Structural characteristics of eccentric reducer

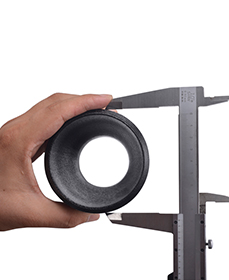

The roundness of eccentric reducer should not be greater than 1% of the diameter of the corresponding end, and the allowable deviation shall be within 3mm. The raw material standard should be according to ISO-SY/T5037, GB/T9711, GB/T8163, ASTM A106/A53, ASTM A105, ASTM A234, ASTM A106, DIN German standard and customer requirements standard.

The Reducer is a pipe fitting for changing the pipe diameter. The forming process is usually used for reducing the compression, expanding the diameter or reducing the diameter and expanding the diameter, and some specifications of the reducer can also be used stamping forming.

A. necking/expanding forming

The shrink-forming process of the reducer is in the forming die, which is equal to the big diameter of the reducer, and through the pressing of the axial direction of the tube billet, the metal moves along the mold cavity and shrinks into shape. According to the size of diameter reducer, it is divided into one pressing forming or multiple pressing forming. The following diagram is the drawing diagram of the concentric reducer.

The expanded-diameter forming is a tube blank which is smaller than the diameter of the different diameter pipe, and the inner diameter of the internal die is expanded. The expanding process mainly solves the problem that the reducer with large diameter is not easy to be formed by necking, and sometimes the method of expanding and reducing is combined according to the need of material and product forming.

In the process of shrinkage or expansion, the cold pressure or hot pressing is determined according to different materials and varying diameters. Under normal circumstances, as far as possible cold pressure, but on multiple diameter to cause serious hardening of the situation, thick wall thickness or alloy steel materials should be used hot pressing.

B. Stamping forming

In addition to the use of steel pipe as raw material for the production of reducer, the partial size of the reducer can also be used for steel plate stamping process for production. The shape of the die used in drawing refers to the design of the surface size of the reducer, and the stamping of the steel plate after the blanking is made.