Common materials and specifications of eccentric reducers

Specifications of eccentric reducer

Packaging method of eccentric reducer

The purpose of eccentric reducer

Classification of eccentric reducers

Standards for eccentric reducers

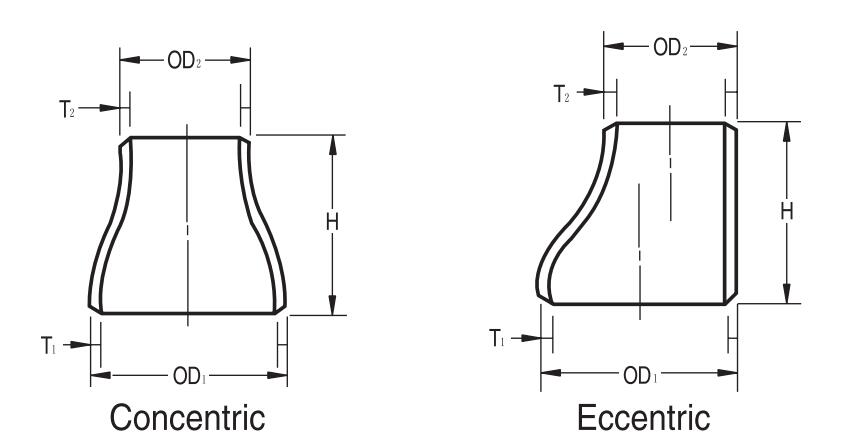

Eccentric large and small heads refer to large and small heads where the center of the circle is not on the same straight line.

Its function is to run pipelines against the wall or the floor without taking up space, and to connect two pipes of different diameters to change the flow rate.

Specifications of eccentric reducer

3/4″ X1/2″ — 48″ X 40″ [DN 20 X 15 — 1200 X 1000]

Packaging method of eccentric reducer

Fumigation-free wooden boxes and pallets can be specially packaged according to customer requirements.

The purpose of eccentric reducer

Petroleum gas pipeline engineering, natural gas pipeline engineering, chemical plants, power plants, shipyards, pharmaceuticals, dairy products, beer, beverages, water conservancy, etc.

Material of eccentric reducer

Carbon steel: 10#, 20#, A3, Q235A, 20G, 16Mn, ASTM A234, ASTM A105, etc.

Stainless steel: ASTM A403, 1Cr18Ni9Ti, 0Cr18Ni9, 00Cr19Ni10, 00Cr17Ni14Mo2, 304, 304L, 316, 316L, etc.

Alloy steel: 16MnR, Cr5Mo, 12Cr1MoV, 10CrMo910, 15CrMo, 12Cr2Mo1, A335P22, St45.8/Ⅲ, A10bB

Classification of eccentric reducers

Carbon Steel: ASTM/ASME A234 WPB, WPC

Alloy: ASTM/ASME A234 WP 1-WP 12-WP 11-WP 22-WP 5-WP 91-WP911, 15Mo3 15CrMoV, 35CrMoV

Stainless steel: ASTM/ASME A403 WP 304-304L-304H-304LN-304N

ASTM/ASME A403 WP 316-316L-316H-316LN-316N-316Ti

ASTM/ASME A403 WP 321-321H ASTM/ASME A403 WP 347-347H

Low temperature steel: ASTM/ASME A402 WPL3-WPL 6

High Performance Steel: ASTM/ASME A860 WPHY 42-46-52-60-65-70

Cast steel, alloy steel, stainless steel, copper, aluminum alloy, plastic, argon phosphate, PVC, PPR, RFPP (reinforced polypropylene), etc.

Standards for eccentric reducers

There are two main international pipe flange standards, namely the European pipe flange system represented by German DIN (including the former Soviet Union) and the American pipe flange system represented by American ANSI pipe flanges.

In addition, there are Japanese JIS pipe flanges, but they are generally only used in public projects in petrochemical plants and have little impact internationally.

Here is an introduction to pipe flanges in various countries:

- The European system pipe flange represented by Germany and the former Soviet Union

- American system pipe flange standards, represented by ANSI B16.5 and ANSI B 16.47

- British and French pipe flange standards, each country has two casing flange standards.

To sum up, the internationally accepted pipe flange standards can be summarized into two different and non-interchangeable pipe flange systems: one is the European pipe flange system represented by Germany; the other is represented by the United States. American pipe flange system.

IOS7005-1 is a standard promulgated by the International Organization for Standardization in 1992.

This standard is actually a pipe flange standard that merges two series of pipe flanges from the United States and Germany.