Carbon steel long radius elbow: material and production scope

What is carbon steel long radius elbow

The difference between carbon steel long radius elbow and short radius elbow

What are the materials of carbon steel long radius elbows?

What are the specifications of carbon steel long radius elbows?

Where are carbon steel long radius elbows used?

The use environment of elbows covers many fields such as industry, construction, chemical industry and water conservancy.

They need to have different characteristics and performance to adapt to different environments and process requirements.

Therefore, when selecting and applying elbows, it is necessary to select appropriate materials and manufacturing processes based on the specific use environment and requirements to ensure that the elbows can operate safely and reliably and meet specific needs and standards.

What is carbon steel long radius elbow

Carbon steel long radius elbow refers to its radius of curvature equal to 1.5 times the outer diameter of the pipe, that is, R=1.5D.

According to the production process, it can be divided into: welded elbow, stamping elbow, pushed elbow, cast elbow, etc.

According to the manufacturing standard, it can be divided into electric standard, water standard, American standard, German standard, Japanese standard, Russian standard, etc.

Our elbows include German standard elbows, Japanese standard elbows, American standard elbows, etc.

Commonly used materials for elbows include cast iron, stainless steel, alloy steel, forgeable cast iron, carbon steel, non-ferrous metals and plastics. They are connected to pipes.

Methods include: direct welding (the most commonly used method), flange connection, hot melt connection, electrofusion connection, threaded connection and socket connection, etc.

The difference between carbon steel long radius elbow and short radius elbow

| Characteristic | Long Radius Elbow | Short Radius Elbow |

|---|---|---|

| Radius of Bend | Has a larger radius of curvature. | Has a smaller radius of curvature. |

| Center-to-Face Dimension | Larger center-to-face dimension, typically 1.5 times the nominal pipe size. | Shorter center-to-face dimension, typically equal to the nominal pipe size. |

| Fluid Flow Resistance | Provides a smoother flow path, minimizing flow resistance. | Introduces more flow resistance due to the abrupt change in direction. |

| Space Requirement | Requires more space for installation. | Suitable for applications with space constraints. |

| Pressure Drop | Generally, lower pressure drop compared to short radius elbows. | Higher pressure drop due to increased flow resistance. |

| Applications | – Commonly used in applications where flow integrity is crucial. | – Ideal for tight spaces where a compact bend is necessary. |

| – Recommended for systems with higher fluid velocities. | – Suitable for areas with spatial limitations. | |

| Piping Systems | Often used in standard piping systems. | Frequently utilized in compact and constrained piping systems. |

| Bend Characteristics | Smooth and gradual bend, less stress on the material. | Sharp and abrupt bend, higher stress on the material. |

| Safety Considerations | May reduce the risk of erosion and corrosion. | Should be carefully selected to minimize impact on flow and system integrity. |

| Common Standards | ANSI/ASME B16.9, ASME B16.28 | ANSI/ASME B16.9, ASME B16.28, MSS-SP-75 |

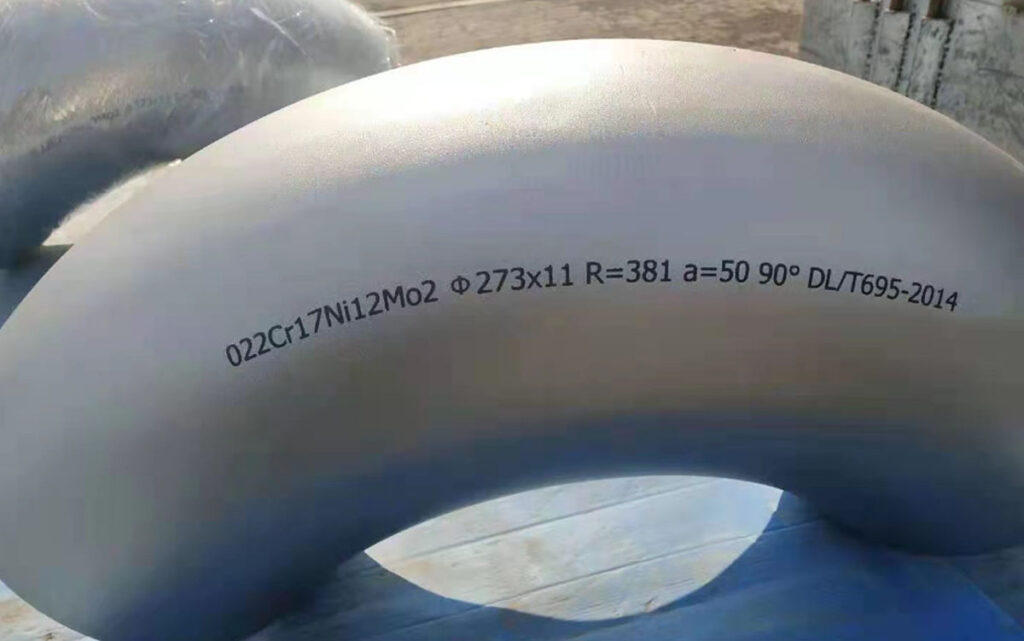

What are the materials of carbon steel long radius elbows?

Carbon Steel: ASTM/ASME A234 WPB, WPC

Alloy: ASTM/ASME A234 WP 1-WP 12-WP 11-WP 22-WP 5-WP 91-WP 911

Stainless steel: ASTM/ASME A403 WP 304-304L-304H-304LN-304N

ASTM/ASME A403 WP 316-316L-316H-316LN-316N-316Ti

ASTM/ASME A403 WP 321-321H ASTM/ASME A403 WP 347-347H

Low temperature steel: ASTM/ASME A402 WPL 3-WPL 6

High Performance Steel: ASTM/ASME A860 WPHY 42-46-52-60-65-70

What are the specifications of carbon steel long radius elbows?

Seamless size: 1/2″~24″ DN15~DN600

Butt welding size: 4″~78″ DN150~DN1900

wall thickness

sch10, sch20, sch30, std, sch40, sch60, xs, sch80, sch100,

sch120, sch140, sch160, xxs, sch5s, sch20s, sch40s, sch80s

Maximum wall thickness: 150mm

Production range

Outer diameter 1/2″~24″ 4″~78″

Wall thickness 2mm~150mm

Bending radius R=1D~10D

Product angle 0°~180°

Where are carbon steel long radius elbows used?

Long-radius elbows are the most commonly used, and are generally long-radius by default.

Long-radius elbows will be used in places with high pressure or high flow rates.

If the resistance requirements of solid conveying pipelines are strict, larger-radius elbows will be used. If there are no restrictions or it is not specified in the contract, long radius elbows are preferred.

Packaging uses wooden boxes, wooden pallets, etc. Long radius elbows are made of stainless steel, carbon steel, alloy steel, etc.

The scope of application includes: sewage treatment, chemical industry, thermal power, pharmaceuticals, aerospace, electric power, paper making and other industries.