An article to let you know about seamless steel pipes

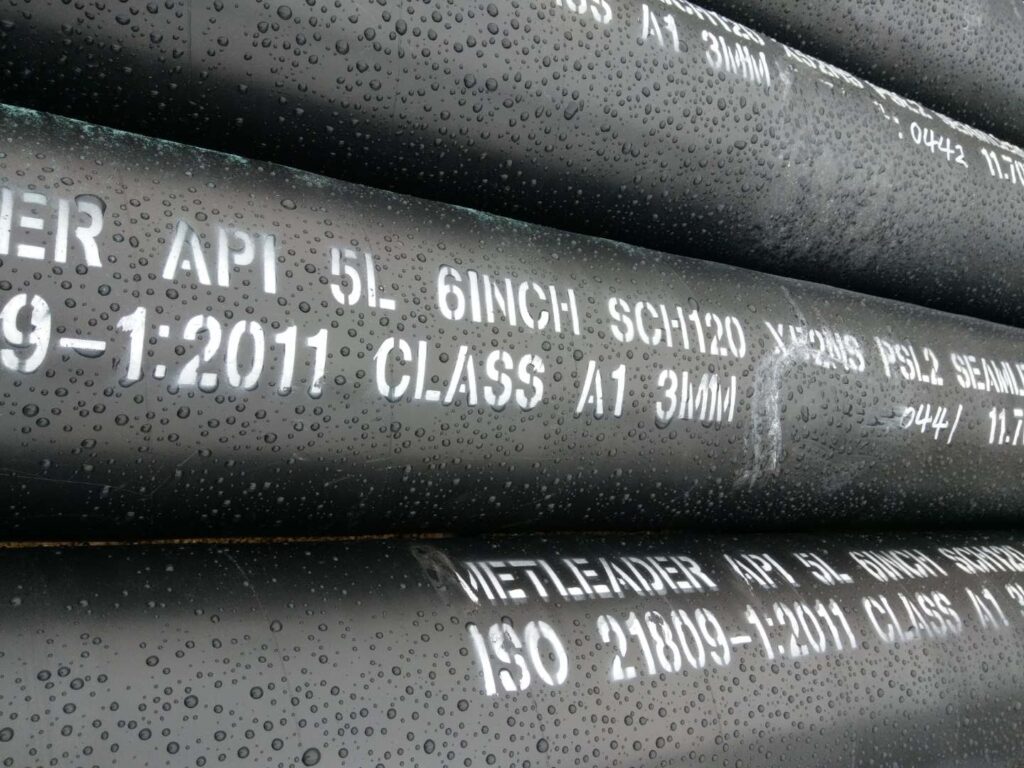

Seamless steel pipe

Seamless steel pipe is the pipe with the largest usage volume and the most varieties and specifications among industrial pipes.

Basically divided into:

There are two categories: seamless steel pipes for fluid transportation and special-purpose seamless steel pipes.

The former is a steel pipe commonly used in process pipelines, while the latter is a special steel pipe for boilers, cracking furnace pipes and steel pipes for heat exchangers.

According to material, it can be divided into:

Carbon seamless steel pipe, chromium-molybdenum seamless steel pipe and stainless, acid-resistant seamless steel pipe.

According to the nominal pressure, it can be divided into:

There are three categories: low pressure (0≤1.0MPa), medium pressure (1.0<10MPa=, high pressure (≥10MPa)).

Carbon seamless steel pipe

Commonly used manufacturing materials are No. 10, No. 20, and 16Mn steel.

Its specification range is: hot-rolled outer diameter φ32~630mm, cold-drawn outer diameter φ6~200mm, single tube length 4~12m, and the allowable operating temperature is -40~450℃.

It is widely used to transport various media that are non-corrosive to steel, such as steam, oxygen, compressed air, oil and oil and gas.

Low alloy steel seamless steel pipe

Refers to alloy steel pipes containing a certain proportion of alloy elements.

Usually divided into two types:

One is a low-alloy steel pipe containing manganese, called ordinary low-alloy steel pipe, such as 16Mn, 15MnV, etc.; the other is a low-alloy steel pipe containing chromium, molybdenum and other elements, called chromium-molybdenum steel pipe.

Commonly used ones include 12CrMo, 15CrMo, 12Cr2Mo, 1Cr5Mo, etc.

Their specifications range from φ10 to φ273mm in outer diameter, 4 to 12m in length of a single pipe, and the applicable temperature range of chromium-molybdenum steel pipes is -40 to 550°C.

Low-alloy seamless steel pipes are mostly used to transport various higher-temperature oil products, oil and gas, less corrosive salt water, low-concentration organic acids, etc.

Stainless acid-resistant seamless steel pipe

According to the different contents of various metals such as chromium, nickel and titanium, there are many varieties, including Cr13, 00Cr17Ni14Mo2, 1Cr18Ni12Mo2Ti, 1Cr18Ni9Ti, etc.

The most commonly used steel grade is 1Cr18Ni9Ti, which is commonly represented by the simplified material code 18-8 on construction drawings. The applicable temperature range is -196~700°C.

In chemical production, it is used to transport various highly corrosive media, such as nitric acid, acetic acid and urea.

High pressure seamless steel pipe

Its manufacturing material is basically the same as the above-mentioned seamless steel pipe, except that the pipe wall is thicker than the medium and low-pressure seamless steel pipe, with the thickest pipe wall reaching 40mm.

For example, the specifications of high-pressure seamless steel pipes for fertilizer equipment are φ14×4(mm)~273×40(mm), the length of a single pipe is 4~12m, the applicable pressure range is 10~32MPa, and the working temperature is -40~400℃.

In petrochemical equipment, the above high-pressure seamless steel pipes are used to transport raw material gas, hydrogen nitrogen, synthesis gas, water vapor, high-pressure condensed water and other media.

Low temperature steel pipe

It is used more in the cold area of imported engineering projects. Its material grades are STPL-39 and STPL-46, and the working temperature can reach -105°C.

Low-temperature steel pipes are divided into two types: seamless steel pipes and seamed steel pipes.

The nominal diameter of seamless low-temperature steel pipes is 15 to 400mm, and the wall thickness is the same as that of carbon steel pipes; the nominal diameter of seamed low-temperature steel pipes is 400 to 1100mm, and the wall thickness is 6 to 10mm.

The standard length of root canal is 6m.

It is suitable for transporting various non-corrosive low-temperature medium pipelines.

At present, there is no mass production of steel pipes corresponding to this standard in China.

Pipe fittings

Pipe fittings are required to change the direction, elevation or pipe diameter in the piping system, as well as to lead branch pipes from the main pipe.

Since the shapes of pipe systems vary from simple to traditional, there are many types of pipe fittings.

Commonly used pipe fittings include elbows, tees, reducers, pipe joints, pipe caps, etc.