How to distinguish the quality of carbon steel pipe

What is carbon steel pipe?

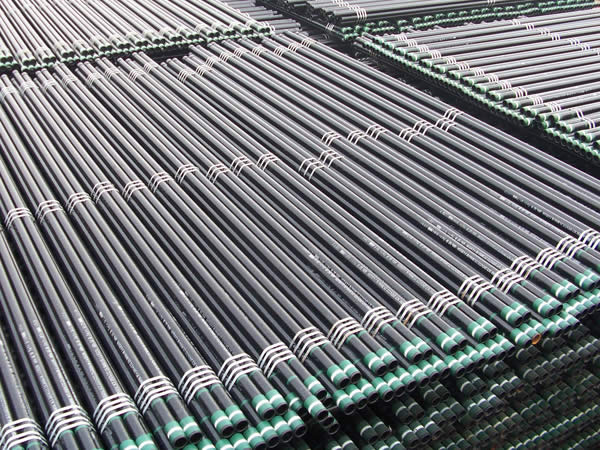

Carbon steel pipe is made of ingot or solid round steel through perforation to make a pipe, and then hot rolled, cold rolled or cold drawn to make. It plays an important role in China’s steel pipe industry.

Carbon steel pipe is a kind of steel pipe alloy. And the common carbon steel pipe in production is generally divided into high, medium and low carbon three categories. High-carbon steel pipes have the highest carbon content, generally greater than 0.6 percent. But we know that the higher the carbon content, the greater the brittleness. So high-carbon steel pipes are generally not used for industrial production. Medium carbon steel pipe is generally 0.25 to 0.6 percent, such steel pipe hardness is moderate, more widely used. The carbon content of low carbon steel pipe is below 0.25 percent, and this kind of carbon steel pipe and ordinary steel pipe are basically not much different, so it is more common in industrial uses.

How to distinguish the quality of steel pipe?

1. Carefully observe the surface of the steel pipe for folding.

If there are many different lines on the surface of the steel pipe, it means that the product is an inferior product. In the production process, if the manufacturer chooses to reduce the amount of material used in order to pursue production efficiency, it will lead to the broken line phenomenon when the steel pipe is rolled. Once the steel pipe is broken, it is easy to crack during later bending.

2. Carefully observe the steel pipe surface is not pocked.

The surface of the steel pipe has a pockmarked surface, it means that the product is an inferior product. The reason why the steel pipe has pockmarked surface is generally because the rolling groove is worn too seriously, resulting in irregular problems on the surface of the steel pipe. Many bad manufacturers in order to pursue interests, often appear the phenomenon of excessive rolling groove.

3. Look carefully at the surface of the steel pipe for cracks.

If there are cracks on the surface of the steel pipe, it means that the product is an inferior product. The reason why the steel pipe has cracks is generally because the manufacturer uses adobe in the production of the steel pipe. The porosity of the adobe is generally more, and it is easy to crack during the cooling process. When it is rolled, it will naturally leave cracks.

4. Look closely at the surface of the steel pipe for scratches.

If the manufacturer’s production equipment is very simple, it is easy to appear burrs and scratch the surface of the steel pipe. The deep scratch on the surface of the steel pipe will lead to a reduction in the strength of the steel pipe, which will affect the performance and service life of the steel pipe.

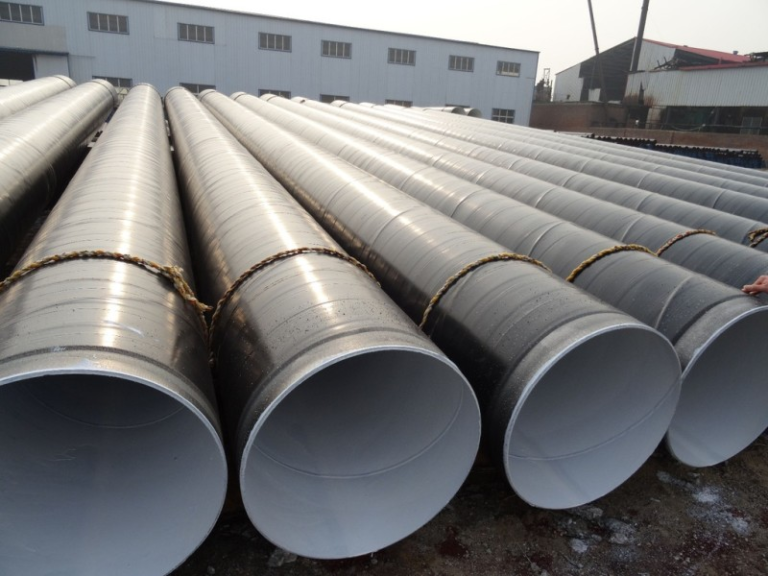

Why choose us to buy elbow ?

As a leading manufacturer, distributor and exporter of steel pipes, fittings and flanges in the world. Metleader has been exporting products with big quantity to many countries and areas. Our company have been passed several certificates including ISO9001: 2008, ISO14001, OHSAS18001, CE certificate, one member of supplier system of Sinopec, and CNPC.

In situations like high pressure, temperature, and corrosion, our steel pipes are perfectly suitable. We will provide the best service to our customers. welcome your inquiry timely salesmanager@metleader.com .