Carbon steel equal tee Customer inspection

Carbon steel equal tee Customer inspection

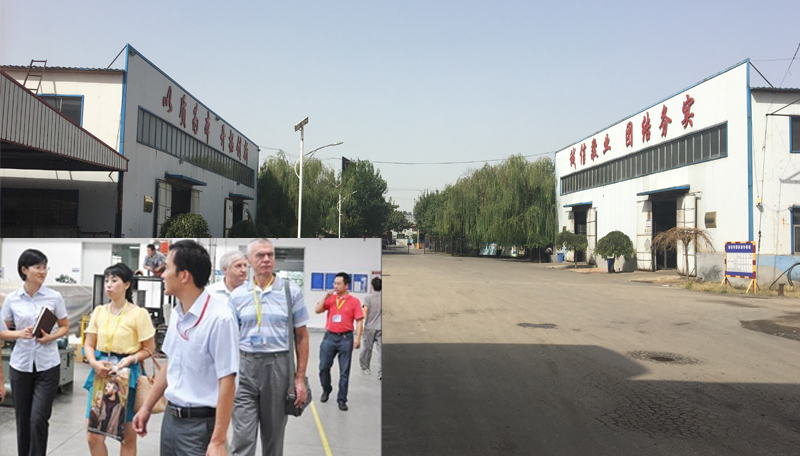

On July 2, 2018, we received the carbon steel equal tee customer inspection, the customer from Malaysia, is the first to purchase our tee products that’s why this test was arranged. Business manager received customers, not only tested the half-finished and finished carbon steel tee, but also visit the elbow and reducer production lines.

Visit the heat treatment of carbon steel equal tee

Carbon steel equal tee design and manufacture must consider the hardness of carbon steel tee, then how to improve the hardness of carbon steel tee, after research we found that the carbon steel three-way heat treatment process, we have to understand the carbon steel tee heat treatment of some knowledge.

The carbon steel equal tee heats up to a certain temperature and keeps it warm for a period of time, and then cools it slowly, called annealing. The annealing of hot-pressing tee is the heat treatment method of heating the steel to the phase change or partial phase transition temperature, and cooling slowly after heat preservation. The purpose of annealing is to eliminate the defects of tissue, improve the composition uniformity of the tissue and refine the grains, improve the mechanical properties of the hot-pressing tee, reduce the residual stress, reduce the hardness, improve the plasticity and toughness, and improve the machining performance.Therefore, annealing is not only to eliminate and improve the previous process of residual tissue defects and internal stress, but also for the follow-up process preparation, so annealing is a semi-finished product heat treatment, also known as the preheat treatment.

Magnetic particle testing of carbon steel equal tee

Because of the carbon steel equal tee production process, the tee production, the essential test is magnetic particle detection. This time we also take customers to the carbon steel tee magnetic particle detection. The principle of magnetic particle testing is that using the method of interaction between the magnetic leakage field and the magnetism powder in the work piece defect, it utilizes the difference between the permeability of the steel product surface and the near-surface defect (such as crack, slag, hairline, etc.) and the magnetic permeability of the steel, after magnetization, the field of the material discontinuity will be changed, a part of the magnetic leakage of the work piece surface generated leakage magnetic field, so as to attract magnetic powder formation defects at the magnetic powder accumulation-magnetic mark, under the appropriate lighting conditions, showing the location and shape of defects.

The carbon steel equal tee customer inspection, a successful conclusion, the customer of our products are very satisfied with the test results, has been appended to the order.