Service life of anticorrosive steel pipe

Service life of anticorrosive steel pipe

The service life of anti-corrosion steel pipe is the key to anti-corrosion treatment!

Steel pipe corrosion is a common problem, so in order to avoid or reduce steel pipe corrosion, it is necessary to take anti-corrosion measures. Under normal circumstances, the anti-corrosion method of steel pipe is mainly coated with preservatives, or rust removal metal pipe surface uniform, dense paint, or uniform, dense paint on the inner wall of the steel pipe. Although some steel pipes have been treated with corrosion protection, it does not mean that they will last for many years. So, what are the factors that affect the service life of corrosion resistant steel pipes? Which factor is the key? How can we fix it?

Good anticorrosive materials and methods:

In order to extend the service life of anticorrosive steel pipe, the service life of anticorrosive steel pipe largely depends on the anticorrosive method of steel pipe, therefore, it is necessary to use good anticorrosive materials and anticorrosive methods, specifically divided into two points as follows:

1.To prolong the service life of anticorrosive steel pipe, we must start with the selection of anticorrosive materials.

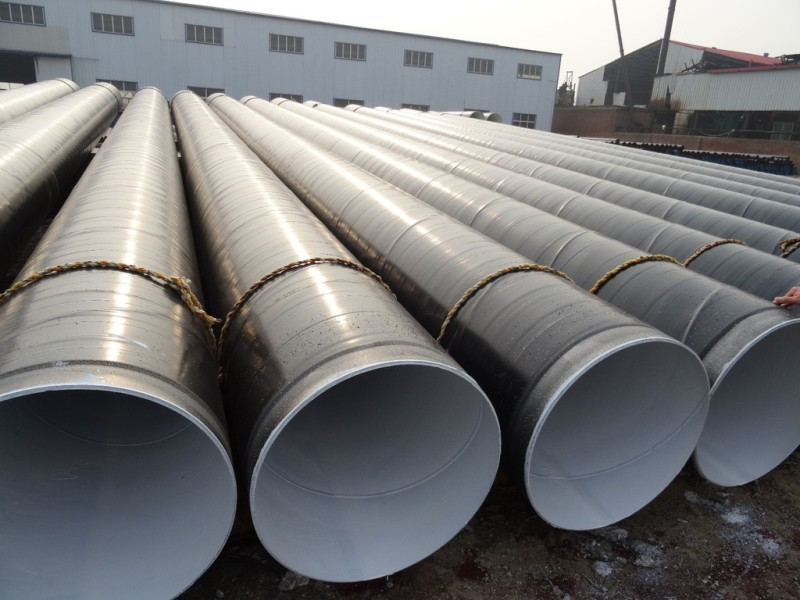

The main materials used in anticorrosive coatings are coal tar enamel paint, which makes pipes better protected. However, these materials also have many disadvantages, which limit their range of application. However, fortunately, with the development of society, the emergence of epoxy resin anticorrosive melt powder coating has led to the rapid development of pipeline protection technology.

After all, the main advantages of epoxy anticorrosive molten powder coating are good corrosion resistance, good mechanical properties and strong resistance to cathodic stripping. The process is a combination of the anticorrosive structure of single-layer heavy-duty epoxy powder coating, double-layer heavy-duty epoxy powder coating and three-layer heavy-duty epoxy powder coating, which can protect the steel pipe pile to the greatest extent and mitigate the corrosion of the steel pipe pile. Anticorrosive tube and lined plastic tube were obtained effectively.

It has been proved that the protection of steel pipe is accurate, scientific and suitable for buried ground. Anticorrosive treatment of underground or submarine pipelines.

2. Correct anti-corrosion treatment to start with, to prolong the service life of anti-corrosion steel pipe

In the anti-corrosion treatment of steel pipes, attention should be paid to the following points: surface pretreatment, the metal surface of the pressure steel pipe, the outer wall of the spray to remove rust, and construction in a relatively sealed room. For a large number of derusting pipes, rust remover or machinery can be used. Mechanical derusting through sand blasting and other methods can improve labor efficiency and reduce human and air pollution. When high anticorrosive quality is required or the inner and outer walls of the pipe have rusted, a chemical rust remover can be used to effectively remove oxides from the pipe, inner and outer surfaces.

First, paint the inner wall of the steel pipe. Then, paint the inner wall of the steel pipe in time after the pretreatment quality is qualified; Finally, paint should be applied in strict accordance with the paint manufacturer’s instructions; The coating should be completed within 4 hours of full sun or not too wet, and the spray painting should be completed within 8 hours.

Steel pipe is not only used to transport fluids and powdery solids, exchange heat, and make machine parts and containers, it is also an economic steel. First, using steel pipe to make building structure grid, pillar and mechanical support, can reduce weight, save 20~40% metal, and can realize the factory mechanized construction. Second, using steel pipe to make highway bridge can not only save steel, simplify construction, but also greatly reduce the area of protective coating, save investment and maintenance costs.