High Quality Lap Joint Flange

High Quality Lap Joint Flange

What is flange?

Flange is used in piping systems to connect pipes to equipment and other pipes as well as instrumentation components, special items etc. They provide additional flexibility during assembly, disassembly and maintenance of piping systems.

According to the type of connection of the pipe, there are five basic types of flanges, including slip on flanges, butt welded flanges, threaded flanges, socket welded flanges and lap joint flanges.

What is High Quality lap joint flange?

High quality lap joint flange is one of the popular choice of flange type used in piping systems. It is usually used in the medium temperature and pressure are not high and the medium corrosive occasions.

When the corrosive medium is strong, the part of the flange in contact with the medium (flanging short section) for corrosion resistance of higher materials, such as stainless steel and other materials. On the outside, low grade materials such as carbon steel are used to clamp the flange ring to achieve seal.

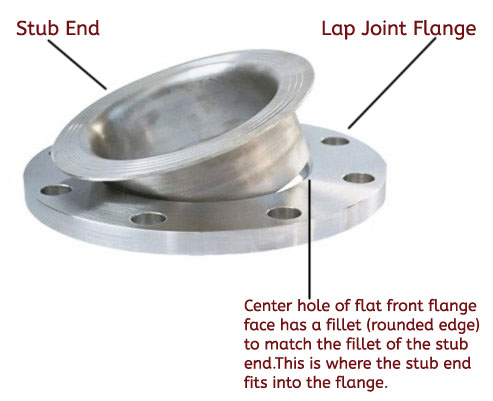

Lap joint flange consists of two parts namely

Lap Joint Stub End : This is butt welded to pipe.

Backing Lap Joint Flange : It slides on the stub end before stub is welded to pipe.

Standard Specification For Lap Joint Flanges

| Dimensions | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc. |

| DIN | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673 |

| BS | BS4504 , BS4504, BS1560, BS10 |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

What material is used for lap joint flanges?

Materials typically used for Lap Joint flanges include a range of stainless steel, carbon steel and other alloy materials. These flanges are available in common dimensions like other flange types, making them easy to integrate into existing piping systems or use with other piping components.

The advantages and disadvantages with the lap joint flange design are:

Advantages:

- Inexpensive.

- Well suited for corrosive applications.

- Requires only a single full penetration butt weld.

- Only the stub end has contact with the process medium.

- It is available in almost all pipe diameters.

- It does not require fillet welding to the plate. This fact decreases installation times and provide further upfront cost savings.

- Free adjustment and rotation flange. It can be easily adjusted to align with the mating flange (the flange can be rotated until the bolt holes align).

- It can be used in systems where frequent disassembly of the flange is required e.g. when cleaning or inspection is required.

- In high corrosion and high erosion processes, piping may have to replaced frequently. In this case, just replace the short end of the flange. The lap joint flange can be reused to save the cost of pipeline replacement.

- It is possible to use a cheaper grade material for the lap joint flange.

Disvantages:

- Due to its abulkier multiple component design, lap joint flanges cannot be used for small size pipes.

- The biggest limitation to lap joint flange usage is pressure ratings.

- Similar to slip on flange, Lap joint flanges cannot be used in high pressure applications. It is necessary to consult piping materials engineers to ascertain viability of lap joint flanges in certain high pressure applications.