Everything You Need to Know About Elbow Angles

Table of Contents

Elbow is a kind of pipe fitting in the pipeline system, which is mainly used to change the direction of the pipeline or connect pipes of different diameters, making the pipeline layout more flexible and compact. Elbows are usually described by factors such as angle, bending radius, and material.

Elbows have certain bending performance and load-bearing capacity, and also play a role in reducing flow resistance, pressure drop, flow noise, and vibration.

How to use elbows correctly

Position

When arranging elbows, it is necessary to avoid connecting elbows in series as much as possible to avoid making the piping system unusually complicated. At the same time, the position of the elbows should be arranged according to the design load of the pipeline, the pressure it bears, the medium characteristics and other conditions.

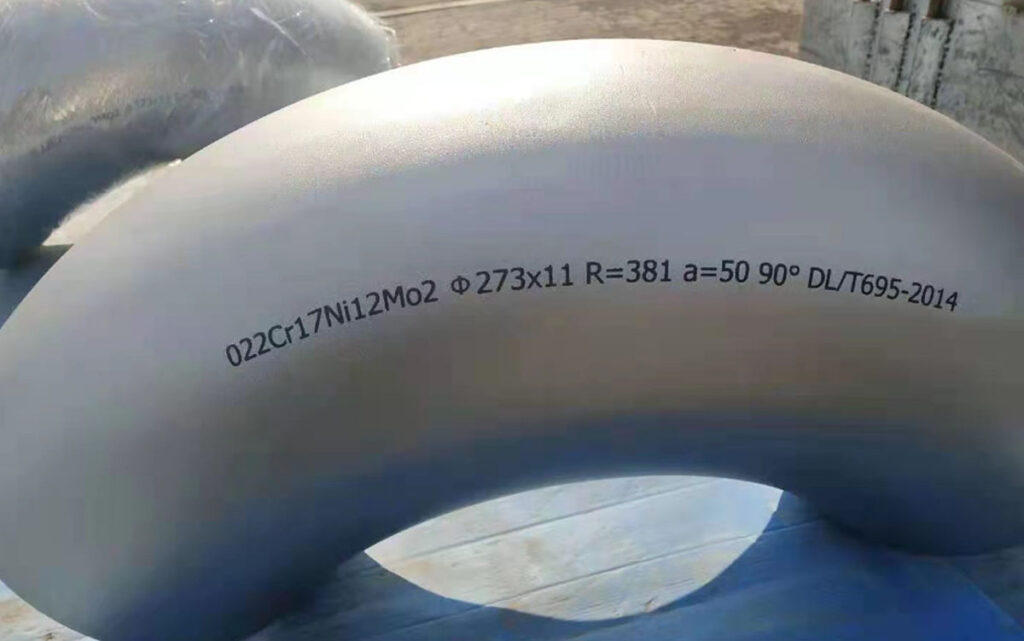

Angle

The angle of the elbow is generally 45 degrees, 90 degrees, 180 degrees, etc. The larger the angle, the greater the resistance to the fluid passing through. When choosing the elbow angle, it should be determined according to actual needs to avoid excessive resistance and pressure loss.

Bending radius

The bending radius of the elbow refers to the radius of curvature, which is generally greater than or equal to three times the diameter of the pipe. The smaller the bending radius of the elbow, the greater the resistance and pressure loss in the pipeline. In actual use, elbows with larger radius should be selected as much as possible.

