Quality standards and specifications for reducer fittings

Contents

- What is a reducer

- Things to note when choosing a reducer

- Things to note when using a reducer correctly

- Common materials for reducers

- Things to note when purchasing a reducer

- Specifications of reducers

- Summary

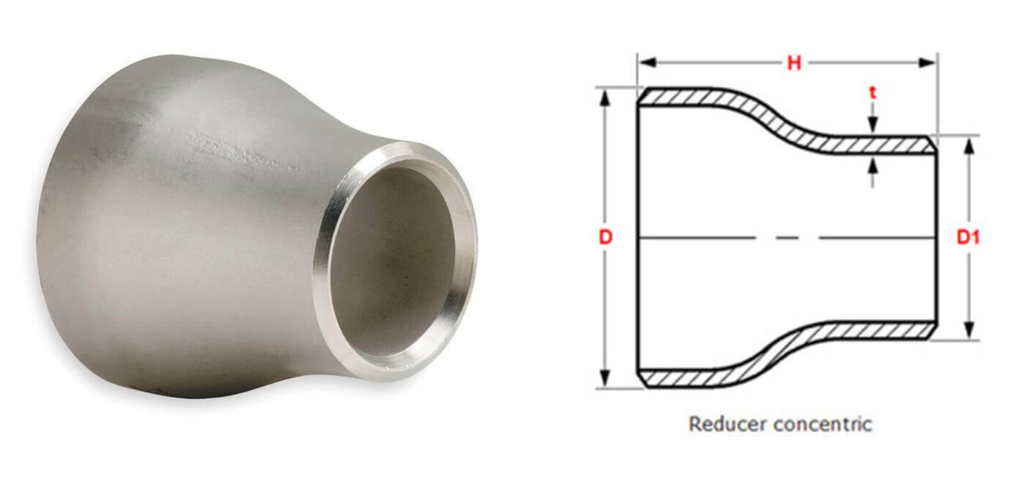

A reducer is a connector installed on a pipe, used to connect different pipe diameters or two pipes of different materials.

According to the connection method, reducers can be divided into different types such as insert type, flange type, and lap type. Among them, insert type reducers can be divided into two types: elastic seal and sliding seal.

What is a reducer

The big and small heads refer to the joints used to connect pipes of different diameters in the pipeline system. Generally, there are two types: big heads and small heads.

The big heads generally refer to pipes with larger outer diameters, while the small heads refer to pipes with smaller outer diameters.

Things to note when choosing a reducer

- Material: The main materials used for reducers are cast steel, stainless steel, copper, etc. Different materials are suitable for different working environments and pressure requirements. The appropriate material should be selected according to specific needs.

- Size: The size of the reducer must match the diameter of the pipe in the pipeline system, otherwise it will affect the working efficiency of the pipeline system. The reducer of the appropriate size should be selected according to the actual situation.

- Tooth shape: The tooth shape of the reducer must match the connection port of the pipe, otherwise there will be air leakage, seepage, etc., and may cause accidents. It should be ensured that the selected reducer tooth shape matches the pipe connection port.

- Quality standards: The quality standards of reducers mainly include requirements in terms of materials, size, tooth shape, etc. Products that meet relevant standards should be selected, and attention should be paid to the production qualification certification and quality inspection standards of regular manufacturers.

Things to note when using a reducer correctly

- Correct installation: The installation of the reducer must comply with relevant installation standards and specifications, and should avoid damage or affecting the tightness of the connector.

- Appropriate torque: When installing the reducer, the wrench needs to be used to give the appropriate torque according to the requirements to ensure the tightness of the connection.

- Prevent overuse: In order to avoid fatigue damage to the reducer, excessive use and frequent and repeated disassembly should be avoided during use.

- Regular inspection: In order to ensure the safety and stability of the connection, the connection parts of the reducer should be regularly checked for leakage and other abnormal conditions, and timely measures should be taken to deal with them.

Common materials for reducers

Common materials for reducers include carbon steel, stainless steel, alloy steel, etc.

When using, it is necessary to select the appropriate material according to specific conditions such as medium, temperature, pressure, etc.

Things to note when purchasing a reducer

- Determine the connection method: Select the appropriate connection method to ensure that the pipeline connection is firm and well sealed.

- Determine the material: Select the appropriate material according to the medium, temperature, pressure and other conditions.

- Determine the specification: Select the appropriate specification according to the actual use requirements to ensure the quality and stability of the pipeline connection.

- Pay attention to the installation: Strictly follow the operating requirements during the installation process to prevent problems caused by improper installation.

Specifications of reducers

The national standard specifies various sizes and specifications of reducers, including parameters such as diameter (DN), wall thickness (S), and length (L).

For example, the specifications of flange reducers range from DN15 to DN2200, the wall thickness ranges from 1.6 to 24.0 mm, and the length ranges from 60 to 200 mm.

The sizes of plug-in reducers are more flexible and can be customized according to needs.

Summary

As an important part of pipeline connection, reducers should be selected with appropriate materials, sizes and thread shapes according to specific needs before use, and products that meet relevant standards should be selected.

When installing and using, attention should be paid to correct installation, giving appropriate torque, avoiding excessive use and regular inspection to ensure work safety and quality.