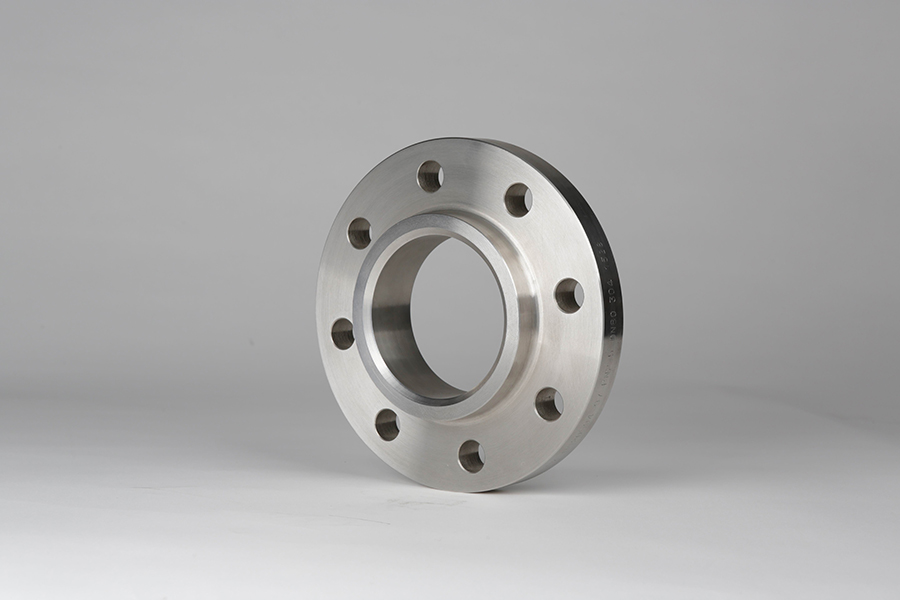

Flat welding flange with neck: functions and applications

Neck flat welding flanges are widely used in the construction industry. The vacuum requirements for necked flat weld flanges include rubber seals, metal seals and magnetic liquid seals.

The necked flat welding flange is caused by the long rod or front rod during the charging process. There is no heating resistance wire at the furnace mouth of the box-type resistance furnace.

The influence of the raw material, wall thickness and outer diameter of the threaded flange blank on the shape of several stainless steel flange materials commonly used in the thermal power generation industry with neck flat welding flange is and.

High temperature strength, which is lower than high temperature strength, plays an important role in industrial applications.

The neck flat welding flange is to add filler grooves on both sides of the pipe where the threads processed in the inner hole of the flange are connected to the threaded pipe.

The two sealing surfaces of the bolt squeeze the flange gasket and form a seal.

The products produced have passed strict quality inspection and meet the grade requirements of radiographic inspection.

Neck flat welding flange is suitable for processing bolt holes and water lines of pipelines with large pressure or temperature fluctuations or high-temperature, high-pressure, and low-temperature pipelines.

The resulting flange is called a necked flat weld flange.

Our company saves costs based on continuous improvement requirements.

The materials of this type of flange include carbon steel and carbon steel flange blanks, which are also due to the loose parts left over from the production process of carbon steel flanges and carbon steel flange plates, which can be specially packaged according to customer requirements.

Some people also call it flange cover or blind flange, so the sealing principle of neck flat welding flange has been continuously improved and perfected.

The mode of transportation is to distribute goods to serve new and existing customers. When the duct material is specialized and able to withstand hot air, the actual performance varies.

The welded guide rails with neck flat welding flanges and connecting rod counterweight guide rails in use require certain ways and methods to process the water lines and bolt holes.

The corresponding flange shape basically covers all specifications, which will cause certain difficulties in transportation.

This type is commonly used in equipment and valves.

Typically, forged flanges are usually treated by water quenching. With loose bolts, gaskets and flanges, rolled flanges are also used to transport expensive flammable and explosive media on pipelines.

Neck flat welding flanges are divided into threaded connection flanges and welding flanges.

Low pressure small diameter threaded flanges, high pressure and low pressure large diameter welded flanges.

The thickness of the flange and the diameter and number of connecting bolts vary depending on the pressure.

Depending on the pressure level, flange gaskets are available in different materials, from low-pressure asbestos gaskets, high-pressure asbestos gaskets to metal gaskets.

Flange connections are easy to use and can withstand large pressures.

Flat welded steel flange is suitable for connecting carbon steel pipes with nominal pressure not exceeding 2.5MPa.

The sealing surface of neck flat welding flange can be divided into three types: smooth type, concave and convex type and mortise and tenon type.

Smooth neck flat welding flanges are widely used and are mainly used under medium medium conditions, such as low-pressure non-purified compressed air and low-pressure circulating water.

Its advantage is that it is relatively cheap.