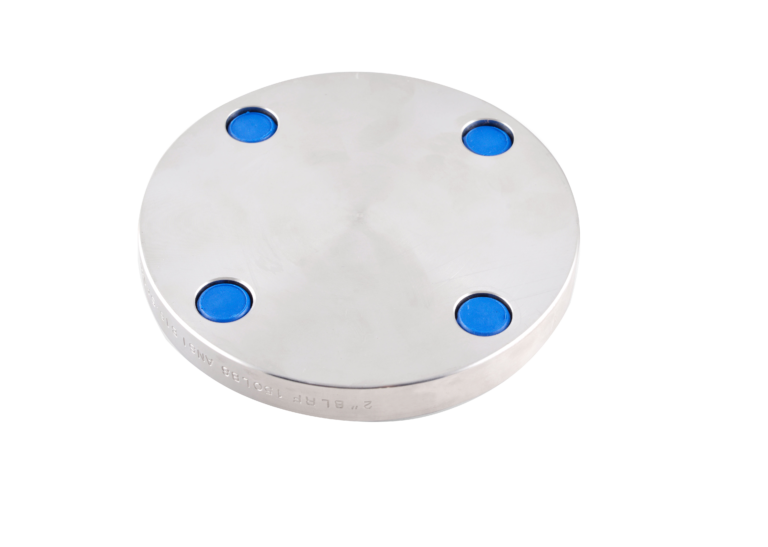

Socket welding flange

Socket welding flange

What is socket welding flange?

Socket welding flange is typically used on smaller sizes of high pressure pipes.

It refers to the pipe end inserted into the flange ring ladder, welded at the pipe end and outside the flange. The flange has good rigidity, small welding deformation and good sealing that can be used for the occasions of 1.0~10.0MPa pressure.

Flange connection:

Socket weld flange connection is an important connection mode for pipeline construction, which is the two pipes, pipe fittings or appliance materials, respectively fixed on a flange plate, between the two flanges, plus flange pad, fastening together with screws, to complete the connection.

Socket welding flanges are divided into threaded connection flanges and welded flanges. Low pressure small diameter wire flange, high pressure and low pressure large diameter are welded flange, different pressure flange thickness and connecting screw diameter and number are different. Flange connection is easy to use and can bear greater pressure. It is widely used in industrial pipes.

brief introduction:

1. Form of sealing surface

Surface (RF), concave-convex surface (MFM), mortise surface (TG), ring joint surface (RJ).

2. Range of application

Boiler pressure vessels, petroleum, chemical, shipbuilding, pharmaceutical, metallurgy, machinery, stamping elbow food and other industries. It is usually used in pipelines with PN≤10.0MPa and DN≤40.

3. Manufacturer’s standard

ANSI B16.5、HG20619-1997、GB/T9117.1-2000—GB/T9117.4-200、HG20597-1997.

4. Connection type

Flange nut, bolted connection.

5. Manufacturing technique

Professional overall forging, forging manufacturing, etc.

6. Method of processing

High precision CNC lathe turning, ordinary lathe finishing, argon arc welding and other processing.

Our scope of supply:

| Standard | Carbon steel ASTM A105, ASTM A350 LF1/2, ASTM A181 Alloy steel ASTM A182 F5, F9, F11, F22, F91 Stainless steel ASTM A182 F304/L, F316/L |

| Outer Diameters | 1/2 inch to 24 inch, up to 2500# |

| Special made | 24” to 60”, up to 900# |

| Wall Thickness: | Schedule 40 to 160 |

| Pressure Ratings | Class 150 to Class 2500. |

| Face Type | RF, RTJ |