Let you know the characteristics of socket welding flange

Standard for socket weld flanges

Application of socket welding flange

Material of socket welding flange

Processing method of socket welding flange

Advantages and Disadvantages of Socket Weld Flange

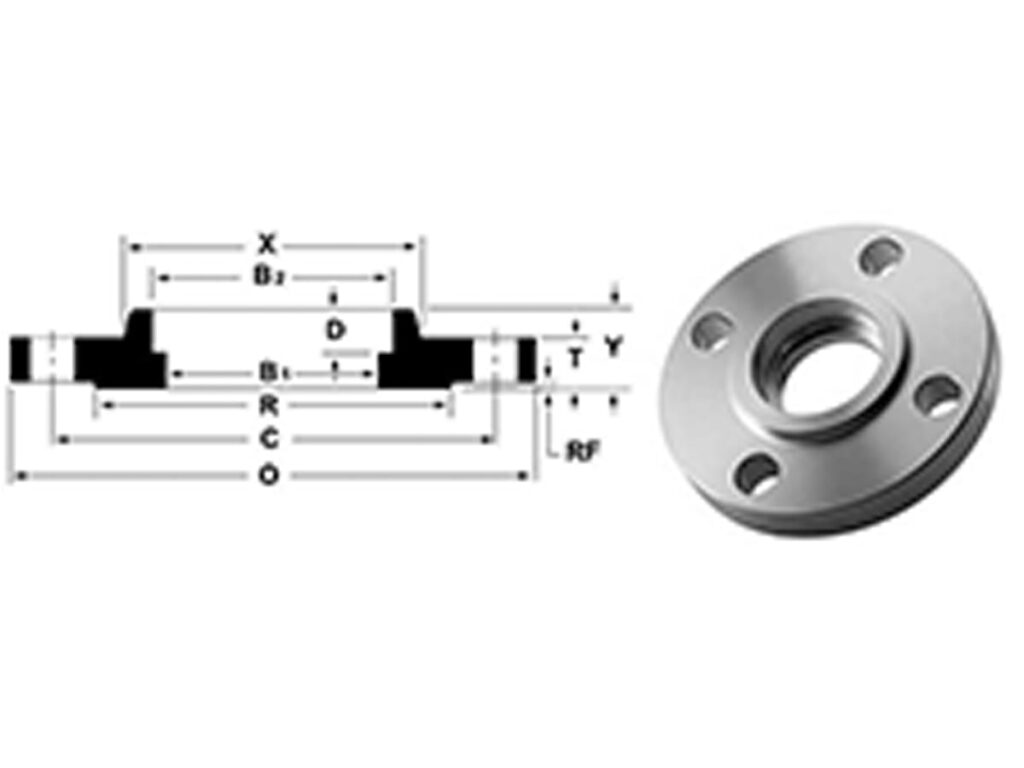

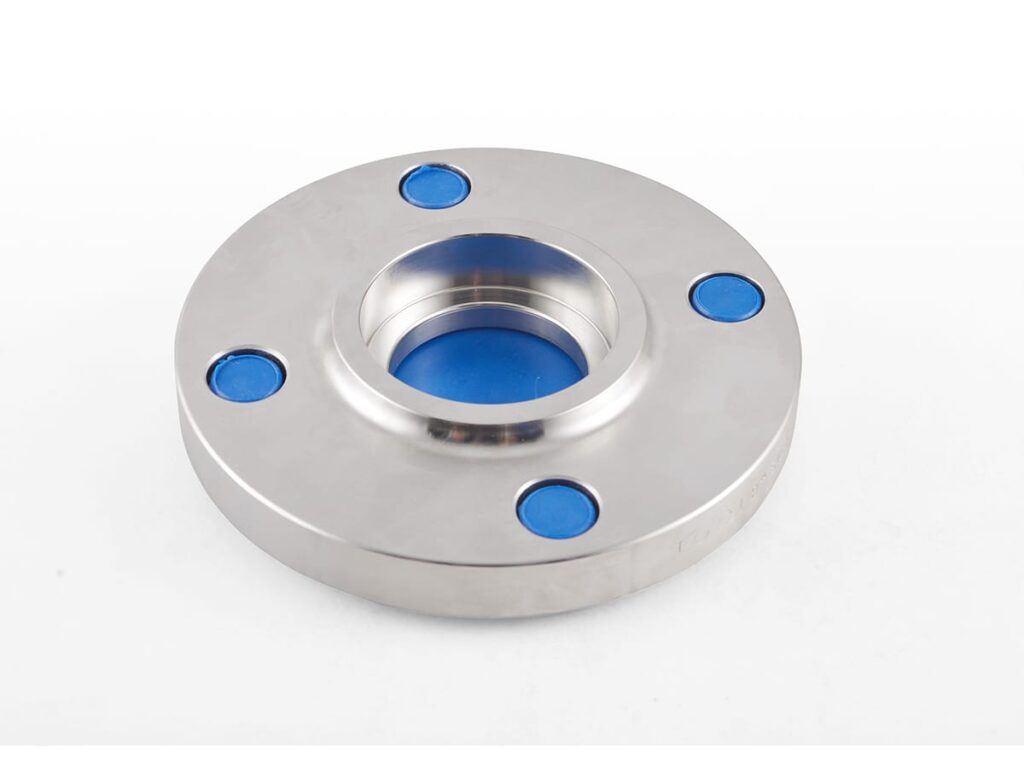

Socket welding flange refers to a flange in which the end of the pipe is inserted into the flange ring step and welded on the pipe end and outside.

There are two types: with neck and without neck.

The flange with neck tube has good rigidity, small welding deformation and good sealing performance.

It can be used in situations where the pressure is 1.0~10.0MPa.

Type B flange for containers is also a socket welding flange and is used in situations with high sealing requirements.

During design, the socket welding flange can be calibrated as an integral flange.

Standard for socket weld flanges

Socket weld flanges are not specified in ASME class 2500 rating as per the ASME B16.5 standard.

The ASME B31.3 standard states that an approximate gap of 1⁄16th of an inch (1.5mm) between the socket and pipe end is required.

Carbon steel ASTM A105, ASTM A350 LF1/2, ASTM A181

Alloy steel ASTM A182 F5, F9, F11, F22, F91

Stainless steel ASTM A182 F304/L, F316/L

Socket welding flange process

Professional overall forging, forging manufacturing, etc.

Application of socket welding flange

Boiler and pressure vessel, petroleum, chemical industry, shipbuilding, pharmaceutical, metallurgy, machinery, stamping elbow, food and other industries.

Socket welding flange: commonly used in pipelines with PN≤10.0MPa and DN≤40;

The socket weld usually has less strength resistance in comparison to butt weld fittings.

So, SW fittings are used mainly for the smaller pipeline with diameters NPS 3 or less when available.

Material of socket welding flange

Carbon Steel: ASTM A105, 20#, Q235, 16Mn, ASTM A350 LF1, LF2 CL1/CL2,LF3 CL1/CL2, ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65, F70;

