Characteristics and applications of A182 F316L stainless steel flange

Where are A182 F316L stainless steel flanges used?

Standards for stainless steel flanges

What types of stainless steel flanges are there?

Comparison of chemical elements and mechanical properties of A182 F316L stainless steel flange

This article focuses on the application of A182 F316L stainless steel flanges in chemical, petroleum, petrochemical, pharmaceutical and other industries, and also introduces the standards and types of stainless steel flanges.

Stainless steel flanges can be manufactured in different materials, standards and types according to different application scenarios.

No matter which type of stainless steel flange, the key advantage lies in its material selection, which can achieve excellent corrosion resistance, high temperature resistance, processability and weldability.

What is A182 F316L flange?

A182 F316L stainless steel flange is a metal material with high strength, high corrosion resistance, high temperature and low temperature resistance, which is widely used in important equipment of LNG ships.

LNG liquefied natural gas ships are an important means of transporting liquefied natural gas (LNG) from the place of production to the place of use, ensuring the effective exploitation and utilization of global natural gas resources.

Due to the low liquefaction temperature of LNG, the transportation process involves the transmission and storage of low-temperature liquid gas, so the performance of the A182 F316L stainless steel flange is very important.

Where are A182 F316L stainless steel flanges used?

Chemical Industry

A182 F316L stainless steel flanges are widely used in the chemical industry because the chemical production process requires high corrosion resistance of equipment.

A182 F316L stainless steel flanges are used in the manufacture of equipment such as reactors, storage tanks, pump valves and pipelines, and corrosive items can be recycled frequently without causing damage to the equipment.

oil industry

A182 F316L stainless steel flange is mainly used in the petroleum industry to produce well pipes, protective casings, drilling pipes and other equipment.

They need to withstand very high pressures and temperatures, and must be able to prevent rust and corrosion, so the stainless steel flange materials used for these equipment often choose the best quality A182 F316L stainless steel flange.

Petrochemical industry

In the petrochemical industry, A182 F316L stainless steel flanges are mainly used to manufacture separation equipment, processing equipment, storage and transportation equipment, etc.

These devices often need to work in high temperatures, high pressures, and corrosive environments while maintaining a high degree of safety.

A182 F316L stainless steel flange can ensure the corrosion resistance and high safety of the equipment.

Pharmaceutical industry

A182 F316L stainless steel flanges are also widely used in the pharmaceutical industry.

In the pharmaceutical manufacturing process, materials must not only ensure purity and cleanliness but also have good processability, so stainless steel flanges are a good choice.

A182 F316L stainless steel flange also has good corrosion resistance, high temperature resistance and weldability, so it is widely used in equipment and container manufacturing in the pharmaceutical industry.

Standards for stainless steel flanges

international standards

Internationally, the standards for stainless steel flanges mainly include JIS, DIN, ISO and BS.

These standards usually have relatively strict quality inspection standards to ensure that the quality of the materials meets the requirements.

And the use of international standard stainless steel flanges can be used worldwide.

American standard

The American system’s stainless steel flange standards are usually set by the American Petroleum Institute (API) or the American Standards and Technical Committee (ASTM).

These standards cover many stainless steel flange specifications and sizes, and have corresponding quality inspection standards.

Japanese standard

In Japan, the main stainless steel flange standard is JIS.

These standards cover many stainless steel flange specifications and sizes, and have corresponding quality inspection standards.

What types of stainless steel flanges are there?

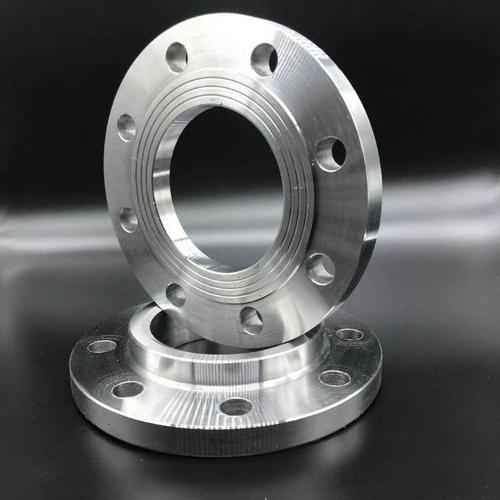

Butt welding flange

Butt welding flange is the most common type of stainless steel flange.

