Stainless Elbow Fitting

What is a stainless elbow fitting?

In piping and plumbing systems, stainless elbow fitting is a kind of pipe fitting that connects two lengths of pipe to change the direction. There are common angles elbow having 45° , 90° and 180°, abnormal Angle elbow such as 60°. 304/304L and 316/316L stainless steel elbows can withstand high pressure and resist corrosion, duplex steels and nickel alloys are available.

Stainless steel is usually increased on the basis of carbon steel with a high proportion of Cr, Ni and other alloys, the proportion of content can reach more than 20%. It has higher strength and corrosion-resistances than carbon steel elbow.

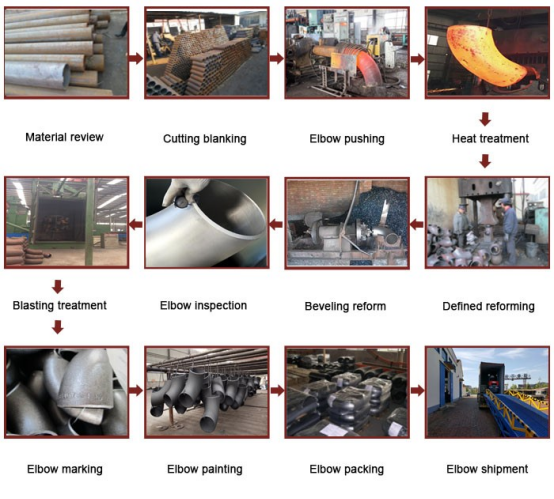

The production process of stainless elbow elbow:

The production process of elbows includes push system and pressing two kinds. The pushing process is the small diameter steel pipe to push large diameter elbow, and the wall is seriously reduced; The pressing process is the same caliber pressing, which is suitable for thick wall products, and will also produce wall reduction but not as serious as the pushing process.

The temperature of elbow pushing is related to the wall thickness of the material. The thicker the wall thickness, the higher the temperature of the pushing.

Elbow production process:

Knowledge of elbow manufacturing process:

I believe you are curious about elbows manufacturing production, let’s understand the knowledge process of elbow manufacturing production.

- The elbow is usually connected directly to the pipe or flange. In order to have a strong connection welding quality, when the elbow production will leave a groove at the end of the elbow. The groove is set at a reasonable angle so as not to make the elbow too thin or too thick. In this way, the stiffness of the elbow can not be damaged in the process of connection.

- Elbows in the manufacturing process need to be surface treatment. It needs to paint or sandblaste on the surface of the elbow. In this way, the elbow can be preserved and transported.

- Elbows in the production of the general use of these methods: stamping method, roll method, cold bending method, push method, and so on. Taking cold pressing as an example, this production method is directly use mechanical bending pipes to make elbows with low cost and wide application range. However, it also has certain disadvantages, such as the metal structure of the elbow itself will be damaged in the process of cold bending, which will make the elbow become weak and reduce the service life of the elbow. Therefore, in some stringent pipeline environments, should try not to use this elbow.

Why choose us to buy elbows?

First of all, Metleader is a manufacturer and supplier of steel pipes, pipe fittings and flanges in the world.

Secondly, Our company have been passed several certificates including ISO9001: 2008, ISO14001, OHSAS18001, CE certificate, one member of supplier system of Sinopec, and CNPC.

Thirdly, We have the production of forged carbon steel, stainless steel pipe fittings professional equipment. Our quality is strictly in accordance with the standards to implement, welcome you to the field visit.

Above all, we will provide the best service to customes. Welcome your inquiry timely salesmanager@metleader.com.