Long radius elbow vs short radius elbow, the truth you need to know

Contents

Differences between short radius elbows and long radius elbows

Application scenarios of short radius elbows and long radius elbows

Interchangeability of short radius elbows and long radius elbows

How to choose elbow dimensions

There are two types of elbow radius: short radius elbow and long radius elbow.

Today we will talk about the difference between these two types of elbows and how to choose them.

If you are interested in our products, you can contact us at any time to get a more professional answer.

Differences between short radius elbows and long radius elbows

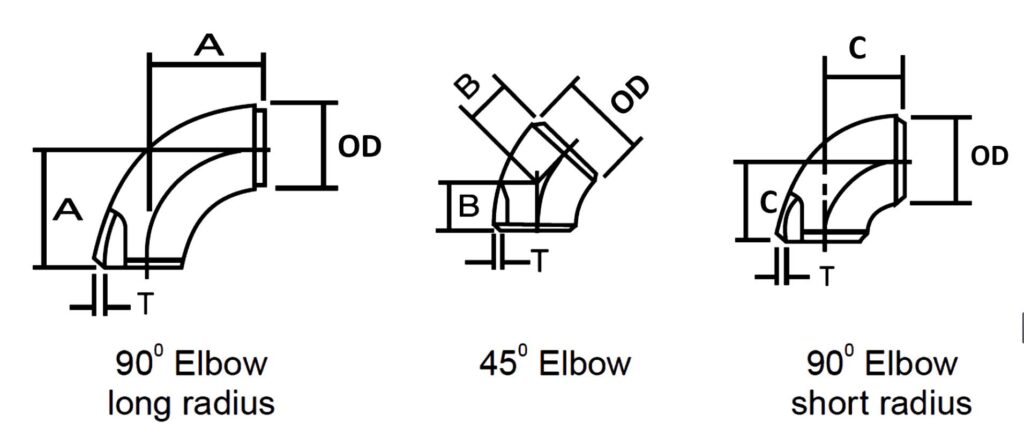

Short radius elbows and long radius elbows are both commonly used pipe fittings in piping systems. The difference between the two is the curvature radius of the elbow.

The curvature radius of the short radius elbow is 1 times the pipe diameter, while the curvature radius of the long radius elbow is 1.5 times or 2 times the pipe diameter.

Application scenarios of short radius elbows and long radius elbows

Short radius elbows are mainly used in situations where straight pipes are required to bend, such as changing direction at right-angle bends, requiring multiple bends in the pipeline route, or bypassing obstacles.

Long radius elbows are more often used in situations where the flow state of the fluid in the pipeline needs to be kept stable, such as situations where a larger bending radius is required or resistance loss is reduced, and are often used in pipelines that transport media with higher pressures.

Interchangeability of short radius elbows and long radius elbows

Since the curvature radius of the short radius elbow is small and the bending angle is large, the liquid flow in the pipeline will produce a large resistance loss when passing through it; in contrast, the curvature radius of the long radius elbow is large, the bending angle is small, and the resistance loss of the liquid flow is relatively small.

Therefore, under the premise of ensuring the normal operation of the pipeline, short radius elbows and long radius elbows are generally not replaceable.

However, in some cases, such as when the pressure in the pipeline is low and the flow rate is low, you may consider using a short radius elbow to replace a long radius elbow to save costs.

Long radius elbow dimensions

The radius of a long radius elbow is generally 1.5D of the pipe diameter, that is, the distance from the pipe bending center to the elbow surface is equal to 1.5 times the elbow diameter.

Compared with short radius elbows, long radius elbows have a slower bending degree and are more suitable for situations where the pipe needs to turn over a large range or requires functional construction.

The size parameters of long radius elbows are similar to those of short radius elbows, but the pipe diameter is generally larger.

Short radius elbow dimensions

The radius of a short radius elbow is generally 1.0D of the pipe diameter, that is, the distance from the pipe bending center to the elbow surface is equal to twice the elbow diameter.

Common short radius elbows include 90-degree, 60-degree, 45-degree, 30-degree and 15-degree elbows.

Among them, the 90-degree short radius elbow is the most common and is suitable for situations where the pipeline needs to make a sharp turn.

How to choose elbow dimensions

The selection of elbow size needs to take into account the actual situation of the pipeline, including factors such as pipeline material, working pressure, temperature, flow rate, etc.

Generally speaking, short radius elbows are used in situations where sharp turns are required, while long radius elbows are used in situations where large turns or functional structures are required.

At the same time, the corresponding pipe diameter and elbow angle need to be selected according to factors such as the size, angle and flow rate of the pipeline to ensure the smooth operation, safety and stability of the pipeline system.

Practical suggestions

When choosing a short radius elbow:

- The pressure and flow rate in the pipeline are small and the viscosity is not high;

- The site is small and the pipeline route needs to be bent sharply;

- The right-angle turn where the pipeline direction needs to be changed.

When choosing a long radius elbow:

- The pressure and flow rate in the pipeline are large and the viscosity is large;

- The flow state of the medium in the pipeline is required to be stable;

- The resistance coefficient is required to be small to prevent excessive pressure drop.

Summary

In the design or maintenance of the pipeline system, the actual situation should be considered comprehensively and the appropriate type of pipe fittings should be selected to ensure the normal operation of the pipeline system.

If you also need this kind of elbow in your system, you can contact us to obtain the product catalog and price.