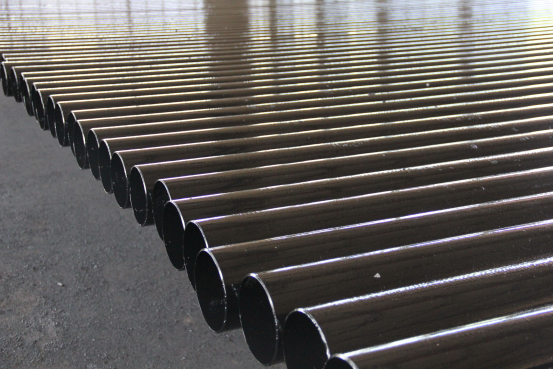

ERW carbon steel pipe for sale

ERW carbon steel pipe for sale

What is erw carbon steel pipe?

“ERW carbon steel pipe” is straight seam Resistance Welding pipe, English Electric Resistance Welding, abbreviated as ERW, used for conveying oil, gas and other vapors and liquid objects, can meet the requirements of high and low pressure, in the field of transmission pipe plays a pivotal role in the world.

It has the advantages of using hot rolled coil as raw material, the wall thickness can be controlled within ±0.2mm, the two ends of the steel pipe according to the American APl standard or GB/T9711.1 standard, repair end groove, fixed length delivery, etc. In recent years, various natural gas pipe network projects and gas companies have widely adopted ERW steel pipe as the main pipe of urban pipe network.

Application:

The welding process of erw high-frequency resistance welded steel pipe is different from that of ordinary welded pipe. The weld is made of the base metal of the steel strip body, and the mechanical strength is better than that of ordinary welding.

ERW stands for resistance welding, resistance welding has the characteristics of high production efficiency, low cost, material saving, easy automation and so on, so it is widely used in aviation, aerospace, energy, electronics, automobile, light industry and other industrial sectors, is one of the important welding processes.

The biggest difference between ERW steel pipe and seamless steel pipe:

The biggest difference between erw steel pipe and seamless steel pipe is that erw has a weld, which is also the key to the quality of ERW steel pipe. Due to the international, especially the United States for many years of unremitting efforts, the seamless ERW steel pipe has been a relatively satisfactory solution.

Some people divide the seamless process of ERW steel pipe into geometric seamless and physical seamless.

Geometric seamless is to remove the inner and outer burrs of the ERW steel pipe. Because of the structure of the internal burr removal system and the continuous improvement and perfection of the tool, the removal of burr in the large and medium diameter steel pipe has been better treated. The internal burr can be controlled at about -0.2mm ~ O.5mm.

Physical seamless refers to the difference between the microstructure inside the weld and the base metal leads to the decrease of the mechanical properties of the weld area, so it is necessary to take measures to make it uniform and consistent.

The thermal process of high frequency welding of ERW steel pipe causes the temperature distribution gradient near the edge of the tube blank, and forms the characteristic regions such as melting zone, semi-melting zone, superheated structure, positive zone, incomplete positive zone and reignition zone. Among them, the welding temperature of the microstructure in the superhot zone is above 1000℃, which makes the austenite grains grow rapidly, so that the hard and brittle coarse crystal phase will be formed under the cooling condition. In addition, the existence of temperature gradient will produce welding stress. In this way, the mechanical properties of the weld area are lower than that of the base metal.

Physical seamless through the local conventional heat treatment process of the weld, that is, the weld area is heated to AC3(927℃) by an intermediate frequency induction heating device, and then the air cooling process of 60m length and 20m/ min speed is carried out, and then water cooling is carried out when necessary. This method is designed to relieve stress, soften and refine microstructure, and improve the comprehensive mechanical properties of welding heat affected zone. So far, the advanced ERW units in the world have generally adopted this method to treat the welds, and have obtained good results. The high quality ERW steel pipe not only cannot identify the weld, but also the weld coefficient reaches 1, which realizes the matching between the weld zone structure and the base metal.