Comparison of the advantages and disadvantages of 10 different types of pipe flanges

Flange joint is a component that is very commonly used in engineering design and covers a wide range of areas.

It is an indispensable part in piping design, pipe fittings and valves, and is also an essential component in equipment and equipment parts.

It contains 12 different types of pipe flanges. Let’s take a look at their respective advantages and disadvantages.

Butt welding ring loose sleeve flange

Flat welding ring loose sleeve flange

There are two main international pipe flange standards, namely the European pipe flange system represented by German DIN and the American pipe flange system represented by American ANSI pipe flanges.

Plate flat welding flange

Advantage:

Convenient to obtain materials, simple to manufacture, low cost and widely used.

shortcoming:

It has poor rigidity, so it must not be used in chemical process piping systems with supply and demand, flammable, explosive and high vacuum requirements and in highly and extremely hazardous situations.

The sealing surface types include flat and raised surfaces.

Flat welding flange with neck

Advantage:

On-site installation is more convenient, and the process of patting and rubbing the welds can be omitted.

shortcoming:

The neck height of the flat-welded flange with neck is lower, which improves the stiffness and load-bearing capacity of the flange.

Compared with butt welding flanges, the welding workload is large, the welding rod consumption is high, and it cannot withstand high temperature and pressure, repeated bending and temperature fluctuations.

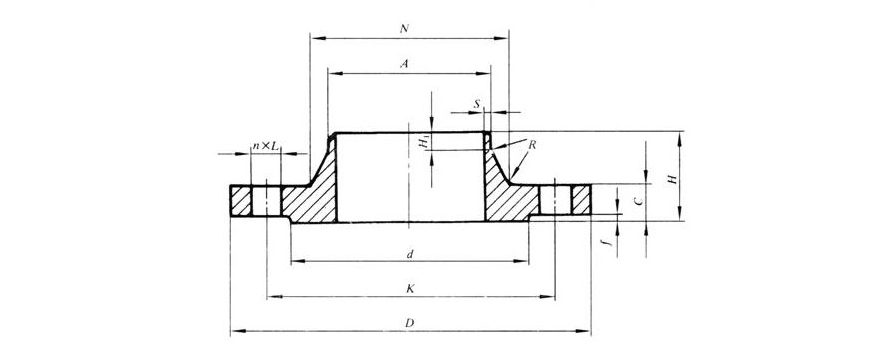

Butt welding flange with neck

Advantage:

The connection is not easy to deform, the sealing effect is good, and it is widely used. It is suitable for pipelines with large fluctuations in temperature or pressure or pipelines with high temperature, high pressure and low temperature.

It is also used for pipelines transporting expensive media, flammable and explosive media, and toxic gases.

shortcoming:

The necked butt welding flange is bulky, heavy, expensive, and difficult to install and position. Therefore, it is more likely to be bumped during transportation.

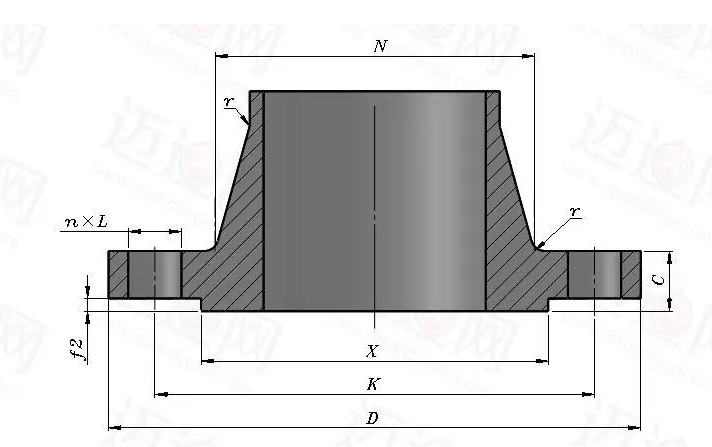

Integral flange

The integral flange is a flange connection method. It is also a type of neck butt welded steel pipe flange.

Materials include carbon steel, stainless steel, alloy steel, etc.

It is mostly used in pipelines with high pressure. The production process is generally casting.

Socket weld flange

Sealing surface form:

Raised surface (RF), concave and convex surface (MFM), tongue and groove surface (TG), ring connection surface (RJ)

Application scope:

Boiler and pressure vessel, petroleum, chemical industry, shipbuilding, pharmaceutical, metallurgy, machinery, stamping elbow, food and other industries.

Commonly used in pipelines with PN≤10.0MPa and DN≤40.

Threaded flange

advantage:

Threaded flanges are easy to install and maintain, and can be used on some pipelines where welding is not allowed on site.

shortcoming:

It is recommended not to use threaded flanges to avoid leakage when the pipe temperature changes rapidly or when the temperature is higher than 260°C and lower than -45°C.

