How to measuring steel pipe elbow radius

How to measuring steel pipe elbow radius?

Measuring steel pipe elbow radius first we know what is steel pipe elbow radius. It means is center high,such as erect the elbow of 90 degrees,One head leaned against the wall. Then draw lines. From the outermost side of the elbow, draw up to half of the upper caliber. This is the center distance.

Elbow bending radius: (1) 45 degree duct elbow bending radius is the bending radius multiplied by 0.785; 90 degree is the bending radius multiplied by 1.57;

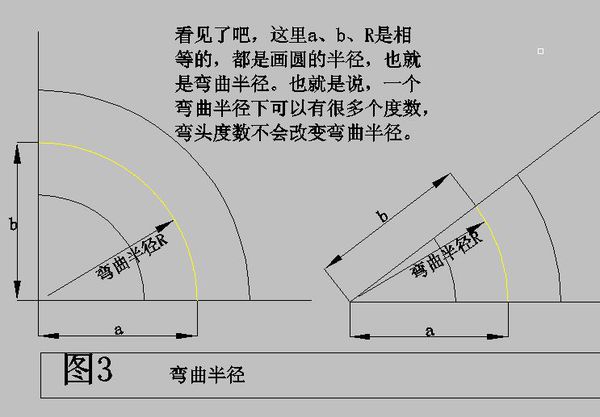

(2) concept: the bending radius R of pipe elbow is the radius of curvature corresponding to the central line of this bend. Generally determined by the multiple of the pipe diameter. For example, the hot bending elbow is usually one to two times curved, and the bending pipe is usually three to four times bent.

External diameter R = 100, turning radius 20 * R = 2000mm. If the actual cable turns 90 degree, the power cable should be strictly prevented from twisting and excessive bending during transportation, installation or operation. The ratio of the minimum allowable bending radius of the cable to the cable’s external diameter should not exceed the minimum allowable bending half of the cable in Table 1. The ratio of the diameter to the outer diameter of the cable.

Ring volume = 2X3.14X3.14 (r ^ 2) R R – Ring radius R – Ring revolving radius hollow tube ring volume = 2X3.14X3.14 ((r ^ 2) – (r’^ 2)) R R’- Ring radius 90, 60, 45 degrees elbow (elbow tube) volume is the corresponding hollow tube ring volume of 1/4, 1/6, 1/8. The density of steel is calculated by weight of 7.85 kg / cubic meter, density X volume = weight (mass).