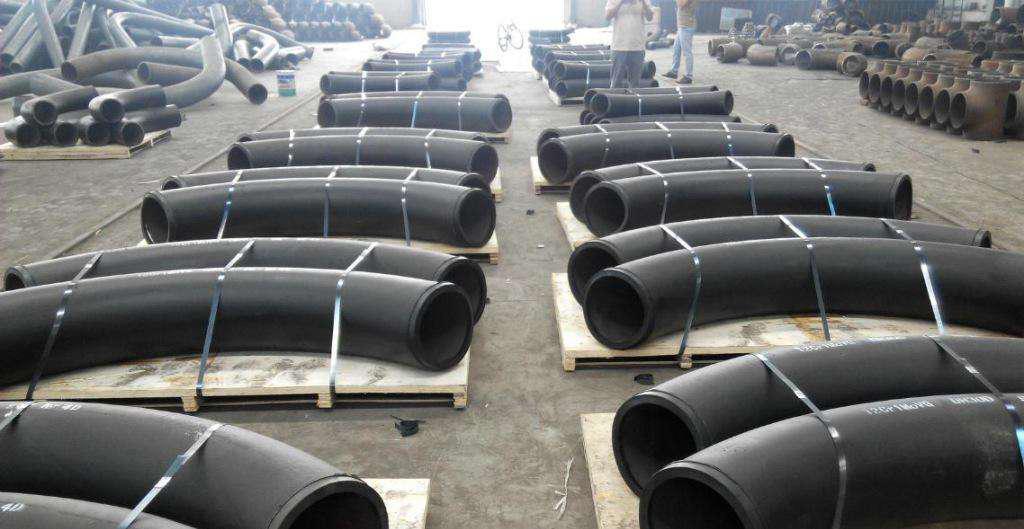

Carbon steel long radius bend

Carbon steel long radius bend

Specializing in the production of carbon steel long radius bend, we have a very rich experience in pipe production and theoretical support. The carbon steel long radius bend we produced, is very popular in many countries in the world , product quality is guaranteed.

Carbon steel long radius bend are pipe fittings that change the direction of the pipe. Bends can be seen in pipes crossing, turning, and around beams. The simmering bending pipe has the advantages of good scalability, high pressure resistance and small resistance. Therefore, it is often used in construction. The main forms of elbow are: elbow of various angles, U-shaped tube, bending back and forth (or the word “B”) and curved curved pipe, etc.,. The carbon steel long radius bend is a pipe fitting with an arbitrary bend angle, which is used at the bend of the pipe. The bend radius of the elbow is indicated by R. When the R is larger, the bending part of the pipe is larger, the bending pipe is relatively smooth, R small, the tube bending part of the smaller, curved more quickly.

Carbon steel long radius bend is a pipe with three bending angles. The middle angle generally becomes 90 °, the side angle becomes 135 °. Arc bends are used to bypass other pipes, and arc bends are often used in piping with sanitary plumbing supplied by cold hot water. The pipe size is determined by the diameter, the bending angle and the bending radius. The bending angle is determined according to the drawing and the actual situation of the construction site, and then the model is made, so the plate is simmering and the bending angle of the pipe is checked according to the sample. Model can be used to simmer round steel, the diameter of the round bar according to the size of the pipe diameter selection, 10-14mm can be. The bending radius of Carbon steel long radius bend shall be determined according to the size of pipe diameter, design requirements and relevant regulations. Neither too large nor too small to choose. Because the bending radius is too large, not only with more materials, and the pipe bending part of the place is also large, which will bring difficulties to the pipeline assembly; The bending radius is selected too small, the elbow wall of the elbows due to excessive elongation and thinning, so that its strength is reduced, and in the elbow side tube wall is compressed, forming a wrinkle state. Therefore, the general rule: the bending radius of the hot-simmer bend should not be less than 3 of the pipe diameter. 5 times times; The bending radius of the cold-simmering elbow shall not be less than 4 times times that of the pipe diameter; The bending radius of the welded elbow shall not be less than 1 of the pipe diameter.

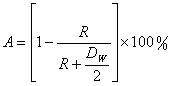

When bending the pipe, the metal in the bending head is compressed, the pipe wall thickens, and the metal on the back of the elbow is stretched and the tube wall is thinned. The smaller the bending radius, the more serious the wall thinning on the back of the elbow, the greater the effect on the strength of the back. In order to make the tube after bending not to the original performance of the major changes, general provisions of the tube after bending, tube wall thinning rate must not exceed 15%.

The tube wall thinning rate can be calculated according to the following formula:

A– The thinning rate (%) of the pipe wall at the outer side of the pipe is bent, the

DW– pipe outer diameter (mm),

R– the bending radius of the bend pipe (mm).

When bending the pipe, due to the change of the wall thickness inside and outside of the tube bending section, the section of the curved section is changed from the original circle to the ellipse. The change of the section shape of the elbow will reduce the cross section area of the pipe, thus increasing the fluid resistance, while also reducing the capacity of the pipe to withstand internal pressure, therefore, the general bending of the oval rate to do the following provisions: the diameter of the pipe is less than or equal to 150mm, the ellipse rate must not be greater than 10%, the diameter is less than or equal to 200mm, The ellipse rate must not be greater than 8%.

![]()

The ellipse rate of the pipe can be calculated by the following formula:

S– ellipse rate (%) in the formula,

D1– the maximum ellipse deformation of the long diameter (mm) ,

D2– the maximum ellipse deformation of the short diameter (mm) .

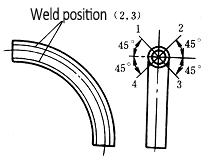

When using water, gas pipe and straight seam welded pipe to make a cold-simmer elbow or hot-simmer elbow, the weld seam of the pipe should be located at 45° from the side center line. In order to avoid bending, pipe weld cracking.

The position of the weld seam when the seam pipe is bent the pipe is generally not allowed to produce wrinkles, if there are individual ups and downs, the height of which is not greater than the following requirements: the diameter is less than or equal to 125mm, shall not exceed 4mm, pipe diameter is less than or equal to 200mm, Before bending is performed, the length of the curved section of the tube must be calculated and the starting point of the bending is drawn, so that the correct semi-finished parts can be obtained after bending.