Carbon steel 90 degree pipe elbow

Carbon steel 90 degree pipe elbow

What is carbon steel 90 degree elbow?

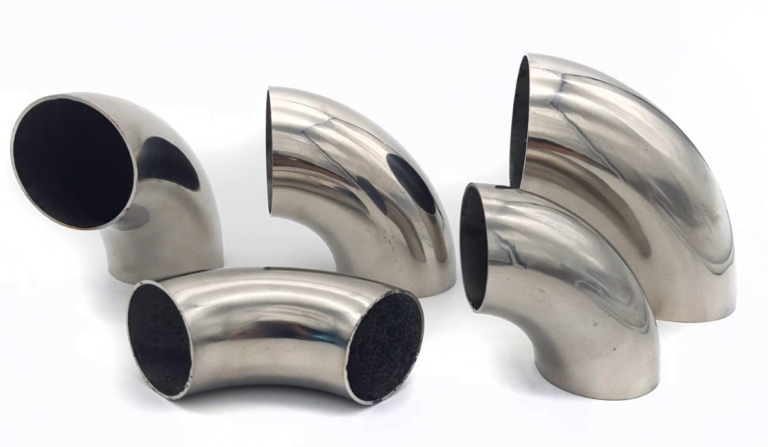

Carbon steel 90 degree pipe elbow is a metal pipe fitting that changes the direction of the pipes. Except for 90 degree elbow, there are two other types 45 degree and 180 degree. As the connection of carbon steel elbow is butt weld, it can be also called butt weld elbow.

The types of carbon steel pipe elbow.

There are several classification method for pipe elbow, mainly including these ways as below.

1.According to degree, carbon steel elbow can be divided to:45 degree elbow, 90 degree elbow and 180 degree elbow.

2.According to the radius of curvature, it has long radius elbow and short radius elbow, also can be called 1.5D and 1D, “D” means diameter of elbows.

3.According to pressure to divide, it is about 17 types which is same as the American standard pipes refer to Sch5s、Sch10s、Sch10、Sch20、Sch30、Sch40s、STD、Sch40、Sch60、Sch80s、XS;Sch80、Sch100、Sch120、Sch140、Sch160、and XXS. STD and XS are the most popular.

4.According to the standard, there are ASME, DIN, EN, JIS, and GOST.

The material of carbon steel elbow.

The material of carbon steel elbow generally including ASTM A234 WPB, WPC, St37, A105 etc.

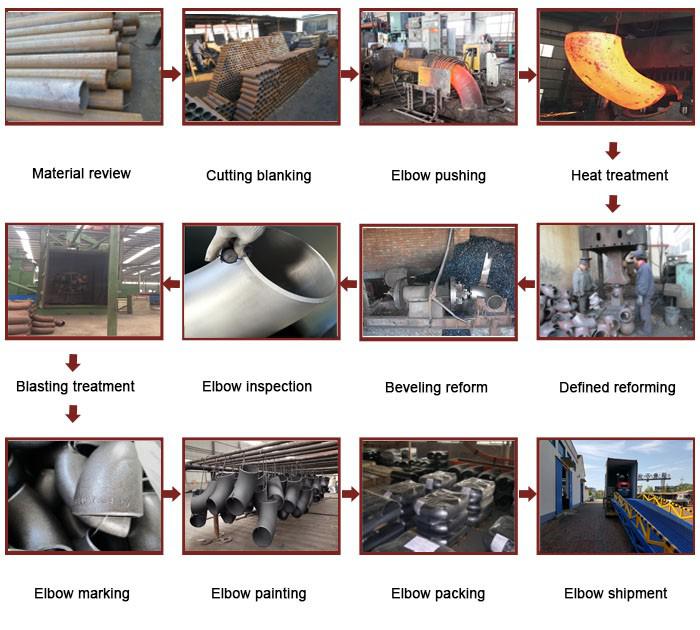

The production processing of carbon steel 90 degree pipe elbow.

Elbow is the largest proportion of all pipe fittings, 80% elbows used in the piping system . Generally, different forming processes are selected for different materials or wall thickness elbow. The seamless elbow forming process commonly used by manufacturers includes hot pushing, stamping and extrusion.

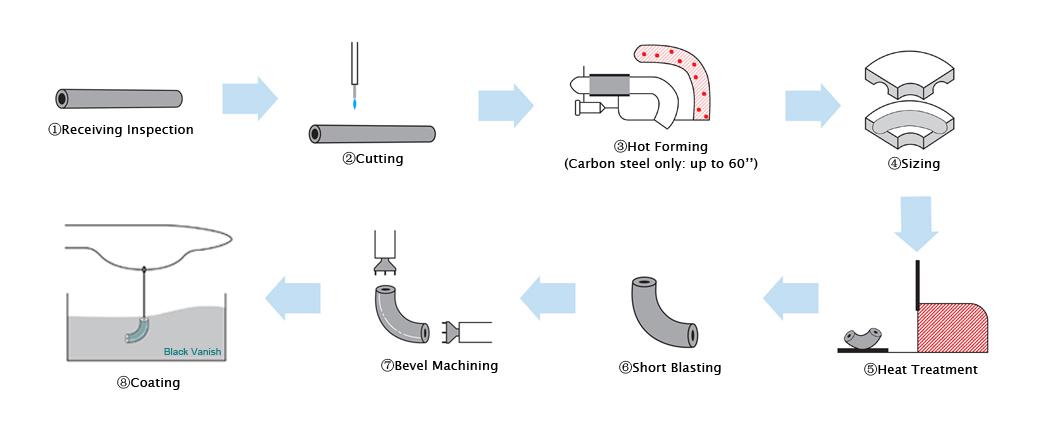

Hot forming is the most commonly way to produce carbon steel elbow. Let us learn more about it from the following video.

The hot forming process pushing elbow is a process that uses special elbow pushing machine, core die and heating device to make the blank on the die move forward under the push of pushing machine, and is heated, expanded and bent during the movement. Hot pushing bend deformation characteristics are based on volume before and after plastic deformation rule of metal materials determine the pipe diameter, pipe diameter bend diameter, through the core module and control the deformation of the process, make the inner arc compressed metal flow, the compensation to other parts of the thinned by hole diameter, wall thickness uniform Angle is obtained.

The characteristic of hot pushing elbow.

The hot pushing elbow forming technology has the characteristics of beautiful appearance, uniform wall thickness and continuous operation, which is suitable for mass production. Therefore, it becomes the main forming method of carbon steel and alloy steel elbow, and is also applied in the forming of stainless steel elbow of some specifications.