API 5L Large Diameter Spiral Welded Steel Pipe

What is large diameter spiral welded steel pipe?

API 5L large diameter spiral welded steel pipe (double-sided submerged arc welded pipe) is a steel pipe with strip coil plate as raw material, extruded at constant temperature and welded by automatic double-wire double-sided submerged arc welding process.

Application:

- 1) General service for industries ( petroleum, chemical, aviation, etc.)

- 2) Fluid, gas and oil transport.

- 3) Press and heat transmission.

- 4) City construction, etc.

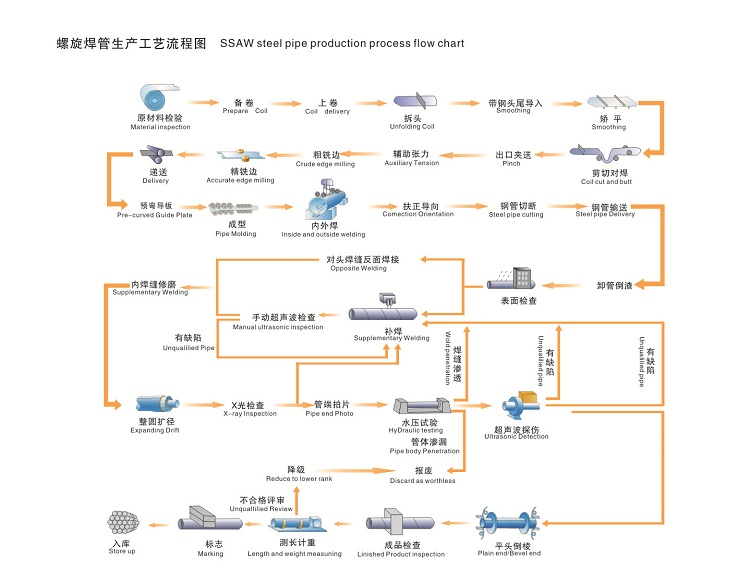

The main production process flow chart of spiral welded steel pipe:

The spiral steel pipe feeds the strip into the welding pipe set. After the strip is rolled by several rolls, it is gradually rolled up to form a round pipe blank with open gap. And the two ends of the weld are flush.

Quality assurance

On the basis of the requirements of the spiral welded steel pipe production standard, the main inspection items for spiral welded steel pipe include:

- 1) Dimensions: Outer diameter, wall thickness, ellipticity, curvature, vertical of pipe end.

- 2) Length and appearance quality: weld reinforcement, wrong edge, steel pipe surface, delamination, inclusions, weld defect judgment.

- 3) Chemical composition analysis.

- 4) Tensile test of welded joint.

- 5) Hydrostatic pressure test.

- 6) Metallgraphic examination.

- 7) Acid etching inspection.

- 8) Non-destructive testing.

- 9) Mechanical performmance tasting.

product display:

Advantages and disadvantages of spiral welded pipe:

Advantages:

- 1) Steel pipes of different diameters can be produced with strips of the same width.

- 2) Under the same pressure conditions, the stress of the spiral weld is less than that of the straight seam.

- 3) Accurate size.

- 4) Continuous production.

- 5) Compared with the straight seam welded pipe, its operation is flexible and the replacement variety is convenient to adjust.

- 6) Easy to realize mechanization and automation.

- 7) Light weight of equipment.

- 8) Less initial investment.

disadvantages:

- 1) Due to the use of coil steel as raw materials, there will be a certain crescent crescent.

- 2) The welding point is in the elastic strip edge area, so it is difficult to align the welding torch and affect the welding quality.