It consists of a flange plate and a set of flange rings.

Flange rings are mainly used to connect pipes, while flange plates are used to connect equipment and pipes. Butt weld flanges usually require the use of welding equipment to secure them to the pipe or equipment.

Blind flange

Blind flange is a closed stainless steel flange.

It is used to plug holes in pipes or equipment, usually when pipe valves or other equipment need to be replaced.

butterfly valve flange

Butterfly valve flange is also a common stainless steel flange.

It installs a butterfly valve in the pipeline and connects it to the pipeline through a flange assembly including the valve.

Comparison of chemical elements and mechanical properties of A182 F316L stainless steel flange

| Material | Chemical Composition | Mechanical Properties |

|---|---|---|

| A182 F304 | C≤0.08, Si≤1.0, Mn≤2.0, P≤0.045, S≤0.03, Ni 8.0-11.0, Cr 18.0-20.0, N≤0.10 | Tensile Strength ≥515 MPa, Yield Strength ≥205 MPa, Elongation ≥35% |

| A182 F304L | C≤0.03, Si≤1.0, Mn≤2.0, P≤0.045, S≤0.03, Ni 8.0-13.0, Cr 18.0-20.0, N≤0.10 | Tensile Strength ≥485 MPa, Yield Strength ≥170 MPa, Elongation ≥35% |

| A182 F316L | C≤0.03, Si≤1.0, Mn≤2.0, P≤0.045, S≤0.03, Ni 10.0-14.0, Cr 16.0-18.0, Mo 2.0-3.0, N≤0.10 | Tensile Strength ≥485 MPa, Yield Strength ≥170 MPa, Elongation ≥35% |

| A182 F321 | C≤0.08, Si≤1.0, Mn≤2.0, P≤0.045, S≤0.03, Ni 9.0-12.0, Cr 17.0-19.0, Ti≥5×C%~0.70 | Tensile Strength ≥515 MPa, Yield Strength ≥205 MPa, Elongation ≥35% |

| A182 F310 | C≤0.25, Si≤1.50, Mn≤2.0, P≤0.045, S≤0.03, Ni 19.0-22.0, Cr 24.0-26.0 | Tensile Strength ≥515 MPa, Yield Strength ≥205 MPa, Elongation ≥35% |

| A182 F316Ti | C≤0.08, Si≤1.0, Mn≤2.0, P≤0.045, S≤0.03, Ni 10.0-14.0, Cr 16.0-18.0, Mo 2.0-3.0, Ti≥5C%~0.70 | Tensile Strength ≥515 MPa, Yield Strength ≥205 MPa, Elongation ≥35% |

| A182 F317L | C≤0.03, Si≤1.0, Mn≤2.0, P≤0.045, S≤0.03, Ni 11.0-15.0, Cr 18.0-20.0, Mo 3.0-4.0, N≤0.10 | Tensile Strength ≥515 MPa, Yield Strength ≥205 MPa, Elongation ≥35% |

| A182 F347 | C≤0.08, Si≤1.0, Mn≤2.0, P≤0.045, S≤0.03, Ni 9.0-13.0, Cr 17.0-19.0, Nb 10×C%~1.00 | Tensile Strength ≥515 MPa, Yield Strength ≥205 MPa, Elongation ≥35% |

| A182 F44 | C≤0.020, Si≤0.50, Mn≤2.00, P≤0.030, S≤0.010, Ni≥24.0, Cr≥20.5, Mo 6.0-7.0, N≥0.18 | Tensile Strength ≥655 MPa, Yield Strength ≥290 MPa, Elongation ≥35% |

| A182 F904L | C≤0.02, Si≤1.00, Mn≤2.00, P≤0.045, S≤0.035, Ni 23.0-28.0, Cr 19.0-23.0, Mo 4.0-5.0, Cu≤2.0 | Tensile Strength ≥490 MPa, Yield Strength ≥215 MPa, Elongation ≥35% |