Things to note when purchasing stainless steel pipe bends

Contents

- Understand the material of stainless steel pipe bends

- Choose the appropriate specifications

- Consider the purpose

- Price factors

- Bend quality requirements

- Physical performance requirements

- Surface quality requirements

- Dimensional deviation requirements

- Quality inspection

- Precautions

- Summary

Bending pipes is a complex processing technology that requires consideration of many factors and requirements.

At the same time, it is also necessary to follow the correct process flow and specifications to ensure the quality and safety of the pipes.

Understand the material of stainless steel pipe bends

There are many kinds of materials for stainless steel pipe bends, the most common of which are 304 and 316 stainless steel. 304 stainless steel has good corrosion resistance and high temperature resistance, suitable for use in general environments; while 316 stainless steel has better corrosion resistance and high temperature resistance, suitable for use in marine and chemical environments.

Therefore, when purchasing stainless steel pipe bends, it is necessary to choose the appropriate material according to the specific use environment.

Choose the appropriate specifications

There are many specifications for stainless steel elbows, including elbow angle, diameter, wall thickness, etc.

When purchasing, you need to choose the appropriate specifications according to actual needs to ensure that the stainless steel elbow can perfectly fit your equipment.

Consider the purpose

Stainless steel pipe bends are suitable for many different industries and fields, including petroleum, chemical, food processing, medical, etc.

When purchasing, it is necessary to consider the specific use of the stainless steel elbow in order to choose the appropriate material and specifications.

Price factors

When purchasing stainless steel elbows, price is not the only consideration. Equally important are the quality of the product and the service. Don’t just focus on price and ignore other important factors.

Bend quality requirements

Physical performance requirements

- The material of the elbow should comply with the provisions of national standards and should have sufficient strength, toughness and plasticity to meet the requirements of use.

- The elbow should have a certain pressure resistance and should be able to withstand a certain pressure and impact during use.

- The elbow should have good corrosion resistance to prevent premature damage in a humid and corrosive environment.

Surface quality requirements

- The surface of the bent pipe should not have obvious scratches, dents, sand holes, bubbles and other defects, as well as scratches and hanging wires on the inner wall.

- The surface of the bent pipe should be smooth and flat, without obvious burrs and saw teeth.

Dimensional deviation requirements

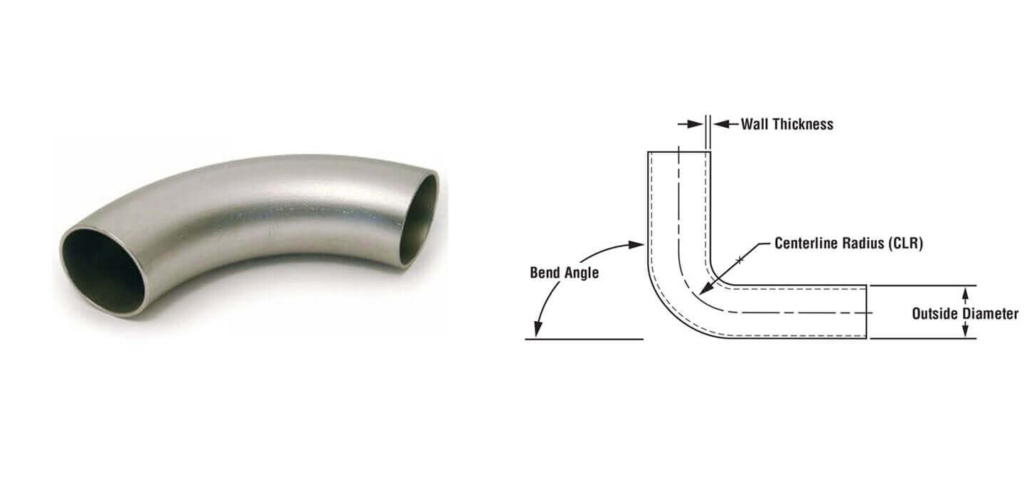

- The bending radius and angle of the elbow should meet the design requirements.

- The outer diameter, inner diameter and wall thickness of the elbow should meet the standard requirements.

- The length of the elbow should meet the requirements and allow a certain deviation.

Quality inspection

- The quality inspection of bent pipes generally includes appearance quality inspection and physical performance testing.

- Appearance quality inspection can be carried out by visual observation, microscopic inspection, flaw detection and other inspection methods.

- Physical performance testing can be carried out by tensile test, bending test, compression test, hardness test and other related test methods.

Precautions

- When purchasing bent pipes, you should choose regular manufacturers and sales channels.

- When purchasing bent pipes, you should pay attention to whether the quality and performance of the materials meet the standard requirements, otherwise it will affect the use effect.

- When inspecting the quality of bent pipes, you should pay attention to whether the surface quality and dimensional deviation of the bent pipes meet the standard requirements.

- If conditions permit, it is best to go to the manufacturer for on-site inspection in person to ensure that the quality of the bent pipes meets the requirements.

- Pay attention to choosing the appropriate bending processing technology and choose the appropriate bending material according to the use requirements.

Summary

As an important industrial accessory, pipe bending requires stable and reliable quality during use.

In order to ensure the quality of pipe bending, we need to understand the quality requirements and quality inspection methods of pipe bending, and pay attention to some important issues when purchasing.

Only in this way can we ensure that the pipe bending can achieve the expected effect during use.