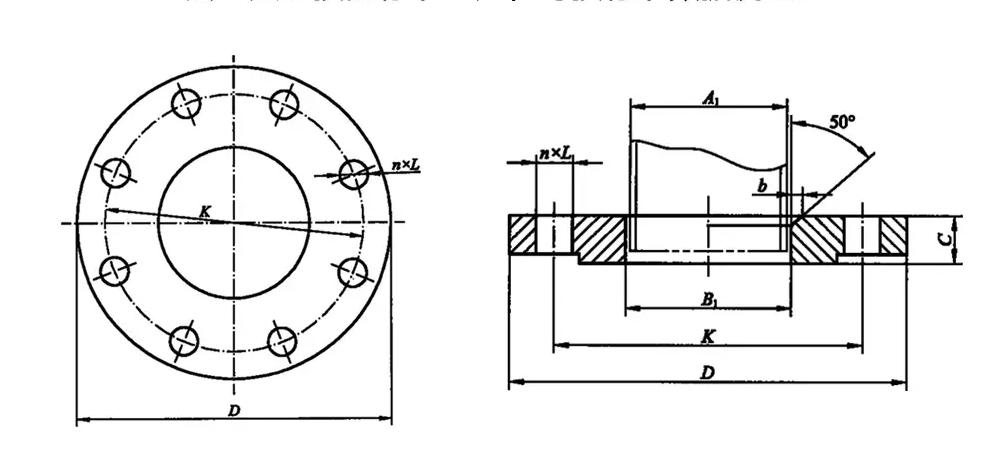

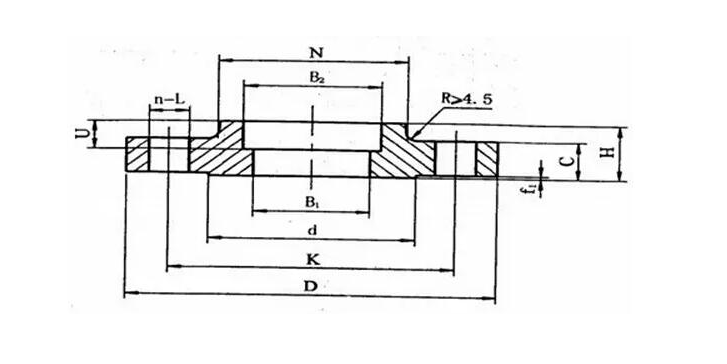

Butt welding ring loose sleeve flange

advantage:

save costs. Easy to construct. For example, it is difficult to align the flange bolt holes when connecting or prevent the flange bolt holes from changing when replacing equipment in the future.

shortcoming:

Low stress tolerance. The strength of the welding ring is low (especially when the thickness is less than 3mm)

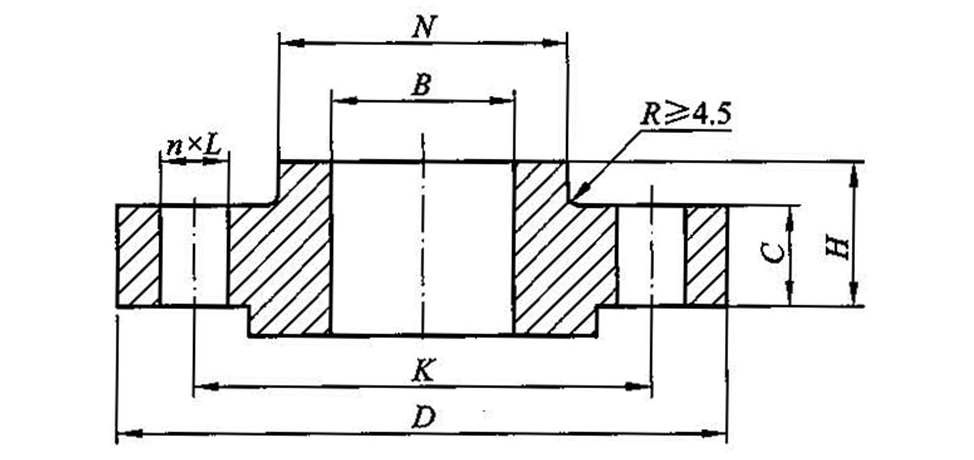

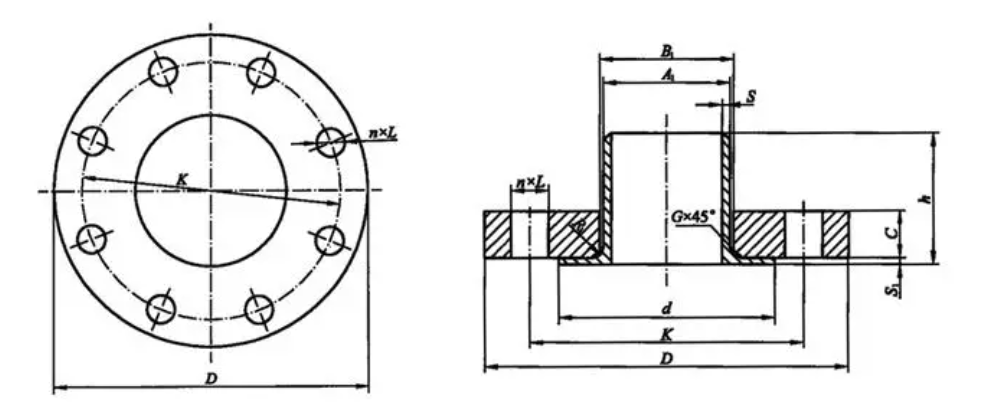

Flat welding ring loose sleeve flange

advantage:

Convenient for welding or processing or requiring high strength, such as plastic pipes, fiberglass pipes, etc. Convenient construction and cost saving.

shortcoming:

Accept that the stress is low. The strength of the welding ring is low (especially when the thickness is less than 3mm)

blind flange

The function is the same as that of welded heads and threaded pipe caps, except that the blind flange and threaded pipe caps can be removed at any time, but the welded heads cannot.

There are many types of sealing surfaces, including full plane, raised surface, concave and convex surface, tongue and groove surface, and ring connection surface. The main production area is in Mengcun area.

Lined flange cover

The lining flange cover is a blind flange, with stainless steel surfacing on the side close to the medium, forming a whole.

Lined flange covers are used as blind plates on pipelines with corrosive media.

The difference from ordinary flange covers is that an anti-corrosion lining is added to the contact surface with the medium.