Introduction to seamless steel pipe

Introduction OF The seamless steel pipes development history:

Seamless steel pipe production has a history of nearly 100 years.

In 1885, the German Manisman brothers first invented the two-high skew piercing machine. And invented the periodic pipe roller in 1891. Then in 1903, the Swiss R.C.Stiefel invented the automatic pipe rolling machine, and later appeared the continuous pipe rolling machine and pipe pushing machine and other extension machines, beginning to form the modern seamless steel pipes industry.

With the development of modern seamless steel pipe industry, in the 1930s, the variety quality of steel pipes were improved by adopting three-high pipe rolling machine, extruding machine and periodic cold pipe rolling machine. In the 1960s, due to the improvement of continuous pipe rolling machine and the emergence of three-roll punching machine, especially the successful application of tension reducing machine and continuous casting billet, Improve the efficiency and enhance the competitiveness of seamless pipe and welded pipe In the 70’s, seamless and welded pipes are abreast, the world steel pipe output at a rate of more than 5% per year.

Since 1953, China has attached great importance to the development of seamless steel pipe industry, and has initially formed a production system for rolling various large, medium and small pipes.

Use and classification of seamless steel pipes:

Usage:

It is a kind of economic cross-section steel that has a very important position in the national economy. It is widely used in petroleum, chemical industry, boiler, power station, ship, machinery manufacturing, automobile, aerospace, construction and other sectors.

Classification:

- Section shape: Circular section pipe and special-shaped section pipe.

- Material: Carbon steel pipe, alloy steel pipe, stainless steel pipe.

- Connection mode: Threaded connection pipe, welded pipe.

- Production method: Hot rolling (extrusion, top, expansion) pipe, cold rolling (drawing) pipe.

- By use: Boiler pipe, oil well pipe, pipeline pipe, structure pipe, chemical fertilizer pipe……

production process:

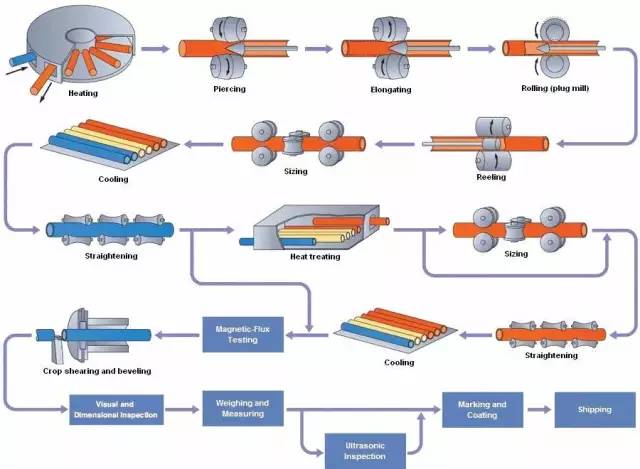

1.Main production process (main inspection process) of hot rolled seamless steel pipes:

Preparation and inspection of pipe blank → Heating of pipe blank → Perforation → Rolling of pipe → Reheating of pipe in waste → Fixing (reducing) diameter → Heat treatment → Straightening of finished pipe → Finishing → Inspection (non-destructive, physical and chemical, table inspection) → Storage.

2. Cold rolled (drawing) seamless steel pipes main production process:

Blank preparation → Pickling lubrication → Cold rolling (drawing) → Heat treatment → Straightening → Finishing → Inspection.

The production process flow chart of hot-rolled seamless steel pipes: