Applications, standards and technical parameters of plate flanges

Plate type flat welding flange (chemical standard HG20592, national standard GB/T9119, mechanical JB/T81): easy to obtain materials, simple to manufacture, low cost, and widely used; but the rigidity is poor, so it should not be used in areas where supply and demand are high, flammable, and easy to use.

Chemical process piping systems with explosive and higher vacuum requirements and highly and extremely hazardous situations.

The sealing surface types include flat and raised surfaces.

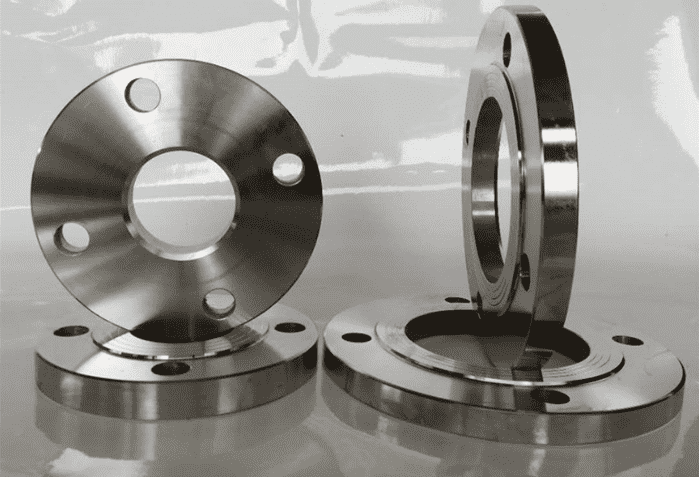

Introduction to plate flat welding flange

Plate flat welding flange is the most common flange, with pressures of PN2.5, PN6, PN10, PN16, and PN25.

Welding form: Plate flat welding flange is to insert the pipe into the flange and weld it.

Material of flat welding flange: 201, 304.316.316L.0Cr18Ni9.321.202, carbon steel, 20#, 20G, and alloy steel, etc.

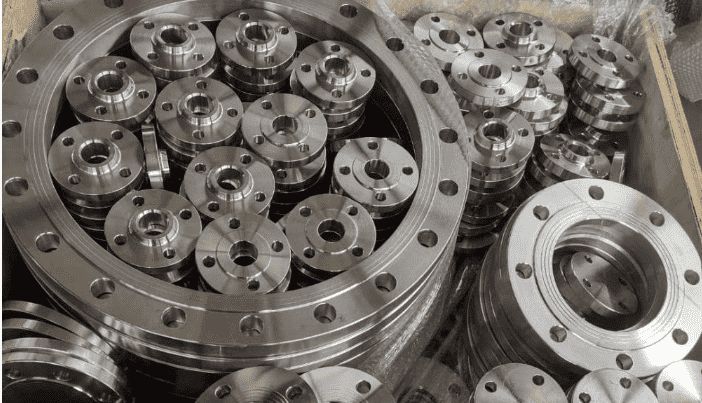

Scope of application of plate flat welding flange

Because the plate flat welding flange has good comprehensive performance, it is widely used in chemical industry, construction, water supply, drainage, petroleum, light and heavy industry, refrigeration, sanitation, plumbing, fire protection, electric power, aerospace, shipbuilding and other basic projects.

Plate flat welding flange standard

| Specification | Plate Flat Welding Flange (ANSI/ASME B16.5) |

|---|---|

| Nominal Sizes | 1/2″ to 24″ and larger (up to 60″ for some classes) |

| Pressure Ratings | Class 150, 300, 600, 900, 1500, 2500 |

| Materials | Carbon steel, stainless steel, alloy steel, etc. |

| Facing Type | Raised face, flat face |

| Facing Finish | Smooth, serrated |

| Flange Facing Dimensions | According to ASME B16.5 standards |

| Connection Type | Welded |

| Temperature Range | Varies based on material and class |

| Marking | Manufacturer’s name or trademark, pressure class, material, size |

Technical parameters of plate flat welding flange

The sealing surface forms of flat welding flanges are as follows:

Concave and convex surface (MFM) DN1300~3000 DN300~3000 DN400~2000 DN300~800

Tongue and groove surface (TG) DN1300~3000 DN300~3000 DN300~3000 DN300~800

Full plane (FF) DN300~3000 DN300~3000 DN300~3000 DN300~800