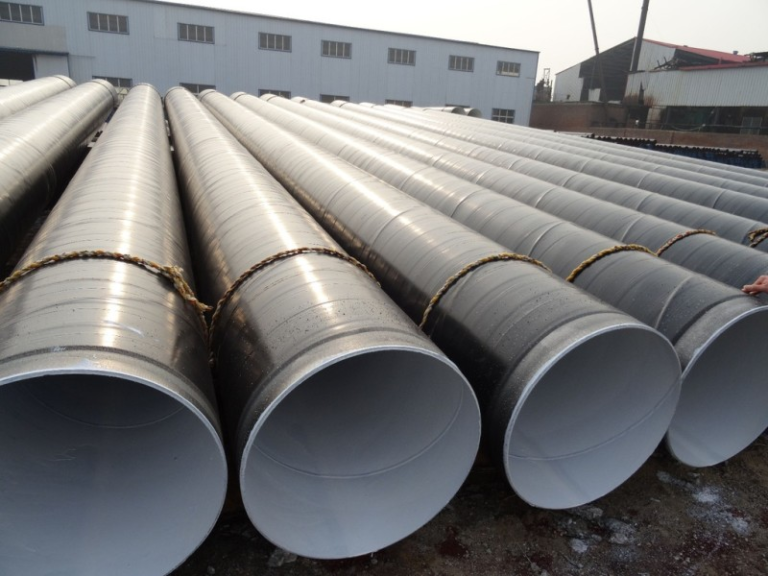

High quality carbon seamless steel pipe

High quality carbon seamless steel pipe

What is carbon seamless steel pipe?

Carbon seamless steel pipe is made by perforating ingot or solid pipe billet and then hot rolling, cold rolling or cold drawing. Carbon seamless steel pipe occupies an important position in Chinese steel pipe industry.

Carbon seamless steel pipes transport water, oil, gas or other chemical fluids. The performance of seamless steel pipe is very good, and it has a wide range of applications, and has good corrosion resistance, practicability is indeed guaranteed, and the service life is also very long. Moreover, many construction parties need to purchase steel pipes in large quantities.

When it comes to pipeline construction, carbon steel seamless pipes are often the most economical choice. They are generally less expensive and require less maintenance than other types of plumbing. This pipe is usually made of steel, so it is flexible. They also come in different sizes, so you can find one size that meets your requirements.

What is high temperature carbon steel pipe?

Carbon steel is an alloy with carbon and iron, with carbon content up to 2.1% by weight. The increase in the carbon percentage will raise steel’s hardness and strength, but it will be less ductile. High temperature piping refers to piping systems designed for high temperatures, especially at temperatures exceeding 800°F(425°C).

The steel shall have sufficient creep strength and maintain good heat resistance, corrosion resistance, metallurgical stability, oxidation resistance, stress rupture resistance and surface stability, not affected by combustion gases and chemicals.

High quality Carbon Seamless Steel Pipe Specification:

| Material | GR.B,ST52, ST35, ST42, ST45,X42, X46, X52, X56, X60, X65, X70,SS304 |

| Standard | API5L , ASTM A106 Gr.B, ASTM A53 Gr.B,ANSI A210-1996, ANSI B36.10M-2004 , ASTM A1020-2002,ASTM A179-1990 ,BS 3059-2,DIN 17175 ,DIN 1630 ,DIN 2448 |

| Certificates | ISO 9001:2008, SGS, |

| Dimensional specification | ANSI/ASME B36.19M, ANSI/ASME B36.10M |

| Size | 1/2 inch to 12 inch, 14 inch, 16 inch, 18 inch, 20 inch, and 24 inch for seamless. |

| Length Range | 20 FT (6 meter), 40FT (12 meter)or customized |

| Surface Coatings | Natural, Black painting, 3PP, 3PE and FBE, Cladding and Lined etc. |

| Shapes | Round, Rectangle |

| Manufacturing Techniques | Seamless / Rectangular / round |

| Schedule Thickness Range | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| End Types | Plain End, Beveled End, Threaded One End, TBE (Threaded Both Ends) |

| Delivery Condition | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Inspection | hydraulic testing, eddy current, infrared test |

| Packaging | Loose package; Packaged in bundles(2Ton Max); bundled pipes with two slings at the both end for easy loading and discharging; |

Application of carbon seamless steel pipe:

Carbon steel seamless pipes are extensively applied in the nuclear device, gas conveyance, petrochemical, shipbuilding and boiler industries, with characteristics of high corrosion resistance combined with suitable mechanical properties.

– Nuclear device

– Gas conveyance

– Petrochemical industries

– Shipbuilding and boiler industries

Why choose carbon seamless steel pipes?

Carbon seamless steel pipes are currently one of the most popular choice for people looking for durable, high quality pipes that will stand the test of time. Carbon seamless steel pipes are known to withstand extreme pressure, corrosion and rust. One of the advantages of using these special pipes is their durability, as they do not wear out over time as steel pipes do.