Application of pipe flanges in the petrochemical industry

Catalog

- Classification of pipe flanges

- Applications of pipe flanges

- What types of flanges are used in the petrochemical industry

- Summary

Pipe flange is an important part for connecting pipes and equipment. Flange plays a very important role in the pipeline system. According to the different flange connection conditions, pipe flange can be divided into many types.

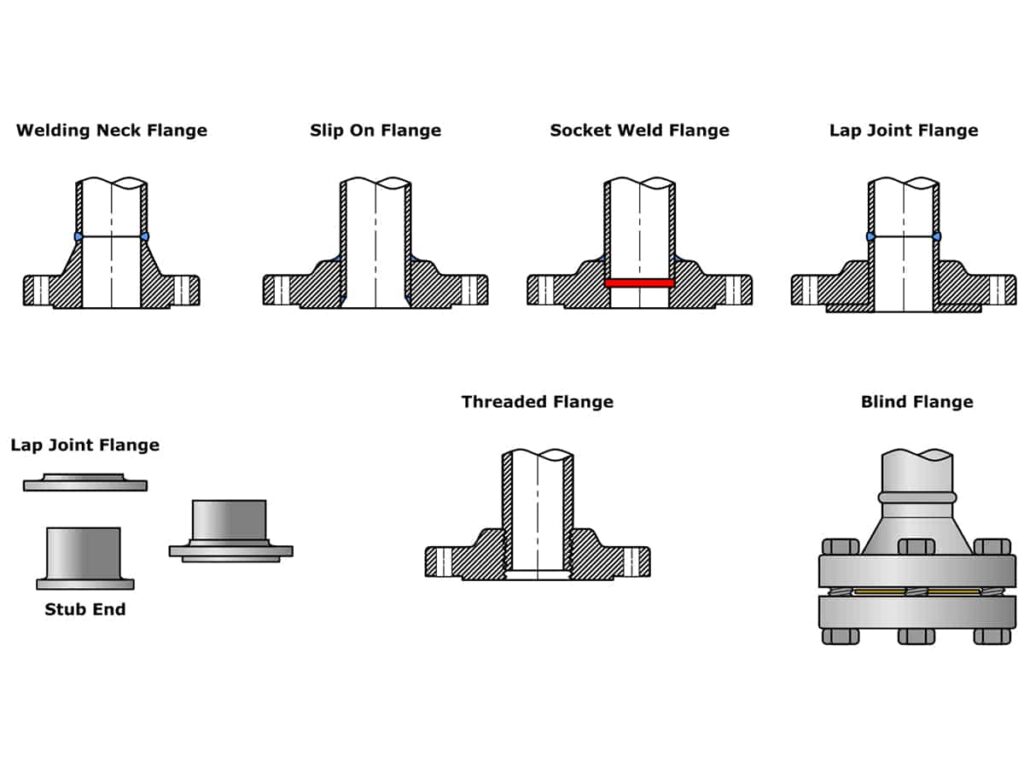

Classification of pipe flanges

Pipe flanges are important components for connecting pipelines and equipment. They can be divided into the following types according to how they are connected to pipelines.

