Compact flange standards, pressure classes and advantages analysis

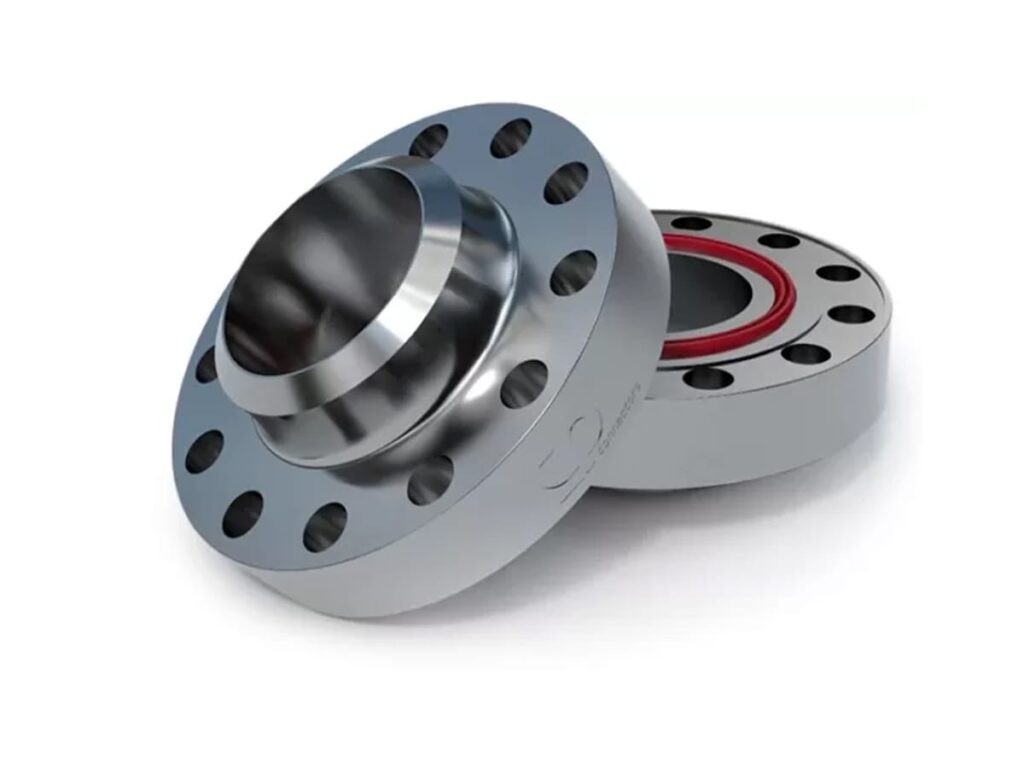

What is a compact flange

Compact flange standard is a kind of pipe connection that adopts efficient design and manufacturing technology.

It is widely used in petroleum, chemical industry, metallurgy, electric power and other industries, and is favored by many industries.

The compact flange standard is characterized by its small size, light weight, easy installation, and is suitable for pipe connection needs in various environments.

Compared with traditional flange standards, compact flange standards not only reduce the difficulty during installation, but also reduce errors during pipeline connection and improve engineering efficiency.

The emergence of compact flange standards meets the higher requirements for pipeline connectors in industrial production, reduces engineering costs, and brings more convenience and benefits to industrial production.

What are the standards for compact flanges?

European flange system

German DIN (including the Soviet Union)

Nominal pressure: 0.1, 0.25, 0.6, 1.0, 1.6, 2.5, 4.0, 6.4, 10.0, 16.0, 25.0, 32.0, 40.0, Mpa;

Calculated diameter: 15~600mm;

Structural types of flanges: flat welding plate type, flat welding ring loose sleeve type, crimping loose sleeve type, butt welding crimping loose sleeve type, butt welding ring loose sleeve type, butt welding type, necked threaded connection type, integral type and flange cover;

Flange sealing surfaces include: flat surface, concave surface, concave and convex surface, tongue and groove surface, rubber ring connection surface, lens surface and diaphragm welding surface;

The OCT pipe flange standard issued by the Soviet Union in 1980 is similar to the German DIN standard.

American flange system

American flange system: American ANSI B16.5 “Steel Pipe Flanges and Flange Fittings”

Nominal pressure: 150psi (2.0Mpa), 300psi (5.0Mpa), 400psi (6.8Mpa), 600psi (10.0Mpa), 900psi (15.0Mpa), 1500psi (25.0Mpa), 2500psi (42.0Mpa);

Calculated diameter: 6~4000mm;

Flange structural types: strip welding, socket welding, threaded connection, loose sleeve, butt welding and flange cover;

Flange sealing surface: concave surface, concave and convex surface, tongue and groove surface, metal ring connection surface.

Advantages of compact flanges

Small size and light weight: The compact flange structure design reduces costs and difficulty in transportation and installation.

