas welding and arc welding.

Specification range of commonly used welded steel pipes:

Nominal diameter 6~150mm

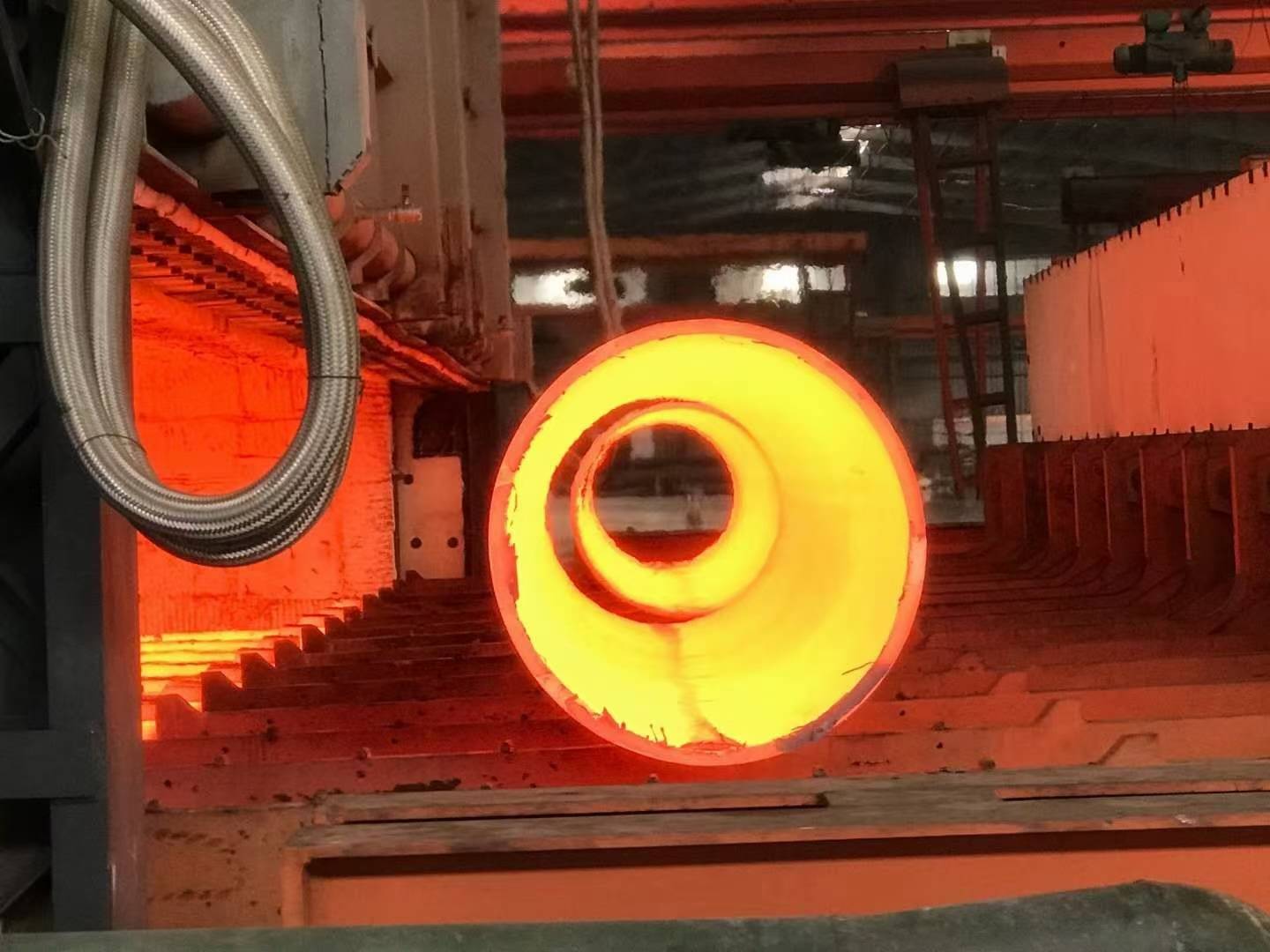

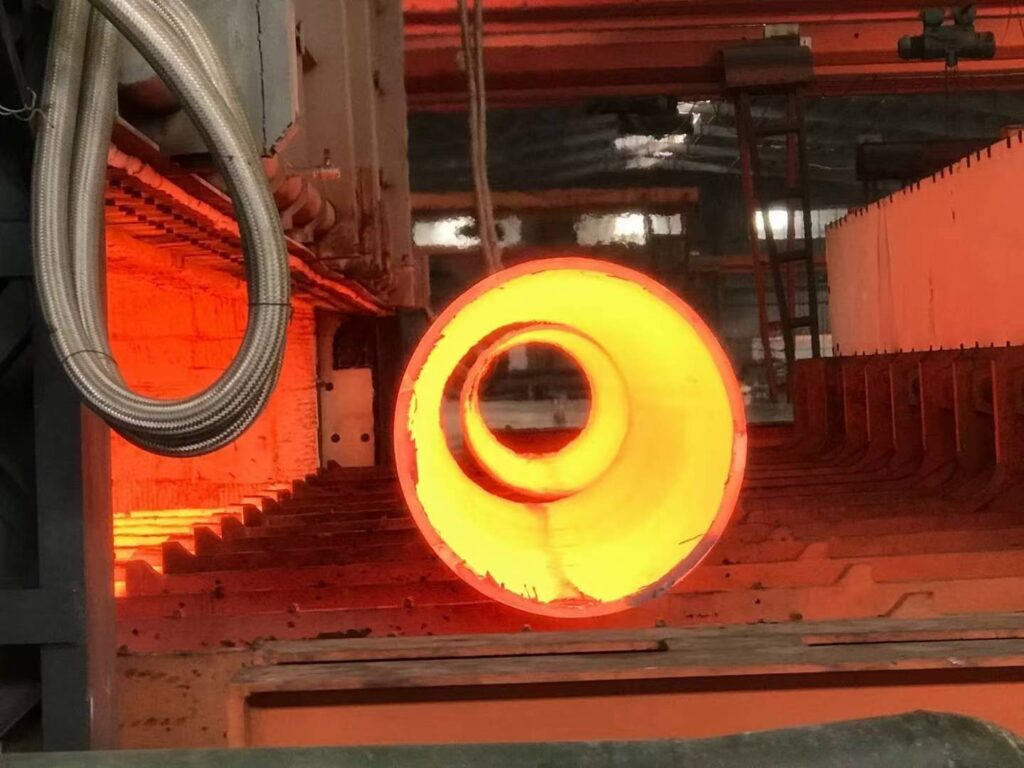

Seamless steel pipe

Seamless steel pipe is the most widely used pipe in industrial pipelines with the most varieties and specifications.

There are two categories of seamless steel pipes: seamless steel pipes for fluid transportation and seamless steel pipes with special features.

The former are commonly used steel pipes for process pipelines, and the latter are such as special steel pipes for boilers, cracking furnace tubes and steel pipes for heat exchangers.

According to the material can be divided into

Carbon seamless steel pipes, chrome-molybdenum seamless steel pipes and stainless and acid-resistant seamless steel pipes.

According to the nominal pressure, it can be divided into:

There are three types: low pressure (0≤1.0MPa), medium pressure (1.0<10MPa=), and high pressure (≥10MPa).

Carbon seamless steel pipe

Commonly used manufacturing materials are No. 10, No. 20, and 16Mn steel.

Its specifications range from hot-rolled outer diameter φ32 to 630mm, cold-drawn outer diameter φ6 to 200mm, single tube length 4 to 12m, and allowable operating temperature of -40 to 450℃.

It is widely used to transport various media that are non-corrosive to steel, such as steam, oxygen, compressed air, oil products, and oil and gas.

Low alloy steel seamless steel pipe

Alloy steel pipes containing a certain proportion of alloy elements.

Usually divided into two types:

one is a low alloy steel pipe containing manganese elements, called ordinary low alloy steel pipe, such as 16Mn, 15MnV, etc.;

the other is a low alloy steel pipe containing chromium, molybdenum and other elements, called chrome-molybdenum steel pipe. Commonly used are 12CrMo, 15CrMo, 12Cr2Mo, 1Cr5Mo, etc., with specifications ranging from outer diameter φ10 to φ273mm, single tube length 4 to 12m, and chrome-molybdenum steel pipes are suitable for temperature ranges of -40 to 550℃.

