45 Degree Elbow

What is 45 degree elbow?

45 degree elbow in the pipeline system is to change the direction of the pipe fittings. According to the different pipe diameter, It is divided into equal diameter and variable diameter two. In addition, the 90-degree elbow is also used in the pipe corner to connect, but the diameter of the pipe at both ends should be the same.

The connection modes with the pipe are: direct welding, flange connection, hot melt connection, electric melt connection, thread connection and socket connection, etc.

Classification of 45 degree elbows:

1. The type of elbow materials:

- Carbon steel: ASTM/ASME A234 WPB、20#、Q235.

- Stainless steel: ASTM/ASME A403 WP 304-304L-304H-304LN-304N;

ASTM/ASME A403 WP 316-316L-316H-316LN-316N-316Ti;

ASTM/ASME A403 WP 321-321H ASTM/ASME A403 WP 347-347H.

- Alloy steel: ASTM/ASME A234 WP 1-WP 12-WP 11-WP 22-WP 5-WP 91-WP911、15Mo3 15CrMoV、 35CrMoV.

- Low temperature steel: ASTM/ASME A402 WPL3-WPL 6, 16Mn, Q345.

- High performance steel: ASTM/ASME A860 WPHY 42-46-52-60-65-70.

2. Classification of elbow making methods:

- Push elbow

- Press elbow

- Forged elbow

- Casting elbow

3. Classification of manufacturing standard for elbows:

National standard, electrical standard, ship standard, chemical standard, water standard, American standard, German standard, Japanese standard, Russian standard and so on.

4. Classification of radius of curvature:

Long radius elbow

It refers to the outside diameter of the pipe whose radius of curvature is equal to 1.5 times, that is, R=1.5D.

Short radius elbow

It is one whose radius of curvature is equal to the outside diameter of the pipe, i.e. R=1.0D.

D is the diameter of the bend and R is the radius of curvature.

5. Classification of Pressure grade:

According to the pressure grade, including: Sch5s, Sch10s, Sch10, Sch20, Sch30, Sch40s, STD, Sch40, Sch60, Sch80s, XS, Sch80, SCH100, Sch120, Sch140, Sch160, XXS; The two most commonly used are STD and XS.

45 degree elbow detection diagram:

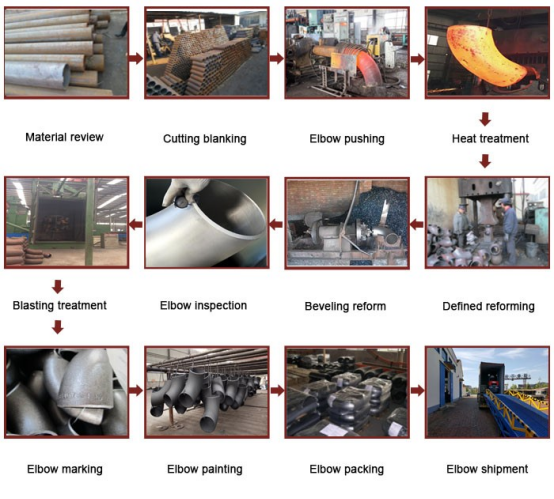

The production processing flow of elbows:

①Raw material acceptance inspection. The testing items include chemical composition, mechanical capacity and metallographic analysis.

② Cutting blanking. Correctly and strictly controlling cutting size and proportion.

③ Hot forming. In this step, put the raw material into the press to get the elbow blank.The temperature and speed of hot forming determine the quality of elbow blank.

④ Sizing. The shape of elbow blanks that got in hot forming process are not very good, so it is necessary to adjust the shape.

⑤ Heat treatment. The purpose of heat treatment is to eliminate the stress inside of elbow so that the density is more evenly.

⑥ Short blasting. The purpose of short blasting is to remove the rust on the elbow.

⑦ Bevel end machining. The angle of bevel end is different for different standard elbow. Strictly controlling the machining process to make sure the angle is qualified.

⑧ Coating. Generally the coating is black painting, vanish and anti-rust oil. No matter which type the surface should be smoothly.

Why choose us to buy elbows?

Metleader has been exporting products with big quantity to many countries and areas. Our company have been passed several certificates including ISO9001: 2008, ISO14001, OHSAS18001, CE certificate, one member of supplier system of Sinopec, and CNPC.

Our company mainly produces carbon steel, alloy steel, and stainless steel pipe fittings, with professional equipment, and the quality is strictly in accordance with standards. Welcome your inquiry at any time salesmanager@metleader.com.