API 5L PSL1 VS PSL2

The main differences between API 5L PSL1 seamless pipe and PSL2 are as follows:

Inspection requirements:

PSL2 is stricter than PSL1 in terms of chemical composition, tensile properties, impact energy, non-destructive testing and other indicators.

PSL1 does not require impact performance and non-destructive testing, while PSL2 requires full-size 0℃ impact energy tests for all steel grades except X80 steel grade, and requires non-destructive testing of each steel grade.

Product specification level:

The product specification level of PSL2 is higher than that of PSL1, which means that PSL2 steel pipes have higher requirements in terms of quality grade, chemical composition and mechanical properties.

Applicable scenarios:

Since PSL2 has more stringent requirements, PSL2 seamless steel pipes are usually selected in scenarios where higher performance is required, such as places with harsh environments or high working pressure.

In some places where performance requirements are not so strict, PSL1 seamless steel pipes may be selected.

When choosing API 5L PSL1 seamless steel pipe vs PSL2, you need to consider the following factors:

Project requirements:

First, you need to consider your project requirements. If your project needs to withstand higher pressures, temperatures, or corrosive environments, then PSL2 may be a better choice.

Cost considerations:

Since PSL2 has more stringent requirements, its production cost is usually higher than PSL1. When choosing, you need to consider cost factors while meeting the project requirements.

Supplier capabilities:

Different suppliers may have different production capabilities and technical levels, so when choosing steel pipes, you also need to consider the supplier’s capabilities to ensure that they can provide high-quality steel pipes according to your requirements.

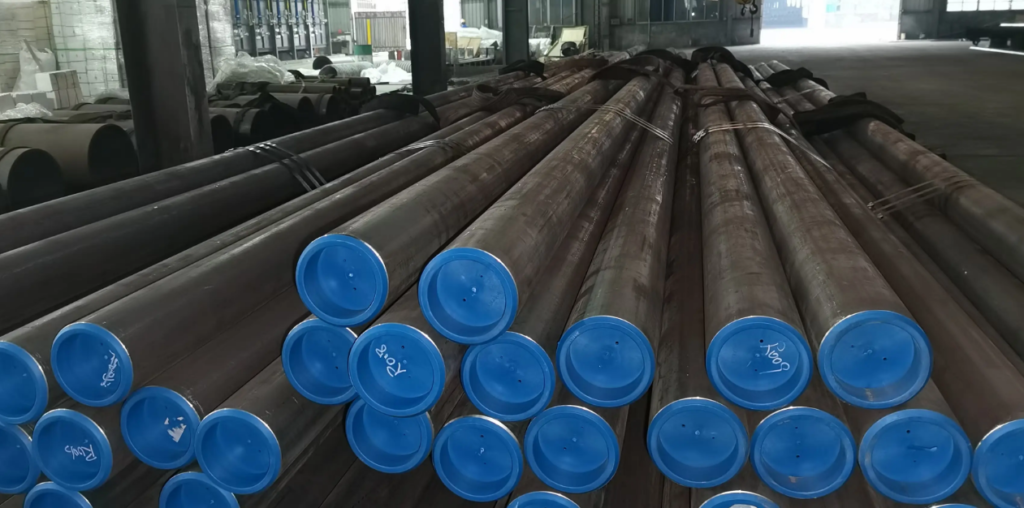

API 5L PSL1 seamless steel pipe is widely used in many engineering fields, mainly including the following fields:

Oil and gas transportation:

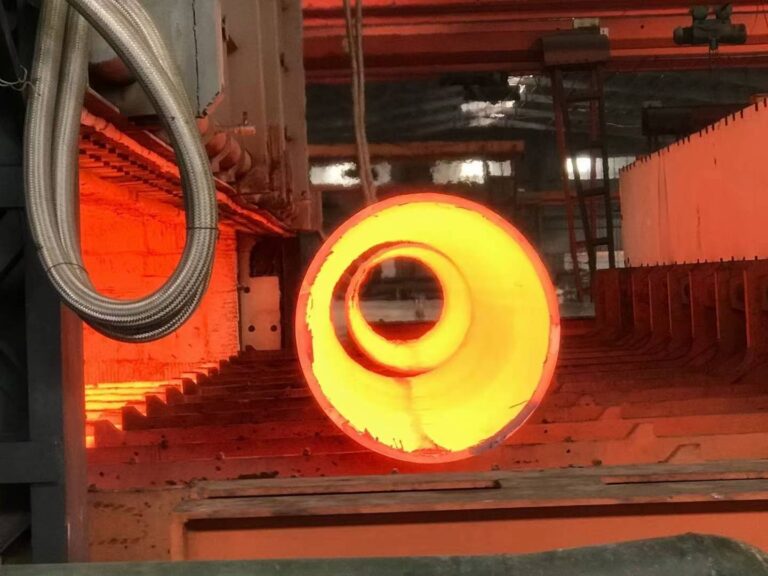

This is the main application area of API 5L PSL1 seamless steel pipe.

Due to its high strength, corrosion resistance and good mechanical properties, this steel pipe is widely used in oil and gas transportation pipelines.

In these applications, the steel pipe needs to withstand high pressure, high temperature and corrosive environment, and API 5L PSL1 seamless steel pipe can meet these requirements.

Chemical and pharmaceutical industries:

These industries need to deal with various corrosive media, so the corrosion resistance of steel pipes is high.

API 5L PSL1 seamless steel pipe has good corrosion resistance after special treatment, so it is widely used in equipment and pipelines in the chemical and pharmaceutical industries.

Water conservancy projects:

API 5L PSL1 seamless steel pipe is also commonly used in water pipelines in water conservancy projects, such as the construction of large reservoirs, hydropower stations and other projects.

In these applications, the steel pipe needs to withstand the impact and pressure of the water flow, and also needs to have good sealing performance.

Other fields:

In addition, API 5L PSL1 seamless steel pipe can also be used in other fields, such as construction, shipbuilding, machinery manufacturing, etc.

In these fields, steel pipes are mainly used to bear structural loads and transmit fluid media.