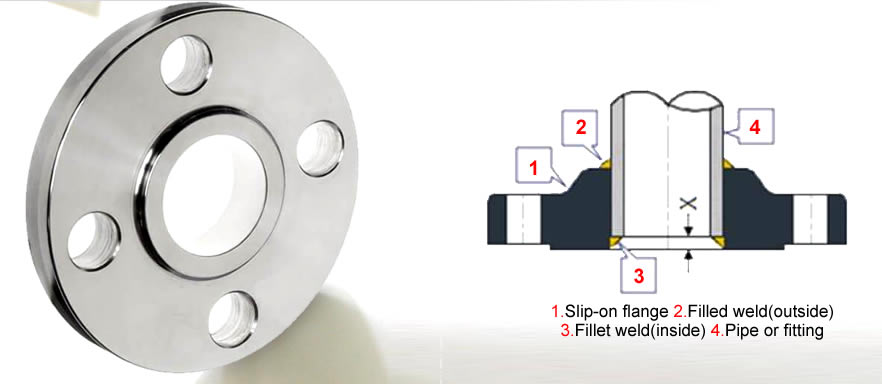

Stainless steel slip on flange

Stainless steel slip on flange

What is stainless steel slip on flange?

Stainless steel slip on flange is a type of flange that is welded directly to equipment or pipes through a fillet weld, simple structure and convenient processing. It is the most commonly used flange type with low cost and short production cycle, and is widely used in various fluid pipelines.

There are a variety of sealing surface types of flange, generally used are convex surface (RF), concave surface (FM), convex surface (M), tenon surface (T), groove surface (G), full plane (FF), ring joint surface (RJ).

characteristic:

| Simple and easy to handle | It has simple structure and convenient installation. The connection can be completed by tightening the flange with pressure by installing bolts and washers, and maintenance is relatively easy. |

| Suitable for low pressure systems | It is widely used in low pressure systems, such as cooling water, sewage, compressed air and other piping systems. |

| Simple process | The processing process and installation steps of the slip on flange are relatively simple, so the production cost is relatively low. |

In short, the structure of slip on flange is simple, fast installation, relatively low cost. It suitable for low pressure, some non-harsh environment of the pipeline system and equipment.

Advantages and disadvantages of stainless steel slip on flange:

Advantages:

- Good sealing performance

- Easy installation

- Low cost

- Broad application

When the flange is deformed, no additional torque will be produced to the container or pipeline.

Disadvantages:

Low strength of loose ring, low pressure, can not be used for high-pressure pipe network.

What is the function of the slip on flange?

The slip on flange is a movable flange piece, which is generally matched with the water supply and drainage fittings.

When the manufacturer leaves the factory, there is a flange at both ends of the expansion joint, which is directly connected with the pipeline and equipment in the project by bolts. It is usually used on pipes, so that the loose bolt can rotate the pipes on both sides and tighten them. It can be more convenient to disassemble and assemble the pipe.

Note: If you have any purchase plan , please feel free to contact us. salesmanager@metleader.com