Weld neck flange

Weld neck flange

What is weld neck flange?

It is a kind of pipe fitting, which refers to a flange with a neck and a round pipe transition and connected with the pipe butt welding.

It is not easy to deformation, good sealing, widely used, there are corresponding rigid and elastic requirements and reasonable welding thinning transition, welding distance from the joint surface, joint surface from welding temperature deformation.

Application scope:

Weld neck flange is not easy to deform, good sealing, widely used, there are corresponding rigid and elastic requirements and reasonable butt welding thinning transition, welding from the joint surface distance is large, joint surface from welding temperature deformation. It takes a more complex shape structure, suitable for pressure or temperature fluctuation pipeline or high temperature, high pressure and low temperature pipeline, generally used for PN greater than 2.5MPa pipeline and valve connection; It is also used for conveying expensive, flammable and explosive media on the pipeline.

Common production standards:

Ministry of Chemical Industry standard HG/T20592-2009, HG/T20615-2009.

National standards GB/T9115.1-2000, GB/T9115.2-2000, GB/T9115.3-2000, GB/T9115.4-2000.

Mechanical department standard JB/T86.2-94.

Marine standard CB/T47-1999.

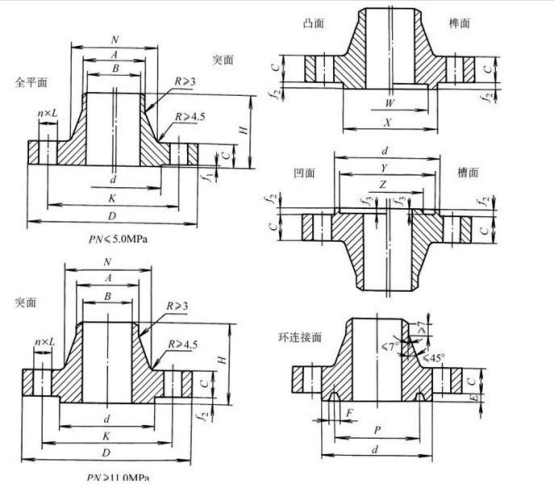

Sealing surface forms of weld neck flange are:

Convex surface (RF), concave surface (FM), convex surface (M), tenon surface (T), groove surface (G), full plane (FF).

Advantages:

The connection is not easy to deformation, good sealing effect, widely used, suitable for temperature or pressure fluctuation of the pipeline or high temperature, high pressure and low temperature pipeline, also used to transport expensive medium, flammable and explosive medium, toxic gas pipeline.

Disadvantages:

Weld neck flange are bulky, heavy, expensive and difficult to install and locate, so they are more likely to knock during transportation.