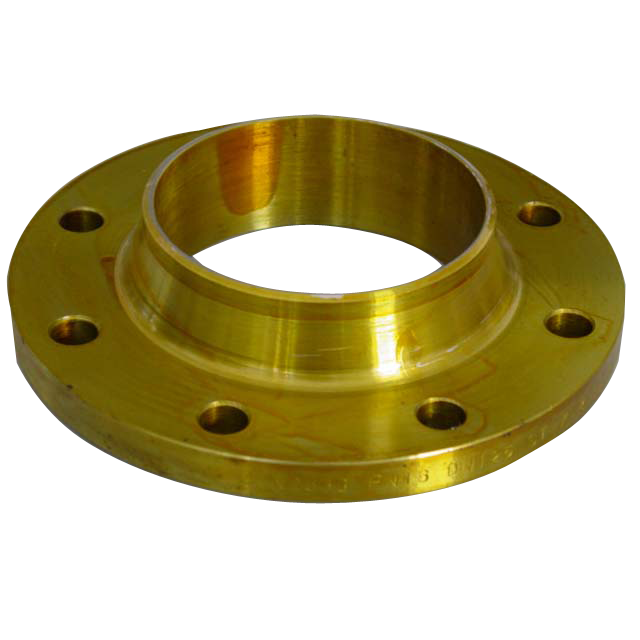

Stainless steel long weld neck flange

What is stainless steel weld neck flange?

Stainless steel weld neck flange including stainless steel long weld neck flange, reducing weld neck flange two kinds. It is mainly suitable for flange and pipe butt welding. Its structure is reasonable, strength and stiffness is larger, can withstand high temperature, high pressure and repeated bending and temperature fluctuations.

Weld neck flange is not easy to deform, good sealing, widely used, nominal pressure PN1.0MPa~PN25.0MPa.

What is stainless steel long weld neck flange?

It is a simply stainless steel high neck flange, generally said that long neck flange is divided according to the American standard. National standard weld neck flange compared with American standard butt welding flange appearance above the neck will be shorter.

It is suitable for high pressure pipeline, pressure vessel flange. So it’s called a long weld neck flange.

| Dimensions | 1/2 “to 24” |

| Classes | 150LB, 300LB, 600LB, 900LB, 1500LB, 2500LB |

| Sealing surface type | Convex surface (RF), concave surface (FM), convex surface (M), tenon surface (T), groove surface (G), full plane (FF) |

| Material | ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8 |

| Execution standard | HG/T20615-2009、ASME B16.5、ANSI B 16.47 |

Application:

It is mainly used in harsh working conditions, such as pipe thermal expansion or other loads to make the flange by the stress or stress changes repeatedly, pressure, temperature fluctuation of the pipeline or high temperature, high pressure and zero low temperature pipeline.

The connection form:

The connection form of American standard butt welding flange is the same as that of national standard butt welding flange. The neck is welded, flange gasket is added to the sealing surface, and the bolt hole is tightened with bolts.

Stainless steel long weld neck flanges features

- Because of its stainless steel material can be acid and alkali resistance, anti-corrosion, high temperature resistance, corrosion resistance and so on.

- There are corresponding rigid and elastic requirements and reasonable welding thinning transition, welding from the joint surface distance, joint surface from welding temperature deformation.