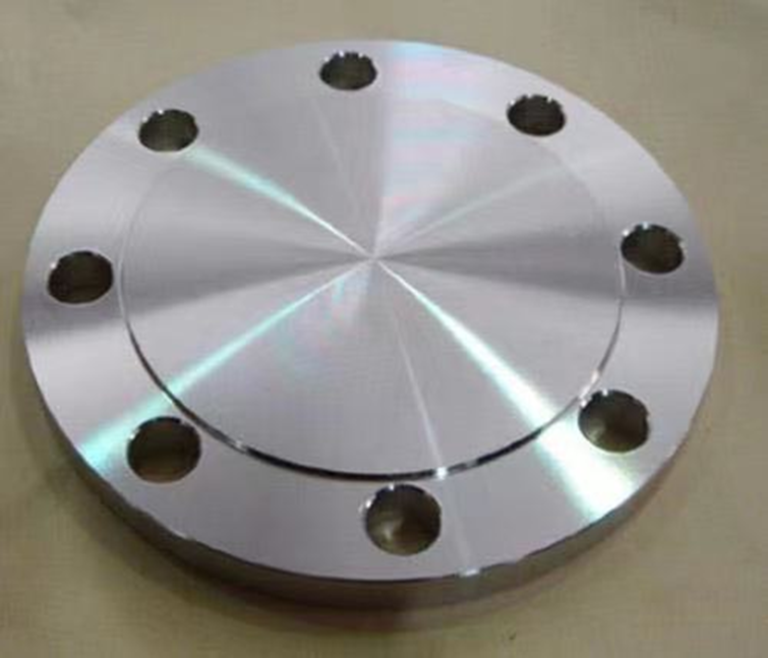

Stainless steel weld neck flange

Stainless steel weld neck flange

What is stainless steel weld neck flange ?

Stainless steel weld neck flange refers to a flange with cone neck and butt welding with cylinder or pipe. Belongs to integral flange.

Due to the transition structure of the cone neck and butt welding connection, the strength and stiffness of the flange are strengthened, and the tightness is better than that of the flat welding flange. The disadvantage is to use forgings manufacturing, consuming materials, manufacturing costs. Suitable for high pressure, high temperature or high sealing requirements.

Production process of stainless steel weld neck flange

Stainless steel weld neck flange is generally made of forging or forging process. When steel plate or section steel is used, the following requirements must be met:

- Weld neck flange should be ultrasonic inspection, no delamination defects;

- It should be cut into strips along the steel rolling direction, after bending welding into a ring, and make the surface of the steel ring formation of the cylinder. Steel plate shall not be machined directly into weld neck flange;

- The butt weld of the ring shall adopt full penetration weld;

- The weld neck flange ring should be heat-treated after welding, and 100% ray or ultrasonic inspection should be made, and the ray inspection should meet the requirements of JB4730 level II, and the ultrasonic inspection should meet the requirements of JB4730 level I;

- The lateral slope of the neck of the weld neck flange should be no more than 70°.

Stainless steel weld neck flanges dimensions

Standard: HG20592~20615-97.

Specifications: 1/2 “to 24”.

Classes: 150LB, 300LB, 600LB, 900LB, 1500LB, 2500LB.

Sealing surface forms of weld neck flange are:

Convex surface (RF), concave surface (FM), convex surface (M), tenon surface (T), groove surface (G), full plane (FF).

Advantages and disadvantages of stainless steel weld neck flange:

Advantages:

The connection is not easy to deformation, good sealing effect, widely used, suitable for temperature or pressure fluctuation of the pipeline or high temperature, high pressure and low temperature pipeline, also used to transport expensive medium, flammable and explosive medium, toxic gas pipeline.

Disadvantages:

Stainless steel weld neck flanges are bulky, heavy, expensive and difficult to install and locate, so they are more likely to knock during transportation.