Socket welding flange: RFvsMFMvsTGvsRJ

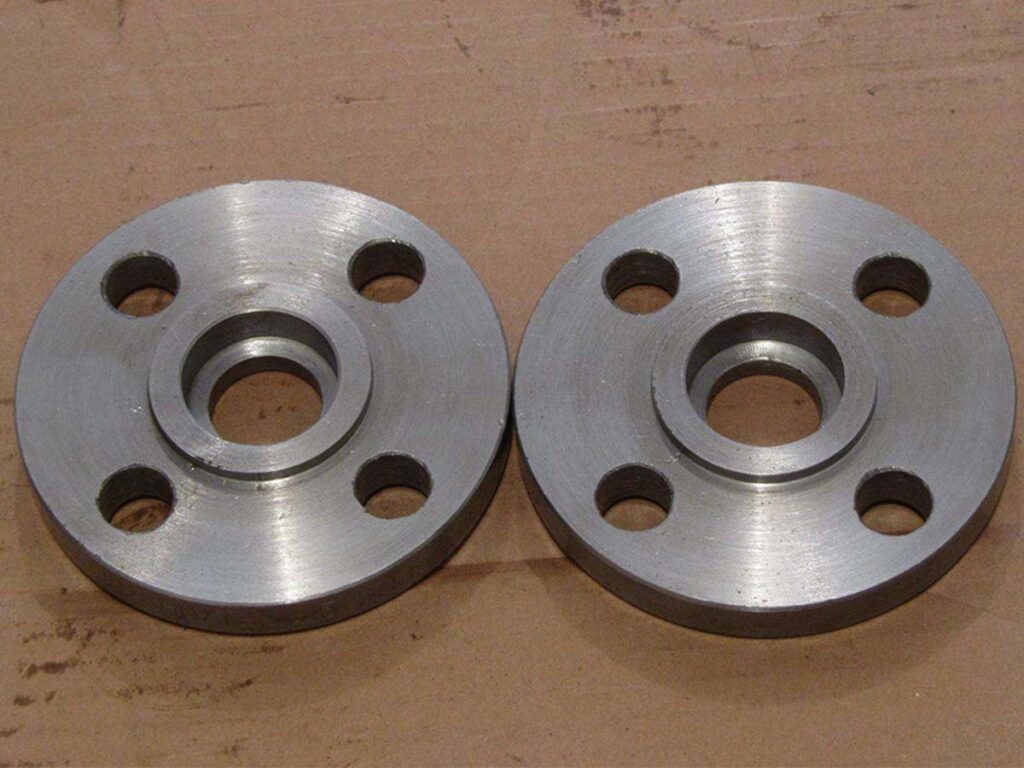

Socket welding flange refers to a flange in which the end of the pipe is inserted into the flange ring step and welded to the pipe end.

There are two types: with neck and without neck.

The flange with neck tube has good rigidity, small welding deformation and good sealing performance.

It can be used in situations where the pressure is 1.0~10.0MPa.

Type B flange for containers is also a socket welding flange and is used in situations with high sealing requirements. During design, the socket welding flange can be calibrated as an integral flange.

| Factor | Raised Face (RF) | Male and Female Face (M&F) | Tongue and Groove (TG) | Ring Joint (RJ) |

|---|---|---|---|---|

| Ease of Installation | – Relatively easy to install. | – Requires precision during alignment. | – Requires precise alignment of tongue and groove. | – Requires careful alignment for optimal sealing. |

| Sealing Effectiveness | – Good sealing effectiveness for moderate pressures. | – Effective sealing due to male and female face contact. | – Effective when tongue and groove are properly aligned. | – Excellent sealing in high-pressure applications. |

| Versatility | – Versatile for various applications. | – Versatile but may require specific gaskets. | – Versatile for moderate pressure applications. | – Commonly used in high-pressure and extreme temperature applications. |

| Pressure Rating | – Suitable for moderate to high-pressure systems. | – Adequate for various pressure applications. | – Suitable for moderate pressure applications. | – Excellent for high-pressure and extreme temperature conditions. |

| Temperature Range | – Suitable for a broad temperature range. | – Appropriate for a wide temperature range. | – Limited by gasket material and flange design. | – Excellent for extreme temperature conditions. |

| Maintenance and Inspection | – Visual inspection for leaks is relatively easy. | – Visual inspection is more challenging. | – Inspection may be more difficult due to tongue and groove. | – Requires detailed inspection due to the ring gasket. |

| Gasket Type | – Typically uses flat gaskets. | – Compatible with flat or raised face gaskets. | – Suitable for ring gaskets. | – Often used with ring gaskets. |

| Specific Applications | – Common in general-purpose applications. | – Used in various applications with specific sealing requirements. | – Common in low to moderate-pressure applications. | – Commonly used in high-pressure and extreme temperature applications. |

There are four main types of sealing surfaces for socket welding flanges:

raised surface (RF), concave and convex surface (MFM), tongue and groove surface (TG), and ring connection surface (RJ).

Today we will mainly talk about the differences, advantages and disadvantages between them.

| Aspect | Raised Face (RF) | Male and Female Face (M&F) | Tongue and Groove (TG) | Ring Joint (RJ) |

|---|---|---|---|---|

| Advantages | – Easy to machine and install. | – Improved alignment during assembly. | – Offers good sealing performance. | – Excellent sealing in high-pressure systems. |

| – Suitable for various gasket materials. | – Versatile, compatible with different gaskets. | – Suitable for moderate pressure applications. | – Suitable for extreme temperature conditions. | |

| – Versatile for various applications. | – Effective sealing due to male and female face contact. | – Versatile for moderate pressure applications. | – Compatible with various pressure and temperature conditions. | |

| – Improved alignment benefits various applications. | – Improved alignment benefits various applications. | – Used in critical applications with high-pressure conditions. | ||

| Disadvantages | – Prone to leakage due to limited compression. | – Requires precision during installation. | – May require specific gaskets for optimal sealing. | – Complex installation and maintenance. |

| – Less effective in high-pressure applications. | – May require specific gaskets for optimal sealing. | – Complex installation and maintenance. | – Requires careful machining and alignment. | |

| – May require precise alignment during assembly. | – May require specific gaskets for optimal sealing. | – Requires alignment of tongue and groove. | – May require specific gaskets for optimal sealing. | |

| Specific Characteristics | – Provides additional compression for gaskets. | – Improved alignment during assembly. | – Requires precise alignment of tongue and groove. | – Groove with a metal ring on the flange face. |

| – Suitable for moderate to high-pressure systems. | – Common in low to moderate-pressure applications. | – May require specific gaskets for optimal sealing. | – Excellent for high-pressure and extreme temperature conditions. | |

| – Visual inspection for leaks is relatively easy. | – Visual inspection is more challenging. | – Inspection may be more difficult due to tongue and groove. | – Requires detailed inspection due to the ring gasket. |