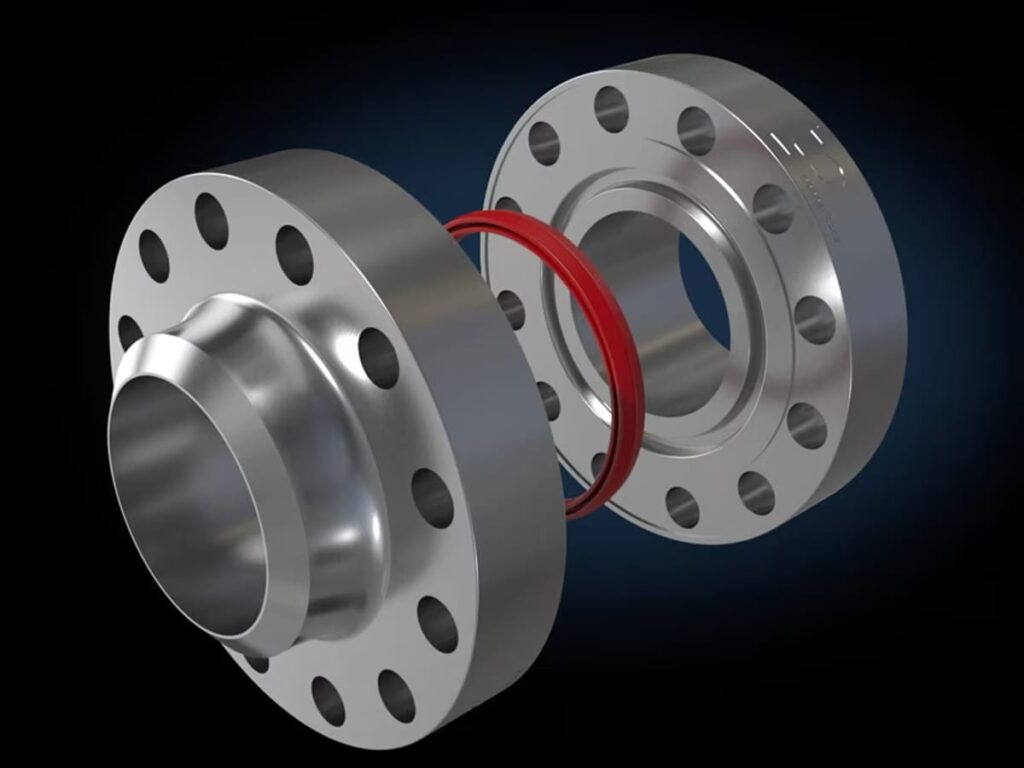

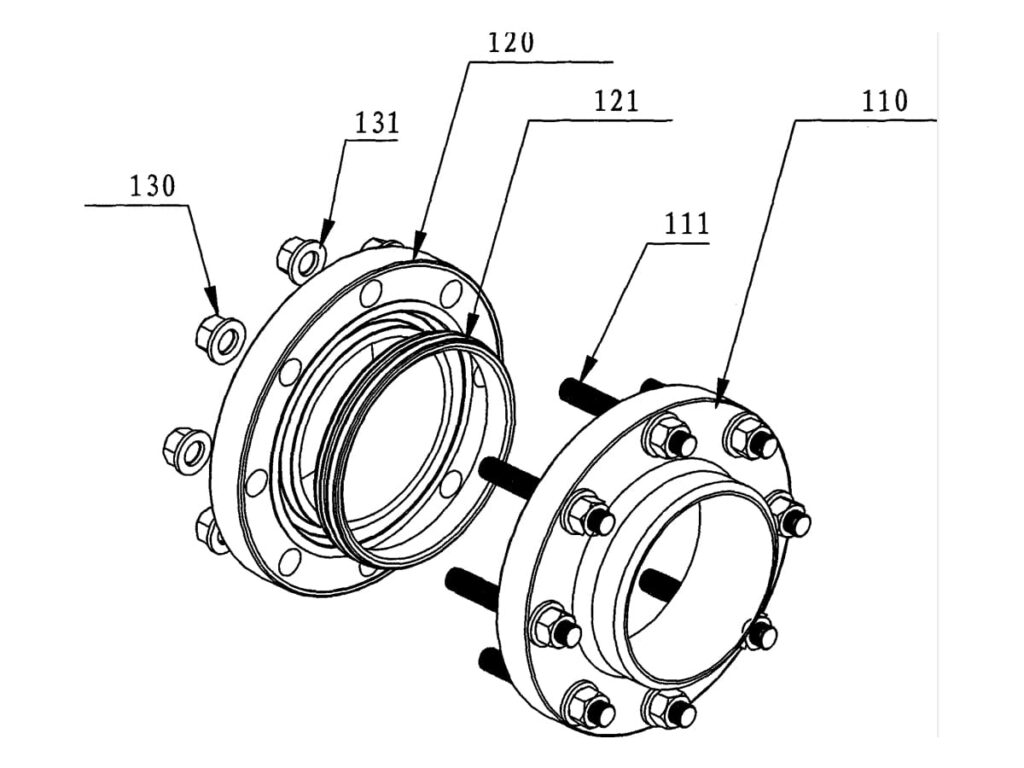

Good sealing performance: special sealing structure ensures stable and safe connection.

Easy installation: Bolt tightening improves engineering efficiency.

Strong versatility: meet a variety of engineering needs and reduce inventory costs.

Pressure Ratings for Compact Flanges

Compact flanges are also available outside the product standard, both in terms of dimensions and design pressures as follows:

API pressure rating 5kpsi, sizes up to 48 inches.

API pressure rating 7.5kpsi, sizes up to 24”.

API pressure rating 10kpsi, sizes up to 24”.

API pressure rating 15kpsi, sizes up to 24″.

API pressure rating 20kpsi available on request.

Compact flanges typically weigh 70 to 80 percent less than traditional ANSI flanges.

These flanges feature double independent seals, making them safer. In addition, these flanges have an integrated sealing system both inside and outside the flange, which allows them to have a wider design pressure and temperature range.

These flanges are used on pipe sizes from 0.5 to 48 inches (1.27 to 122 cm) in pressure ratings from Class 150 to Class 2500 specifications.