Low alloy seamless steel pipes are mostly used to transport various high temperature oils, oil and gas, non-corrosive salt water, low-concentration organic acids, etc.

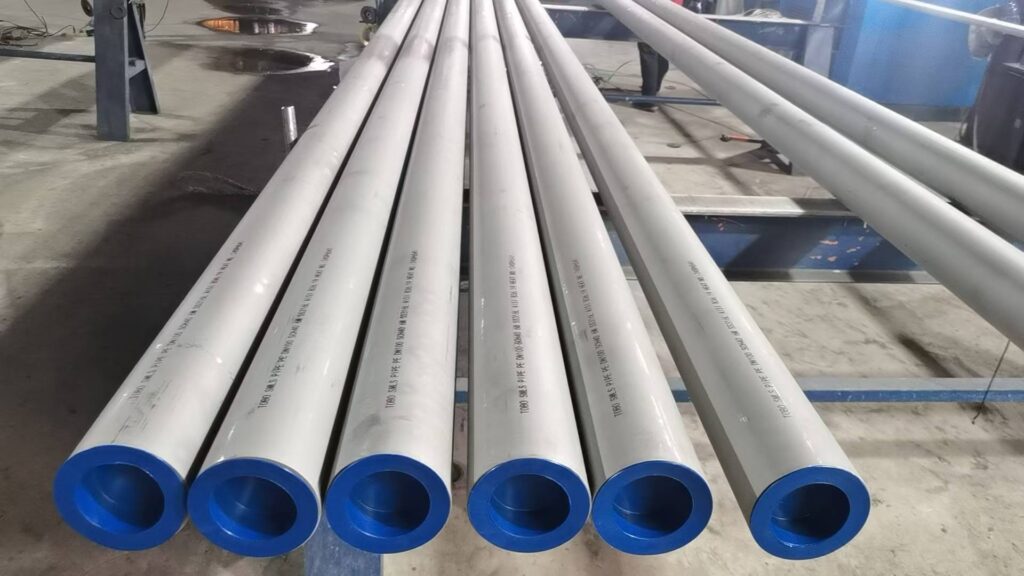

Stainless acid-resistant seamless steel pipe

According to the different contents of chromium, nickel and titanium, there are many varieties, including Cr13, 00Cr17Ni14Mo2, 1Cr18Ni12Mo2Ti, 1Cr18Ni9Ti, etc.

Among these steel grades, 1Cr18Ni9Ti is the most used, and it is often represented by the simplified material code 18-8 on the construction drawings.

The applicable temperature range is -196~700℃. In chemical production, it is used to transport various highly corrosive media, such as nitric acid, acetic acid and urea.

High pressure seamless steel pipe

Its manufacturing material is basically the same as the above-mentioned seamless steel pipe, but the pipe wall is thicker than the medium and low pressure seamless steel pipe, and the thickest pipe wall is 40mm.

For example, the specifications of high-pressure seamless steel pipes for fertilizer equipment are φ14×4 (mm) ~ 273×40 (mm), the length of a single pipe is 4 ~ 12m, the applicable pressure range is 10 ~ 32MPa, and the working temperature is -40 ~ 400℃.

In petrochemical plants, the above high-pressure seamless steel pipes are used to transport raw gas, hydrogen and nitrogen, synthesis gas, water vapor, high-pressure condensed water and other media.

Low temperature steel pipe

In the cold zone of imported engineering projects, the amount is large. The material grades are STPL-39 and STPL-46, and the working temperature can reach -105℃.

Low-temperature steel pipes are divided into seamless steel pipes and seamed steel pipes.

The nominal diameter of seamless low-temperature steel pipes is 15-400mm, and the wall thickness is the same as that of carbon steel pipes; the nominal diameter of seamed low-temperature steel pipes is 400-1100mm, the wall thickness is 6-10mm, and the standard length of a single pipe is 6m.

It is suitable for conveying various non-corrosive low-temperature medium pipelines. At present, there is no batch production of steel pipes corresponding to this standard in China.