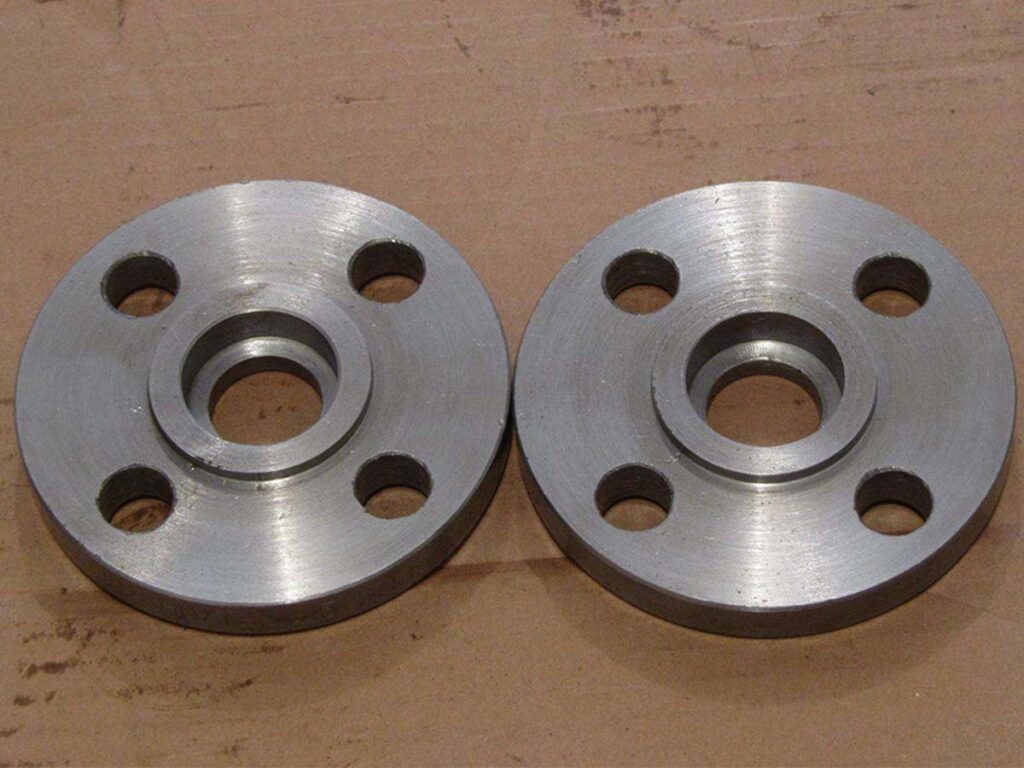

Plate flanges

Plate flange is a commonly used flange connection method. Its structure is relatively simple. Due to its low manufacturing cost, it is widely used in low-pressure, low-temperature, and general medium pipeline systems.

Plate flanges are generally circular in structure, and there are anti-slip grooves on the flange surface to facilitate the tightening of bolts.

Wafer flanges

Wafer flange is also called clamp flange or ring clamp flange. Its structural feature is that a clamp (clamp) device is installed at both ends of the flange, and the two flanges are connected together by rotating bolts.

Wafer flange is widely used in pipeline systems under strong media conditions such as high pressure, high temperature, and corrosion.

Spiral gasket flanges

Spiral rubber gasket flange is a flange connection method that uses rubber gaskets for sealing.

The rubber gaskets used in the flange sealing are made of special materials that are resistant to high temperature, high pressure and corrosion. Spiral rubber gasket flanges are generally used in pipeline systems with high pressure and corrosive media.

Butt-weld flanges

Butt welding flange is to install butt welding rings on both ends of the flange, and connect the two flanges together by butt welding.

Butt welding flange is generally used in pipeline systems with high pressure, high temperature and viscous media.

Ball flanges

Flange ball is a new type of flange, which has a simpler structure than traditional flange and has the advantages of easy disassembly and assembly, reliable sealing, etc.

Flange ball is usually used in pipeline systems under strong media conditions such as high pressure, high temperature, corrosion resistance, etc.

Applications of pipe flanges

In addition to being classified by connection method, pipe flanges can also be classified by parameters such as material and nominal pressure.

Different types of pipe flanges are suitable for different occasions. Here are some common application scenarios.

Stainless steel flanges

Stainless steel flanges are suitable for chemical, petroleum, shipbuilding, metallurgy and pharmaceutical industries.

Carbon steel flanges

Carbon steel flanges are suitable for boilers, pressure vessels, petrochemicals, power plants and shipbuilding.

High-pressure flanges

High-pressure flanges are suitable for power plants, oil, gas and other fields.

Stainless steel butt-weld flanges

Stainless steel butt welding flanges are suitable for food, beverage, pharmaceutical, chemical and other industries.

What types of flanges are used in the petrochemical industry

Flanges connect valves, pipes, pumps and other machinery to form pipeline structures.

Stainless steel pipe flanges are used in a variety of industries and applications, but flange material and design is an important consideration in the petrochemical industry because pipelines need to transport chemicals and other corrosive compounds.

Butt-weld flanges

These flanges are a popular style for use with tapered centers in high pressure environments.

Slip-on flanges

Another option for chemical engineers, and an affordable choice, is a slip-on flange where the flange is slipped onto the pipe and welded to increase pressure and prevent leaks.

Threaded flanges

Threaded flanges can be used in special cases where a flange can be attached to a pipe without welding. These are usually placed on deep wall thickness pipes and are used to create inner pipes.

Blind flanges

Blind flanges are ideal for high pressure applications. Most flanges come without screws and are used to close pipe ends, doors and openings in pressure applications.

Summary

Different types of pipe flanges have different characteristics and application scenarios. Choosing the right flange type can ensure the safety and stability of the pipeline system.

In practical applications, it is necessary to fully understand the characteristics of various flanges to provide a strong guarantee for the normal operation of the pipeline system.

If you are interested in our products, you can contact us and we will send you the product catalog and price list.