Detailed explanation of stainless steel pipe hardness

Stainless steel pipes generally use three hardness indicators: Brinell, Rockwell, and Vickers to measure their hardness.

Stainless steel pipe is an economical cross-section steel and an important product in the steel industry.

It can be widely used in life decoration and industry.

Many people on the market use it to make stair handrails, window guards, railings, furniture, etc.

There are two common materials: 201 and 304.

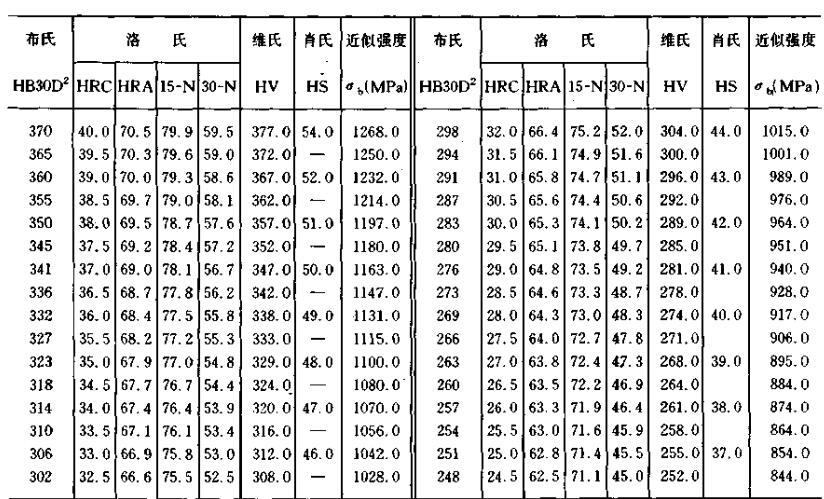

Brinell hardness

Among stainless steel pipe standards, Brinell hardness is the most widely used.

The indentation diameter is often used to express the hardness of the material, which is both intuitive and convenient.

But it is not suitable for steel pipes made of harder or thinner steel.

Rockwell hardness

The Rockwell hardness test of stainless steel pipe is the same as the Brinell hardness test, which is an indentation test method.

The difference is that it measures the depth of the indentation. Rockwell hardness test is currently a widely used method, among which HRC is used in steel pipe standards second only to Brinell hardness HB.

Rockwell hardness can be used to measure metal materials from extremely soft to extremely hard. It makes up for the shortcomings of the Brinell method.

It is simpler than the Brinell method and the hardness value can be read directly from the dial of the hardness machine. However, due to its small indentation, the hardness value is not as accurate as the Brinell method.

Vickers hardnes

The Vickers hardness test of stainless steel pipe is also an indentation test method that can be used to determine the hardness of very thin metal materials and surface layers.

It has the main advantages of Brinell and Rockwell methods and overcomes their basic shortcomings, but it is not as simple as Rockwell method.

Vickers method is rarely used in steel pipe standards.

Connection method

There are various connection methods for stainless steel pipes.

Common pipe fitting types include compression type, compression type, union type, push type, push thread type, socket welding type, union flange connection, welding type and welding and traditional connection.

Combined derived series connection methods. These connection methods have different application scopes according to their different principles, but most of them are easy to install, strong and reliable.

The sealing ring or gasket material used for the connection is mostly made of silicone rubber, nitrile rubber and EPDM rubber that meet national standards, which relieves users from worries.