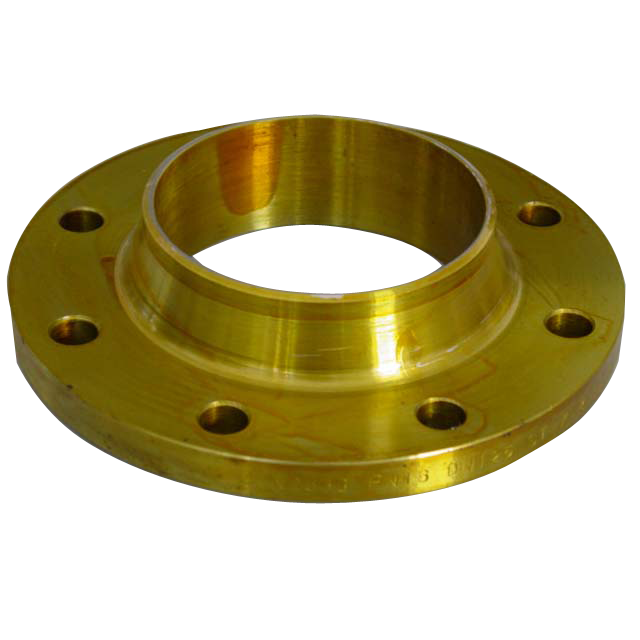

Weld Neck Flange (Carbon & Stainless Steel)

What is weld neck flange?

Weld neck flange is mainly used in the installation of pipelines. The connection of Weld neck flange is an important connection mode of pipeline construction, and the connection between pipes plays an important role and value.

It is produced and used in accordance with certain pipe-related principles to ensure that it can be used in the correct way and method to provide good value and function. Firstly, It is suitable for pipeline with large fluctuation of pressure and temperature, or pipeline with high temperature, high pressure and low temperature. In addition, It is also suitable for conveying expensive, flammable and explosive medium on the pipeline.

Characteristics:

- Not easily deformed

- Good sealing

- Widely used

- Nominal pressure PN in 16MPa

Two Shapes of Weld Neck Flanges

Weld neck flange has two forms (shape), one is with a neck we call reducing weld neck flange; The other is a typical long-neck flange with uniform diameters are called long neck welded flange.

Reducing Weld Neck Flanges

It is like a combination of pipe reducer and flange, so it can be welded directly into smaller pipes.

Long Weld Neck Flanges

Long weld neck flanges are actually an extended form of weld neck flange. Flange neck micro straight cylinder type and is not processed groove, neck height take 229mm(≤DN100) or 305mm(> DN100). They are often used in class series pipe flanges. When the pipe flanges with nominal size less than or equal to DN50 are matched with the cylinder body, They can also avoid the welding difficulties caused by the thin wall thickness of the flange neck end.

Characteristics:

The neck height is higher, and the stiffness and bearing capacity of the flange are improved.

WN Flange vs LWN Flange:

Compared with WN flange, LWN flange has large welding workload, high electrode consumption, and can not withstand high temperature and pressure, repeated bending and temperature fluctuations. However, the site installation is more convenient, can omit the weld patting and kneading process, and is more popular.

Application:

Boiler pressure vessel, petroleum, chemical, shipbuilding, pharmaceutical, metallurgy, machinery, stamping elbow food and other industries.

Our Supply Range

Material: Carbon and Stainless Steel

Standards: ASTM A105, ASTM A182

Sizes: 1/2” to 24”, Customized up to 48”

Pressure Ratings: Class 150, Class 300 to 2500

Wall Thickness: SCH5S, SCH10S, SCH10, SCH40S,STD, XS, XXS, SCH20,SCH30,SCH40, SCH60,SCH80, SCH160, XXS and etc.