Electric Resistance Weld (ERW) Carbon Steel Pipe

Electric Resistance Weld (ERW) Carbon Steel Pipe

What is ERW Carbon Steel Pipe?

ERW carbon steel pipe is a type of pipe formed by resistance welding. Unlike seamless steel pipe, it has a welded joint in its cross section. Because the processes involved in the production process of ERW carbon steel pipes are very sampled, the production efficiency is greatly improved and the production cost is effectively reduced. This helps reduce the price of ERW steel pipes. Therefore, this type of steel pipe is increasingly used for water and gas transmission, structural and engineering purposes.

Carbon steel erw pipe specifications:

Electric Resistance Weld (ERW) Carbon Steel Pipe is manufactured by cold forming carbon steel into pipe. The pipe is formed by rolling carbon steel plate and then welding the seam with an electric current.

Product Description:

| Material Standard | ASTM, ASME and API |

| Standard Grades | A53A, A53B, & API 5LB, API 5L X42, API 5L X52, API 5L X60, API 5L X65, X70 |

| Size | 1/2 to 36 inch NB |

| Schedules | SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, to SCH 160 |

| Thickness | 3-12 millimeter |

| Length Range | 20 FT (6 meter), 40FT (12 meter)or customized |

| Ends Type | Beveled ends, Plain ends, Threaded |

| End Protection | plastic Caps or iron Caps |

| Surface treatment | Black rust-proof oil, transparent oil, hot galvanizing, 3PE, epoxy coating |

| Packing | In bundles or according to customers’ requirements |

| Application | Gas, heating, water Transportation, construction, mechanical application, aviation, offshore platform, etc |

ERW steel pipe application and usage:

ERW carbon steel pipe represents resistance welding, resistance welding has the advantages of high production efficiency, low cost, material saving, easy automation and so on. It is one of the important welding processes. Therefore, it is used for transporting gas and liquid objects such as oil and gas, could meet the low and high pressure requirement. In recent years, with the development of ERW technology, more and more ERW steel pipe used in aviation, aerospace, energy, electronics, automobile, light industry and other industrial sectors.

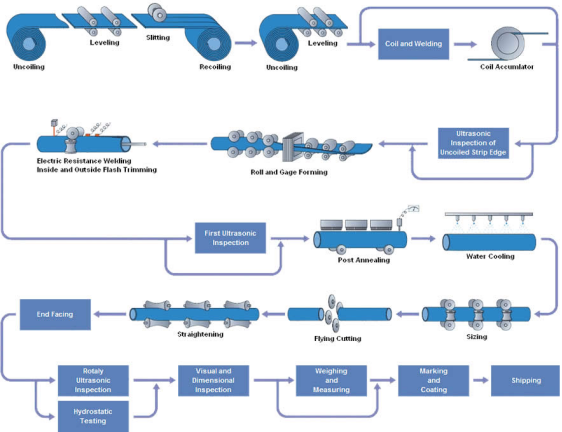

Manufacturing Process:

Electric resistance welded steel pipe (ERW) is a production method in which flat steel strip is cold formed into round tubes and longitudinal seams are obtained through a series of forming rolls. The two edges are then heated simultaneously with a high-frequency current and squeezed together to form a bond. No filler metal is required for longitudinal ERW welds.

China ERW carbon steel pipe suppliers:

As a leading supplier of carbon steel pipes and fittings, Beijing Metleader Pipeline Technology Inc. was established in 1982 and is a well-known manufacturer, trader and supplier of carbon steel equal tee. Our goal is to provide high quality products at competitive prices, and top-notch service to customers around the world. We are ISO9001, CE, and GS certified and strictly adhere to their quality specifications for ERW carbon steel pipe.

We have adopted advanced production equipment and technologies to manufacture our carbon steel pipe fitting, which can not only improve product quality, but also save raw materials. Our products have high strength, good toughness and resistance to corrosion. ERW carbon steel pipes are available in a variety of sizes, shapes, and dimensions, and can also be customised to meet our customers’ specific requirements. Buyers are welcome to contact us.