carbon steel reducer

What is Carbon steel reducer?

Carbon steel reducer is a kind of pipe fitting that is used to connect pipes of two different diameters, is a kind of welded joint. The main representatives are ASTM A234 WPB, A860 WPHY 65 and A420 WPL6.

According to the different shape, there are concentric reducer and eccentric reducer. The center of a circle on the same straight line at both ends of the pipe is called concentric reducers, otherwise it is called eccentric reducers.

Carbon Steel Concentric Reducer

The concentric reducer is made with both inlet and outlet on a common center line. Compare with eccentric type, it is less costly to manufacture adaptable to most piping installations.

Carbon Steel Eccentric Reducer

The eccentric reducer has the reducing outlet end off center. In contrast with concentric reducer, It can be hung or suspended flush against a flat ceiling or wall.

Carbon steel reducer production

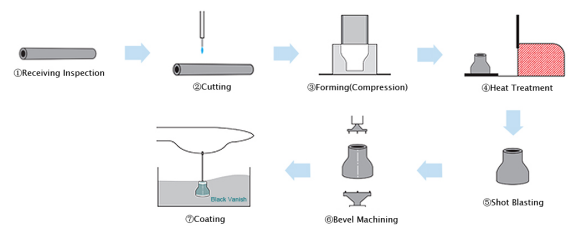

A reducer is a pipe fitting used for pipe calibers. The commonly used forming processes are pressure reduction, expanding pressing or reducing plus expanding pressing. And stamping can also be used for some specifications of reducers.

- Reducing/expanding forming

The process of carbon steel reducer is to put the pipe blank with the same diameter as the big end of the head into the forming mold. By pressing the pipe blank along the axial direction, the metal moves along the die cavity and shrinks to form. According to the size of the reducer, there is one pressing forming or multiple pressing forming.

- Stamping forming

In addition to using steel pipe as raw material to produce the reducer, some specifications of the size of the reducer can also be produced by steel stamping process. Then, as the size of the inner surface of the reducer to design the shape of the drawing mold. The blanked steel plate is pressed and drawn by the die.

The production processing flow of reducer:

What are the main applications of carbon steel reducer?

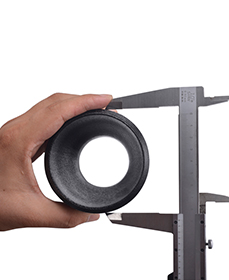

The inside and outside of the large and small heads are treated with high-grade polishing equipment to meet the requirements of surface precision.

- Chemical, petroleum, metallurgy, light industry, electric power, plumbing, food, medicine and other industries of water, gas, steam, oil products and corrosive media control.

- Sanitary valves, fluid pipe fittings, special industry pipe fittings and mechanical supporting equipment, such as dairy, pharmaceutical, beer, beverage, edible oil and other industries.

Why choose us to buy reducer?

Metleader is a manufacturer and exporter of steel pipes, fittings and flanges, which have been exported to many countries and regions with big quantity. What’s more, our company have been passed several certificates including ISO9001: 2008, ISO14001, OHSAS18001, CE certificate, one member of supplier system of Sinopec, and CNPC.

All in all, our company can provide products with excellent quality. Welcome your inquiry timely salesmanager@metleader.com.