The processing of steel pipes

Introduction

Since steel pipes are very strong, they are usually used underground for transporting water and gas throughout cities and towns. They are also employed in construction to protect electrical wires.

While steel pipes are strong, they are also very light. This makes them perfect for use in bicycle frame manufacture. Other places they find utility is in automobiles, refrigeration units, heating and plumbing systems, flagpoles, street lamps, and medicine to name a few.

With so many possible uses, you may wonder how steel pipes are manufactured. So, here is an overview of the steps of processing steel pipes.

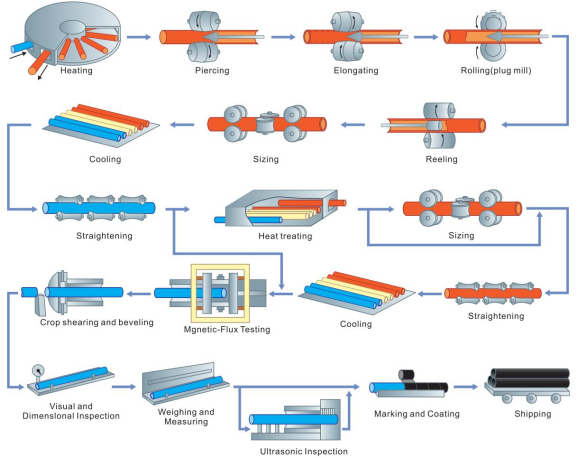

Steel pipe processing diagram:

The processing of steel pipes:

1.Steel-making

This step is in order to get the steel billet that will be used for producing steel pipe. The quality of steel billet is directly up to the quality of steel pipe. So steel-making is a key chain for getting high quality steel pipe.

2. Heating billet

The steel billets should be put into the annular furnace as different heat numbers. And the workers must record the exact heating time and heating temperature. Especially the heating temperature is very important for the quality of pipe.

3. Piercing, rolling, sizing and straightening

The four steps are continuously after these the blank pipes can be gotten.

4. Heat treatment

Heat treatment can improve the mechanical properties of pipes. However, controlling the heat temperature strictly is very important during this step. Overheating will destroy the metal structure and mechanical properties of pipes.

5. The second sizing and straightening

The size and straightness of pipes are probably affected due to the heat treatment, so the second sizing and straightening are necessary.

6. NDT and Hydrostatic test

These tests can guarantee the pressure and no leak of the pipes.

7. Cutting & beveling, visual and dimensional inspection

These will guarantee the size and length of pipes can meet customers’ requirements.

8. Coating &marking and package

After this step the finished pipes will be prepared for shipment.