ASTM A234 WPB vs A105: Key Differences in Carbon Steel Fitting Performance

Table of contents

Preface

What Are ASTM A234 WPB and A105?

Chemical Composition: What’s Inside?

Strength and Durability Comparison

When to Use WPB vs A105

Common Mistakes to Avoid

FAQ

Summarize

Preface

Choosing the wrong type of carbon steel fittings can lead to leaks, pipe ruptures, and even accidents. This mistake happens because they don’t understand the difference between ASTM A234 WPB and A105.

Both materials are common in pipes and valves, but they work best in different situations.

Today we introduce the differences between them and hope to provide you with some help.

What Are ASTM A234 WPB and A105?

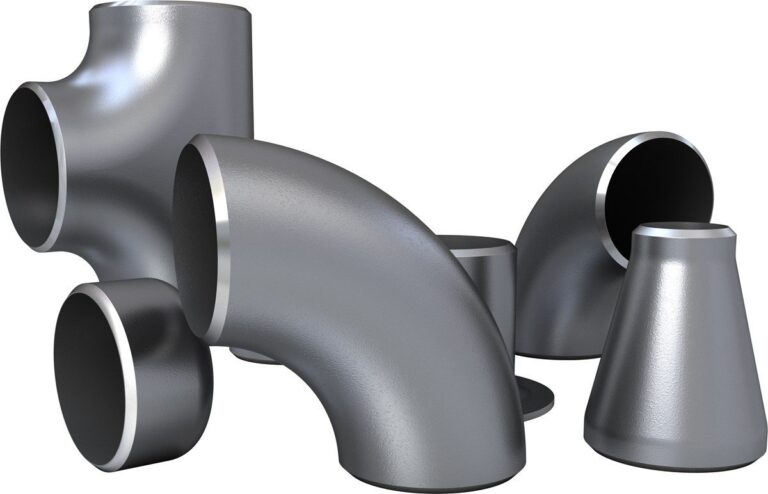

- ASTM A234 WPB:

- Used for welded fittings like elbows and tees.

- Works in moderate heat (up to 425°C).

- Matches pipes like ASTM A106.

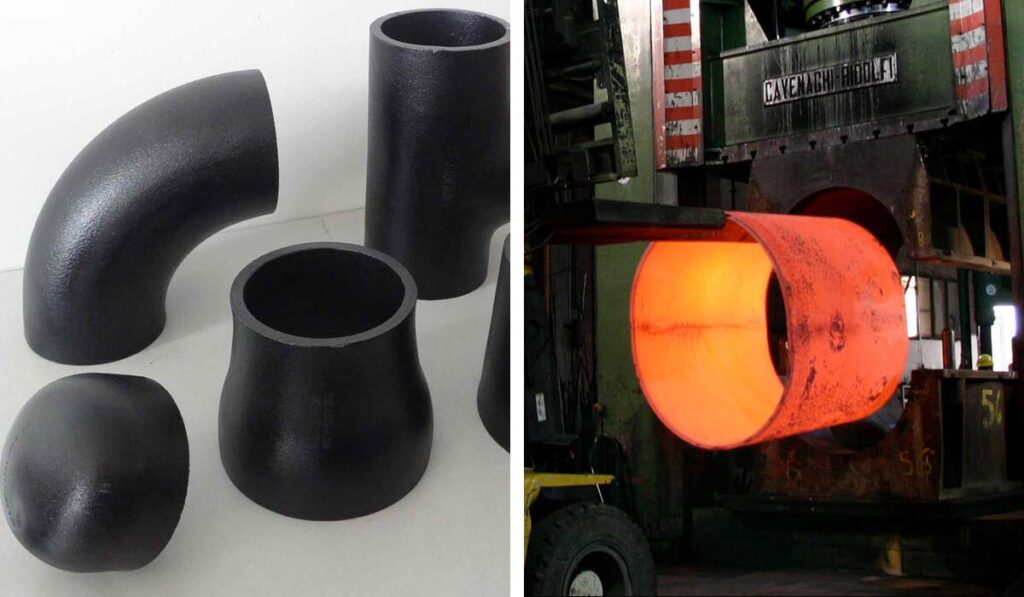

- ASTM A105:

- Used for forged parts like flanges and socket welds.

- Handles higher pressure but lower heat (up to 370°C).

- Common in valves and pumps.

Chemical Composition: What’s Inside?

- A234 WPB:

- Carbon (C): ≤0.30%

- Manganese (Mn): 0.29-1.06%

- Cheaper but slightly weaker.

- A105:

- Carbon (C): ≤0.35%

- Manganese (Mn): 0.60-1.05%

- More manganese makes it stronger for heavy loads.

Strength and Durability Comparison

| Property | A234 WPB | A105 |

| Tensile Strength | 415-585 MPa | 485-655 MPa |

| Yield Strength | ≥240 MPa | ≥250 MPa |

| Hardness | ≤197 HB | ≤187 HB |

When to Use WPB vs A105

- Choose WPB If:

- You need welded fittings (elbows, tees).

- The system runs below 3,000 PSI.

- Budget is tight.

- Choose A105 If:

- You need forged parts (flanges, valves).

- Pressure exceeds 3,000 PSI.

- Long-term reliability is critical.

Common Mistakes to Avoid

- Using WPB for Flanges:

- WPB isn’t strong enough for bolted connections. Always use A105 for flanges.

- Mixing Materials:

- Don’t pair A105 flanges with WPB pipes unless tested. Mismatched parts can leak.

- Ignoring Temperature:

- WPB handles heat better. For systems above 370°C, avoid A105.

FAQ

Q1: Can I replace A105 with WPB to save money?

A105 is stronger. Using WPB in high-pressure systems risks leaks or breaks.

Q2: Does A105 rust faster than WPB?

Both resist rust similarly. For corrosive environments, add coatings like galvanizing.

Q3: Which is better for water pipes?

WPB is fine for low-pressure water systems. Save A105 for oil, gas, or steam.

Summarize

Choosing between ASTM A234 WPB and A105 depends on the pressure, temperature and budget of your project.

Metleader is committed to providing a complete solution for your project, if you need help, please contact us for personalized advice.