Shock! Standard classification and structure of eccentric reducers

What are the classifications of eccentric reducers?

What is the standard system for eccentric reducers?

What are the structural characteristics of eccentric reducers?

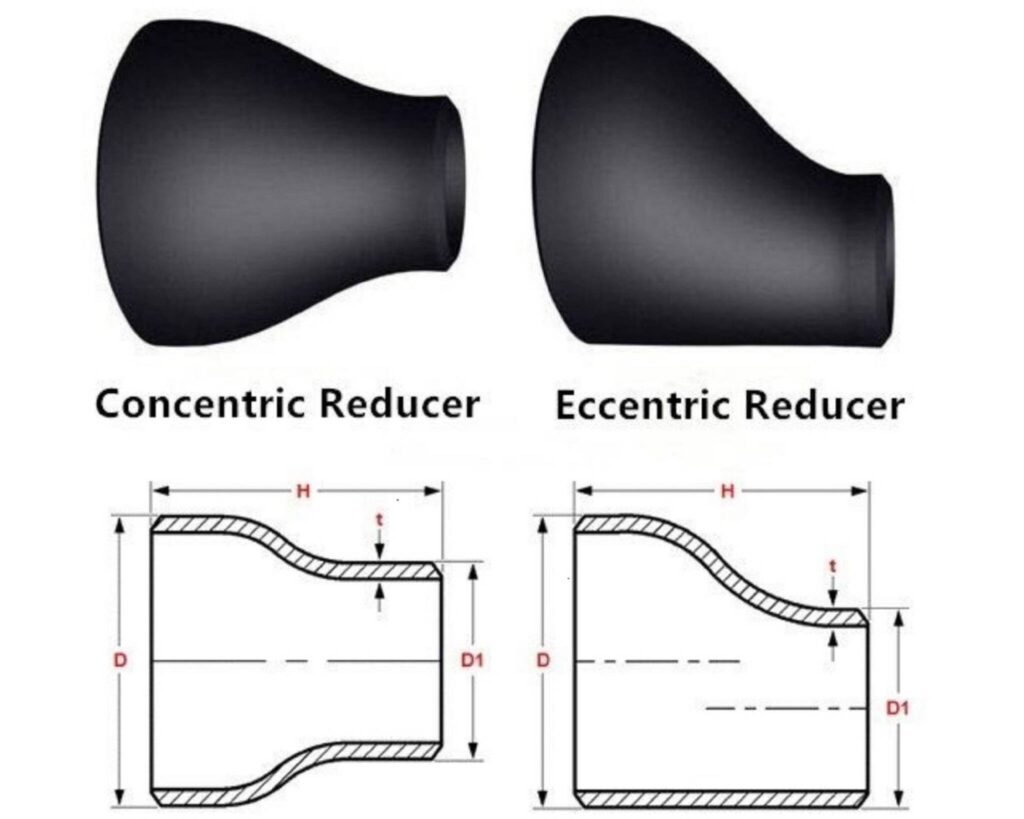

Eccentric reducer is a kind of pipe fitting used at the pipe diameter reduction.

The commonly used forming process is reduction pressing, diameter expansion pressing or reduction and expansion pressing. For certain specifications of reducers, stamping can also be used.

In addition to using steel pipes as raw materials to produce reducers, eccentric reducers can also be produced with steel plates using stamping forming processes for some specifications of reducers.

The shape of the punch used for drawing is designed with reference to the inner surface size of the reducer, and the die is used to draw the reducer. The blanked steel plate is stamped and stretched.

What are the classifications of eccentric reducers?

Divided according to material

Carbon Steel: ASTM/ASME A234 WPB, WPC

Alloy: ASTM/ASME A234 WP 1-WP 12-WP 11-WP 22-WP 5-WP 91-WP911, 15Mo3 15CrMoV, 35CrMoV

Stainless steel: ASTM/ASME A403 WP 304-304L-304H-304LN-304N

ASTM/ASME A403 WP 316-316L-316H-316LN-316N-316Ti

ASTM/ASME A403 WP 321-321H ASTM/ASME A403 WP 347-347H

Low temperature steel: ASTM/ASME A402 WPL3-WPL 6

High Performance Steel: ASTM/ASME A860 WPHY 42-46-52-60-65-70

Cast steel, alloy steel, stainless steel, copper, aluminum alloy, plastic, argon phosphate, PVC, PPR, RFPP (reinforced polypropylene), etc.

Divided according to production method

Divided into pushing, pressing, forging, casting, etc.

According to manufacturing standards

It can be divided into Chinese standards, electric standards, ship standards, chemical standards, water standards, American standards, German standards, Japanese standards, Russian standards, etc.

What is the standard system for eccentric reducers?

The European system pipe flange represented by Germany and the former Soviet Union

American system pipe flange standards, represented by ANSI B16.5 and ANSI B 16.47

British and French pipe flange standards, each country has two casing flange standards.

IOS7005-1 is a standard promulgated by the International Organization for Standardization in 1992.

This standard is actually a pipe flange standard that merges two series of pipe flanges from the United States and Germany.

What are the structural characteristics of eccentric reducers?

The characteristic of the core reducer is that its strength is significantly higher than that of carbon steel with the same carbon content, and it has good toughness and plasticity, as well as good weldability and corrosion resistance.

The roundness of the reducer should not be greater than 1% of the outer diameter of the corresponding end, and the allowable deviation is ±3mm.

The material of the reducer complies with SY/T5037, GB/T9711, GB/T8163, American standard ASTM A106/A53 GRB, API 5L, APT5CT, ASTM A105, ASTM A234, ASTM A106, DIN German standards and customer requirements.

Diameter reduction/diameter expansion forming

The reduction forming process of the reducer is to place a tube blank with the same diameter as the large end of the reducer into the forming mold, and by pressing the tube blank along the axial direction, the metal moves along the mold cavity and shrinks to form.

According to the size of the reducer, it is divided into one-time press forming or multiple press forming. The figure below is a schematic diagram of the reduction forming of a concentric reducer.

Diameter expansion forming is to use a tube blank smaller than the diameter of the large end of the reducer, and use an inner punch to expand the diameter along the inner diameter of the tube blank.

The diameter expansion process mainly solves the problem that the reducer with a larger diameter cannot be easily formed by diameter reduction.

Sometimes, the diameter expansion and diameter reduction methods are combined according to the material and product forming needs.

stamping forming

In addition to using steel pipes as raw materials to produce reducers, some specifications of reducers can also be produced using steel plates using the stamping forming process.

The shape of the punch used for drawing is designed with reference to the inner surface dimensions of the reducer, and the punch is used to punch and stretch the blanked steel plate into shape.

Why choose us?

At Metleader, there are several reasons why customers choose us: a large company team, strong warehousing capabilities, excellent teams and strict quality inspection processes.

This is our core competitiveness and an important guarantee for us to gain recognition in the global market. .

If you are interested in our products and want to know detailed quality inspection and price, please contact us and our engineers will contact you within 24 hours.