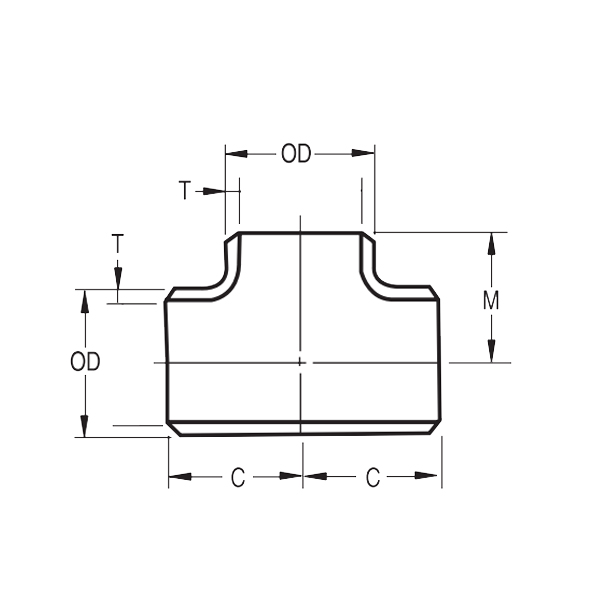

Let me show you what a tee pipe is

Tee is a kind of chemical pipe fitting with three openings, namely one inlet and two outlets; or two inlets and one outlet.

It has T shape and Y shape, with equal diameter pipe openings and reducing diameter pipe openings.

It is used for The convergence of three identical or different pipelines. The main function of the tee is to change the direction of the fluid.

Classification of tees

Divided by pipe diameter

The nozzle ends of equal diameter tees are all the same size;

The main pipe nozzle size of the reducing tee is the same, while the branch pipe nozzle size is smaller than the main pipe nozzle size.

Divided by process

Hydraulic bulging

The hydraulic bulging of the tee is a forming process that expands the branch pipe through axial compensation of the metal material.

The process is to use a special hydraulic press to inject liquid into the tube blank with the same diameter as the tee, and squeeze the tube blank through the synchronous centering movement of the two horizontal side cylinders of the hydraulic press.

The volume of the tube blank becomes smaller after being squeezed, and the inside of the tube blank becomes smaller. The pressure of the liquid increases as the volume of the tube becomes smaller.

When the pressure required for the expansion of the tee branch is reached, the metal material flows along the inner cavity of the mold under the dual action of the liquid pressure in the side cylinder and the tube and expands the branch.

The hydraulic bulging process of the tee can be formed in one step and the production efficiency is high; the wall thickness of the main pipe and shoulder of the tee has been increased.

Hot press forming

Tee hot press forming is to flatten the tube blank that is larger than the tee diameter to about the size of the tee diameter, and make a hole in the stretched branch pipe; the tube blank is heated, placed in the forming mold, and the tube blank is A die that stretches the branch pipe is installed inside; the tube blank is radially compressed under the action of pressure.

During the radial compression process, the metal flows in the direction of the branch pipe and forms a branch pipe under the stretching of the die.

The whole process is formed through the radial compression of the tube blank and the stretching process of the branch tube parts.

Different from the hydraulic bulging tee, the metal of the hot-pressed tee branch is compensated by the radial movement of the tube blank, so it is also called the radial compensation process.

Divided by material

Carbon steel, cast steel, alloy steel, stainless steel, copper, aluminum alloy, plastic, argon, PVC, etc.

Divided by production method

Top making, pressing, forging, casting, etc.

Divided by manufacturing standards

National standards, electrical standards, chemical standards, water standards, American standards, German standards, Japanese standards, Russian standards, etc., specifically as follows: GB/T12459-2017, ASME B16.9, SH3408, SH3409-96, SH3410-96, HG/ T21635,DL/T 695,SY/T 0510,DIN 2615.