Let you understand the characteristics of precision seamless pipes

What is the material of precision seamless pipe?

What is the chemical composition of precision seamless pipes?

What is the production process of precision seamless pipes?

What are the advantages of precision seamless pipes

What are the characteristics of precision seamless pipes?

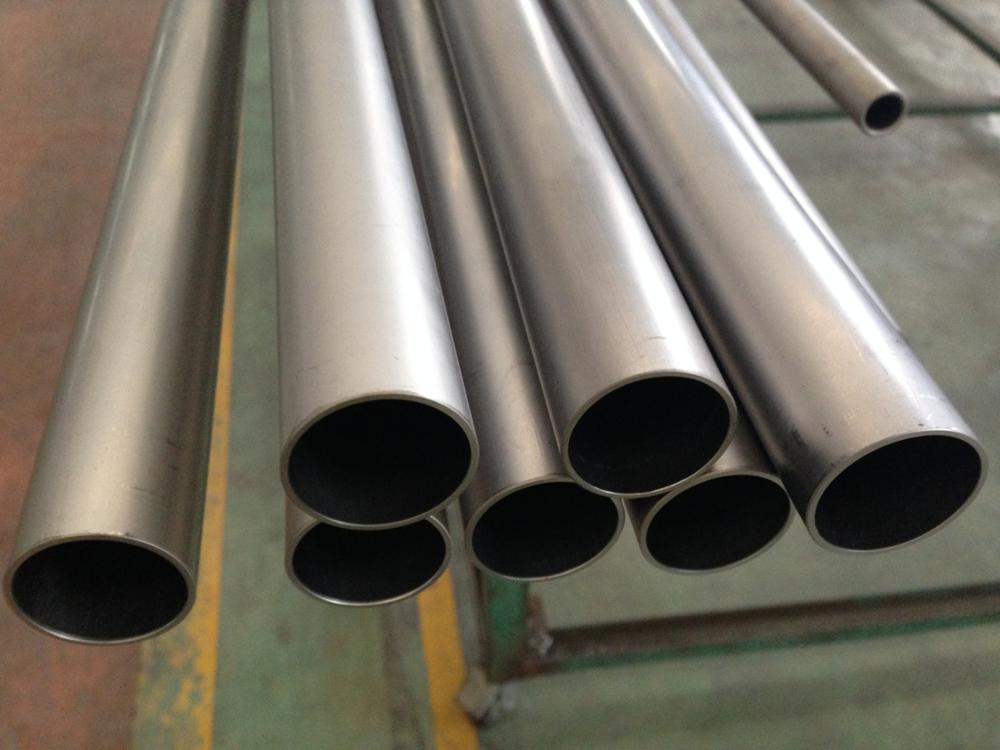

Precision seamless pipe is a high-precision steel pipe material processed by cold drawing or hot rolling.

The surface finish of the inner and outer diameters of precision steel pipes is high, and customers can use them directly without processing; while ordinary seamless steel pipes require customers to lathe, polish, etc.

What is the material of precision seamless pipe?

Commonly used materials for precision seamless pipes are 10#, 20#, 35#, and 45#.

There are many materials that can be produced. As long as steel is not too hard, it can basically be produced according to needs. Such as: 10#, 35#, 16Mn, 40Cr

What is the chemical composition of precision seamless pipes?

The chemical composition of commonly used 20# and 45# precision seamless pipes is shown in the table below:

| Trademark | chemical composition% | |||||

| – | C | Si | Mn | S | P | Cr |

| 10# | 0.07-0.13 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | – |

| 20# | 0.17-0.23 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | – |

| 35# | 0.32-0.39 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | – |

| 45# | 0.42-0.50 | 0.17-0.37 | 0.50-0.80 | ≤0.035 | ≤0.035 | – |

| 40Cr | 0.37-0.44 | 0.17-0.37 | 0.50-0.80 | ≤0.035 | ≤0.035 | 0.08-1.10 |

What is the production process of precision seamless pipes?

Precision seamless pipes are usually produced by cold rolling.

The specific process is as follows:

Round steel → perforation → pickling → cold rolling → saw → bundling

Seamless pipe → pickling → cold rolling → saw → bundling

What are the advantages of precision seamless pipes

High precision, which saves the loss during mechanical processing of user materials.

Multiple specifications and wide range of applications.

The cold-rolled finished product has high precision, good surface quality and good straightness.

The inner diameter of the steel pipe can be made into a hexagonal shape.

The performance of steel pipes is superior and the metal is denser.

What are the characteristics of precision seamless pipes?

There is no oxide layer on the inner and outer walls of the steel pipe, it can withstand high pressure, no leakage, high precision, high smoothness, no deformation in cold bending, no cracks in flaring and flattening, and anti-rust treatment on the surface.

It is widely used in steel pipes for hydraulic systems, steel pipes for injection molding machines, Steel pipes for hydraulic machines, steel pipes for shipbuilding, EVA foam hydraulic machinery, steel pipes for precision hydraulic cutting machines, shoemaking machinery, hydraulic equipment, high-pressure oil pipes, hydraulic oil pipes, ferrule joints, steel pipe joints, rubber machinery, forging machinery, Die-casting machinery, engineering machinery, high-pressure steel pipes for concrete pump trucks, sanitation vehicles, automobile industry, shipbuilding industry, metal processing, military industry, diesel engines, internal combustion engines, air compressors, construction machinery, agricultural and forestry machinery, etc., can completely replace the same standard Imported seamless steel pipes.

Classification

Precision seamless steel pipe, precision hydraulic seamless steel pipe, cold drawn precision seamless steel pipe, cold rolled precision seamless steel pipe, high precision seamless steel pipe, precision bright seamless steel pipe.

Main varieties

DIN/EN series high-precision bright seamless steel pipes, special steel pipes for hydraulic systems, special steel pipes for automobile manufacturing

Main criteria

DIN2391, DIN2445, EN10305, GB/T 3639 GB 8713……….

main material

ST35(E235), ST37, ST45(E255), ST52(E355), 10#, 20#, 35#, 45#……

Main delivery status

NBK(+N)GBK(+A)BK(+C)BKW(+LC)BKS(+SR)