Comprehensive understanding of butt welding ring loose flange

What is the standard for butt welding ring loose flange?

What is the difference between butt welding ring loose flange and flat welding ring loose flange?

What should we pay attention to when applying welding ring loose flange?

Connection method of butt welding ring loose flange

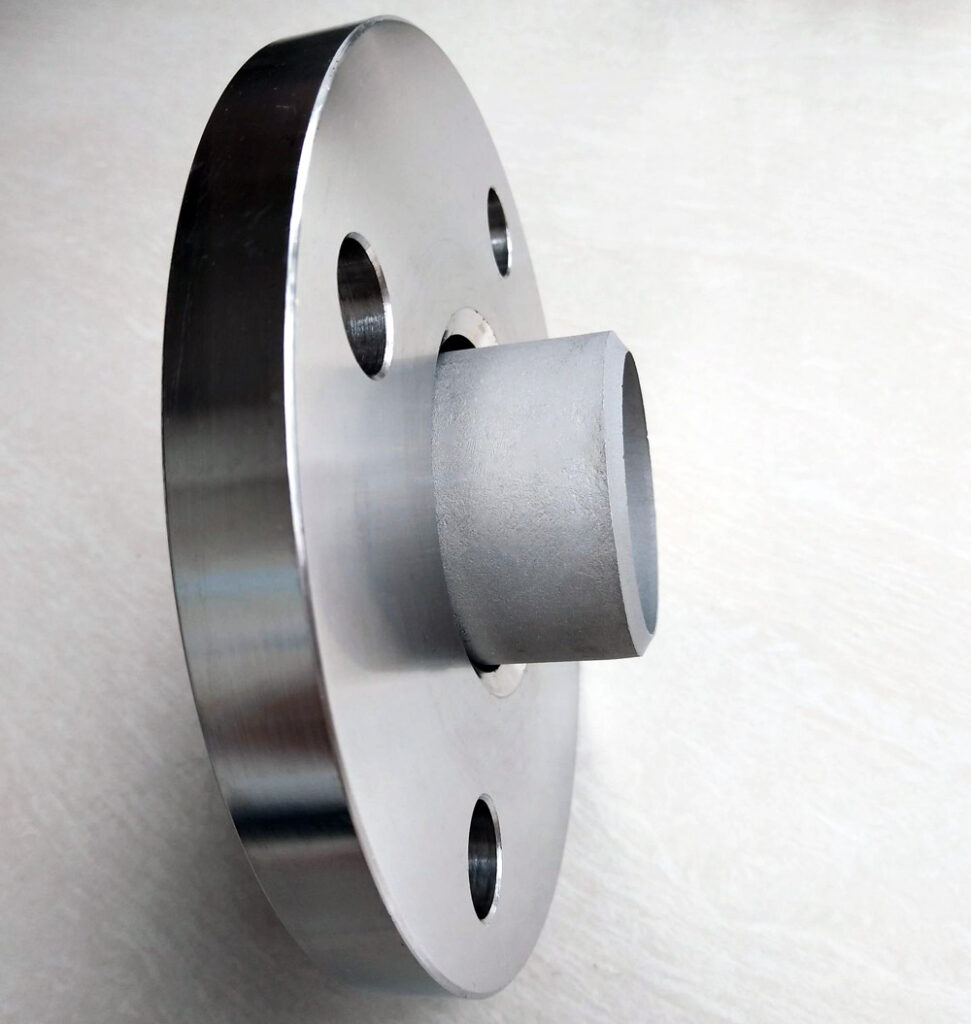

Butt welding ring loose sleeve flanges are generally matched with water supply and drainage accessories, directly connected with bolts, and are easy to install.

This type of flange is currently widely used in some low-pressure environments.

Metleader has exported this type of flange to Africa and Arab countries. , India, Vietnam, Kazakhstan, Belarus as well as the United Kingdom, Peru and other countries, customer feedback is very good.

We can customize production according to customer requirements, strictly control quality, and ensure that the product qualification rate reaches 100%.

If you want to know the quotation of butt welding ring loose flange, you can provide your email and we will have an engineer at 12 We will contact you within hours.

What is the standard for butt welding ring loose flange?

