Threaded flange

What is threaded flange?

The threaded flange is a kind of non-welded flange, the inner hole of the flange is machined into pipe thread, and with threaded pipe matching connection.

Compared with welding flanges, threaded flanges are easy to install and maintain, so it can be used for some pipes that are not allowed to be welded on site.

Advantage:

- No welding required

- Easy installation

- Easy repair

It can be used on pipes that do not allow welding, are not easy to weld or have poor weldability.

Disadvantage:

- Large thickness

- High cost

It is suitable for high pressure pipeline connection.

threaded flange production and Supply Range :

- Standard: ASTM, ANSI ASME B16.5

- Material: Carbon Steel, Stainless Steel and Alloy Steel.

- Size Range: 1/2”, 1”, 2”, 3”, 4” , 6″, 8″ to 24”

- Pressure Class: Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500, Class 2500.

- Face: Raised face (RF), Ring type joint (RTJ).

Though it is available in different dimensions, it is mostly used for small diameters pipes.

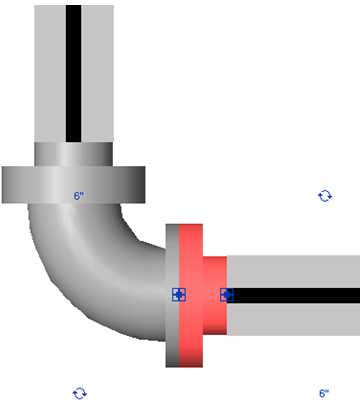

Products Display:

Application of threaded flange:

Threaded flange is not easy to deform, seal well, widely used, nominal pressure PN in 16MPa. So It is mainly used in fire, gas, hot and cold water, air conditioning, air pressure pipe, oil pipe, instrument, hydraulic pipe and other industrial and civil pipe screw lock tight seal.

Threaded flanges are produced and used in accordance with certain principles and principles, to ensure that it can be used in the right way and method, and can provide good use value and function.

Matters need attention:

- When the pipe temperature changes rapidly or the temperature is higher than 260 ° C and lower than -45 ° C, do not use it to avoid leakage.

- Considering the structural characteristics, it is not suitable for flammable and explosive situations.