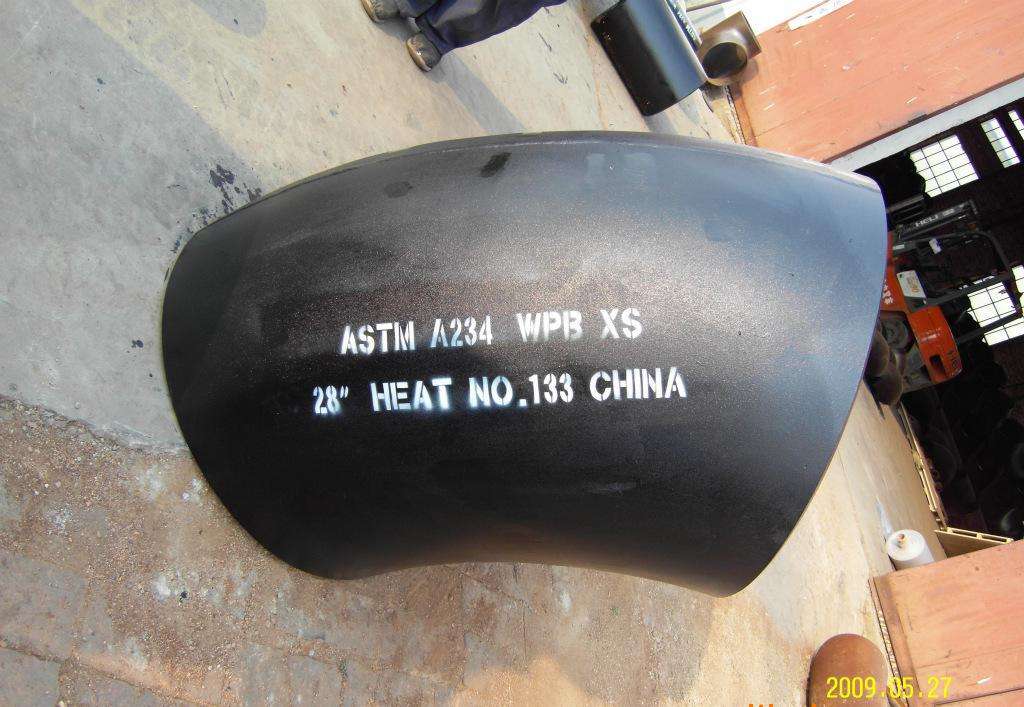

Material

The material of the elbow should be the same as that of the pipe or have good compatibility, and it is required to have good toughness and corrosion resistance. When selecting materials, the working temperature, pressure and medium of the elbow should also be considered to avoid damage or leakage.

Elbow angle classification

90 degree elbow

The 90-degree elbow is one of the most common elbows, with an angle of 90 degrees. In the piping system, the 90-degree elbow is often used to change the direction of the pipeline so that the pipeline extends in different directions. In addition, in the manufacturing industry, the 90-degree elbow is also often used to change the flow direction of the fluid medium.

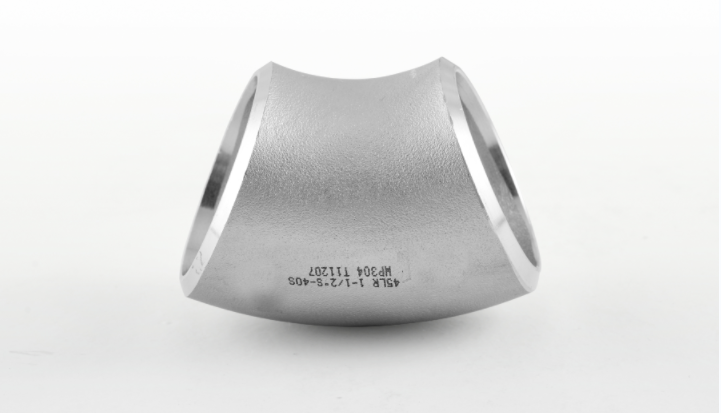

45 degree elbow

The angle of the 45-degree elbow is 45 degrees, and it is usually used for slight bends at certain angles in the piping system to make the pipeline more compact. In addition, the 45-degree elbow can also be used to change the direction of fluid flow so that the fluid is not subject to excessive resistance.

30 degree elbow

The angle of the 30-degree elbow is 30 degrees, and it is usually used in piping systems where the direction of fluid flow needs to be forced to change. 30-degree elbows are not commonly used in construction, but they are very useful in specific situations, such as: you need to make the piping system bypass certain obstacles.

60 degree elbow

The 60-degree elbow has an angle of 60 degrees and is usually used in situations where the flow of fluid in a piping system needs to change direction. Compared to a 30-degree elbow, a 60-degree elbow has a greater curvature and can better bypass obstacles in a piping system.

180 degree elbow

A 180-degree elbow is an elbow that completely twists the pipe, with an angle of 180 degrees. Although 180-degree elbows can be used to change the direction of the pipe in some cases, they should generally be avoided when designing and constructing piping systems.

Common elbow types

According to different pipe connection requirements, elbows can be divided into different types. Common elbow types include:

- Welded elbow: needs to be welded with the pipe, widely used;

- Pneumatic elbow: changes the direction of the pipe by compressed air, hydraulic pressure, etc.;

- Insert elbow: can be directly inserted into the pipe, and the elbow can be replaced without disassembling the pipe;

- Expanding elbow: one end of the pipe is expanded like a whistle, so that the inner diameter of the pipe is not affected, suitable for occasions with pressure and flow requirements;

- Variable diameter elbow: can connect large-diameter pipes to small-diameter pipes, suitable for some special occasions.

Precautions

When choosing an elbow, you need to choose the appropriate angle and elbow type according to the actual use occasion. In addition, you need to pay attention to the following points:

- The curvature radius of the elbow cannot be too small, otherwise it will affect the flow and pressure parameters of the pipeline;

- Do not use too many elbows in the same pipeline, otherwise it will increase resistance and energy consumption;

- The manufacturing material of the elbow needs to be the same or similar to the material of the pipeline to avoid corrosion problems and leakage hazards caused by different materials.

Summary

Elbows play an important role in pipeline engineering.

Reasonable selection and correct use of elbows can ensure the normal operation and service life of the pipeline.

When selecting elbows, factors such as the fluid medium, pipe diameter, and flow rate of the pipeline need to be considered.

Only by selecting elbows with appropriate angles can the stable operation of the entire pipeline system be ensured.