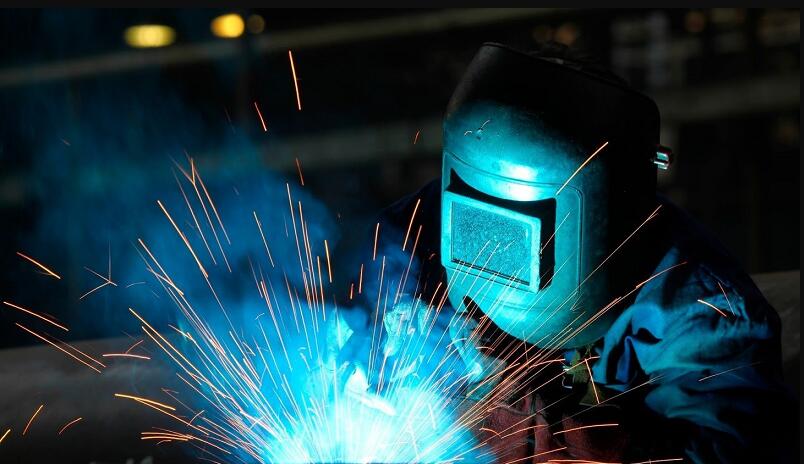

Carbon Steel Pipe Welding Methods and Guidelines

Contents

- Uses of carbon steel pipe

- Pipeline material selection

- Welding methods of carbon steel pipe

- Welding precautions

Carbon steel pipe is a steel pipe with carbon as the main component. According to the different carbon content, carbon steel pipe can be divided into low carbon steel pipe, medium carbon steel pipe and high carbon steel pipe.

Carbon steel pipe has good machinability and weldability and is widely used in petroleum, chemical, electric power, shipbuilding and other fields.

Uses of carbon steel pipe

Carbon steel pipes are widely used in industrial production. They are mainly used to transport liquids, gases, solids and other media, such as oil, natural gas, water, air, coal gas, etc.

In addition, carbon steel pipes can also be used to manufacture mechanical parts, auto parts, building structures and other fields.

Pipeline material selection

When choosing a carbon steel pipeline, you need to consider factors such as the working pressure, temperature, and flow rate of the pipeline in order to select the appropriate pipeline material.

Generally speaking, the higher the working pressure and temperature of the pipeline, the thicker the required pipeline wall, so the corresponding pipeline material must be stronger. In addition, the corrosion resistance and heat resistance of the pipeline also need to be considered.

Welding methods of carbon steel pipe

Carbon steel pipes can be joined using a variety of welding methods, including the following:

Manual arc welding (SMAW)

Manual arc welding is a common welding method. When performing manual arc welding, a handheld electrode is used to introduce current into the arc to connect the steel pipes together.

Gas metal arc welding (GMAW)

Gas metal arc welding is a commonly used automated welding method. When performing gas metal arc welding, inert gas or active gas can be used for protection to avoid the influence of air on welding quality.

Powder metal arc welding (PMAW)

Melting electrode powder welding is an efficient welding method suitable for welding large diameter or thick wall carbon steel pipes.

Plasma welding (PAW)

Plasma welding can form deep welds on carbon steel pipes and is suitable for special welding requirements.

Welding precautions

When welding carbon steel pipes, the following points should be noted:

Pre-treat pipe

Before welding, the pipe needs to be pre-processed, including deburring, grinding and cleaning, etc. This helps to improve the quality of welding.

Choose appropriate welding materials

When welding, you need to choose appropriate welding materials to ensure the quality of welding. Generally, the materials of the welding rod and the pipe should be the same, or the welding rod material should be easier to weld than the pipe material.

Master welding parameters

When welding, it is necessary to master the appropriate welding parameters, including current, voltage and welding speed, etc. If the welding parameters are not set correctly, the welding quality will be reduced.

Pay attention to shielding gas

When performing gas shielded welding, you need to pay attention to the type and flow of shielding gas. The choice of shielding gas should be based on the specific welding materials and welding procedures.

Avoid thermal cracking

When welding, it is necessary to avoid the occurrence of thermal cracking. Generally, the thermal cracking problem can be dealt with by appropriately reducing the welding temperature and generating stress.