Stainless steel (Stainess Steel): ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8;

Alloy Steel: ASTM A182 F1, F5a, F9, F11, F12, F22, F91, A182F12, A182F11, 16MnR, Cr5Mo, 12Cr1MoV, 15CrMo, 12Cr2Mo1, A335P22, St45.8/Ⅲ;

Processing method of socket welding flange

High-precision CNC lathe turning, ordinary lathe finishing, argon arc welding and other processing.

Advantages and Disadvantages of Socket Weld Flange

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Ease of Installation | – Simple and quick to install. | – Requires proper alignment for welding. |

| Space Limitations | – Suitable for small pipe diameters. | – Not ideal for large pipe diameters. |

| Strength | – Good strength due to socket weld and fillet weld. | – Weaker than butt-welded connections. |

| Leak Resistance | – Offers good leakage prevention. | – Susceptible to corrosion and erosion at the joint. |

| Cost | – Generally cost-effective. | – Can be more expensive than slip-on flanges. |

| Radiographic Testing | – Easier to perform radiographic testing. | – More challenging to achieve high-quality welds. |

| Cleaning and Inspection | – Easy access for inspection and cleaning. | – Welded area may trap contaminants. |

| High-Pressure Applications | – Suitable for high-pressure systems. | – Not recommended for extremely high pressures. |

At Metleader, our unwavering commitment to class and innovation is reflected in our wide range of socket weld flanges.

As a well-known socket welding flange manufacturer in China, we pride ourselves on being able to provide customized answers that precisely meet our customers’ specific business needs.

Explore the wide range of materials we offer, including Hastelloy DIN 2.4602 Socket Weld Flanges and Super Duplex DIN 1.4410 Socket Weld Flanges, and discover our unparalleled reliability and precision that sets us apart in the global market.

As the China Socket Weld Flange supplier you rely on, we guarantee that your products will most effectively meet but exceed industry requirements.