National standard: GB/T9112-2000 (GB9115.1-2000~GB9115.4-2000)

American Standard: ANSI B16.5 Class150, 300, 600, 900, 1500 (WN, SO, BL, TH, LJ, SW)

Japanese standard: JIS 5K, 10K, 16K, 20K (PL, SO, BL, WN, TH, SW)

Among them, ASME B16.5 is the most widely used standard internationally.

This standard stipulates important parameters such as flange size, material, and pressure level to ensure the safety and reliability of butt welding ring loose flanges.

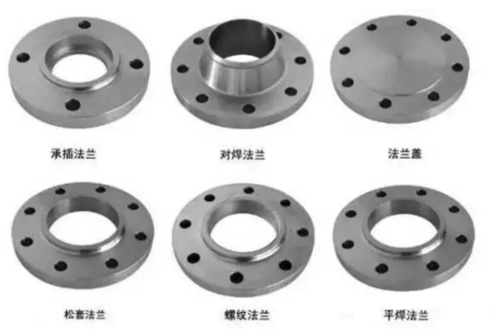

When to choose loose flange?

The purpose of the loop flange is mainly to ensure that there are no welds inside the pipeline.

If there are strict requirements on the inside of the pipeline, a loop flange needs to be used.

For example, in pneumatic conveying systems, if the inside of the pipeline requires internal processing and cannot have welds, a loop flange must be used.

At the same time, if you want to save costs, you can use loop flanges for stainless steel pipes.

In this way, the flange can be made of carbon steel and the inner flange can be made of stainless steel, instead of using an all-stainless steel flange, which can significantly save costs.

For highly corrosive media in pipelines, use butt welding ring loose sleeve flanges, use titanium flanges for flanges, and use stainless steel flanges for the fastening parts, which can greatly reduce costs and play the same role in use.

Titanium flange has the same corrosion resistance.

What is the difference between butt welding ring loose flange and flat welding ring loose flange?

| Characteristic | Butt Welding Ring Loose Flange | Flat Welding Ring Loose Flange |

|---|---|---|

| Connection Type | Butt welding connection with a pipe through welding. | Flat welding connection with a pipe through welding. |

| Flange Face Type | The flange face can be flat or raised, depending on design. | The flange face is typically flat. |

| Welding Process | Requires butt welding, which involves welding the flange to the pipe end. | Requires flat welding, where the flange is welded to the pipe end. |

| Ease of Welding | Generally more complex welding process due to the butt weld configuration. | Generally simpler welding process due to the flat weld configuration. |

| Strength and Integrity | Butt welding provides a strong and integral connection between the flange and the pipe. | Flat welding provides a strong connection, but not as integral as butt welding. |

| Surface Finish | The flange face can be flat or raised, affecting the surface finish. | Typically has a flat flange face, providing a consistent surface finish. |

| Gasket Compatibility | Compatible with various gasket materials suitable for the specific flange face. | Compatible with gaskets suitable for flat flange faces. |

| Applications | Commonly used in applications where a butt weld connection is preferred or required. | Commonly used in applications where a flat weld connection is suitable. |

| Alignment and Precision | Requires precise alignment during the butt welding process. | Easier to align during the flat welding process. |

| Pressure Rating | Can have high pressure ratings depending on design and materials. | Can have high pressure ratings depending on design and materials. |

| Common Standards | Conforms to standards such as ASME B16.5 or ASME B16.47. | Conforms to standards such as ASME B16.5 or ASME B16.47. |

What should we pay attention to when applying welding ring loose flange?

During installation and induction, pay attention to the positioning of the bracket to avoid unnecessary damage;

Appropriate materials and gaskets should be selected according to the working environment and the nature of the medium;

Butt welding ring loose flanges should be selected and applied according to the models and specifications specified in the standard;

During use, operate in strict accordance with the standards to avoid safety accidents caused by overload and negligence.

Connection method of butt welding ring loose flange

Butt weld ring loose flange connection is a very common connection method used when multiple pipes are connected together.

The characteristic of this connection method is that there is a fixed connector at one end and a freely removable connector at the other end.

Different connection functions can be achieved by changing different connectors.

This connection method is widely used in engineering, and most pipeline systems will use this connection method to achieve fast and accurate connection work.

Its principle is to connect two pipes together to form a complete pipe system.

When connecting, the pipe connector at one end is flexibly connected to the connector at the other end. By tightening the bolts, the two are firmly connected to form a complete pipeline system.